Channels lising page

All videos archived of HVAC School

W6LKnHYmmYU | 16 Feb 2026

Join us at the 7th Annual HVAC/R Training Symposium as we explore cutting-edge test instruments with UEI! In this sponsor booth interview, we sit down with Louise Kellar from UEI Test Instruments to discuss two game-changing products for HVAC technicians. Featured Products: UEICLIP Personal CO Monitor - A wearable carbon monoxide detector designed for technician safety. This set-it-and-forget-it device features reading range of 1-300ppm, both a loud audible alarm and red flashing light. Includes both lanyard and belt clip options for maximum convenience while you work. Advanced Combustion Analyzer - UEI's upgraded analyzer includes all three sensors (O2, CO, and CO2) for direct readings, an enhanced flue probe with integrated draft measurement, and a crisp, upgraded display screen. UEI Service Plus Guaranteed Program: Annual recertification with extended warranty Transparent pricing (know costs upfront) Same-day turnaround from Indianapolis facility FREE shipping both ways Don't let carbon monoxide catch you off guard - the UEICLIP monitor ensures you're protected in any environment, even unexpected ones. Learn more: https://www.ueitest.com/ecommerce/default.aspx Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

CaalOqjjY8I | 15 Feb 2026

Learn how to install a toilet with our comprehensive 3D animated guide! This complete tutorial walks you through every step of replacing a residential toilet from start to finish. Follow our step by step guide for professional results. What You'll Learn: Complete tools and materials checklist Proper shut-off and water removal techniques Safe removal of old toilet and wax ring Flange inspection and repair methods Professional wax ring installation techniques Proper leveling and shimming procedures Tank assembly and water supply connection Leak testing and troubleshooting Professional caulking and finishing touches Proper disposal methods Key Topics Covered: Toilet replacement | Wax ring installation | Closet bolt replacement | Flange repair | Water supply line connection | Professional plumbing techniques | Bathroom renovation | DIY toilet install | Toilet leveling | Leak prevention Perfect for HVAC technicians, plumbers, handymen, contractors, and DIY homeowners looking to master professional toilet installation techniques. #ToiletInstallation #Plumbing #HVACSchool #DIYPlumbing #HomeRepair #BathroomRemodel #PlumbingTips #ToiletRepair #3DGuide #professionalplumbing Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

T6Hc1-w6kQs | 12 Feb 2026

Join Bryan Orr at AHR Expo 2026 in Las Vegas as he visits the Copeland booth to get a hands-on demo of the new Sensi Equipment Interface Module (EIM) from Jim Fultz. In this interview, Jim demonstrates how the Sensi EIM solves a common HVAC upgrade challenge: converting existing systems to heat pumps without running new wire. Watch as Bryan connects the Equipment Interface Module to a Sensi thermostat in real-time, showcasing the automatic pairing feature and simple setup process. Key topics covered in this Demo: Automatic pairing - no button pushing required Converting AC systems to single-stage heat pumps Wireless communication between thermostat and outdoor unit Dual fuel functionality and changeover logic Reversing valve configuration (O vs B terminal) Real-world heating call demonstration The Copeland Sensi EIM is perfect for retrofit applications where adding conductors isn't practical. Jim walks through the complete setup from pairing to configuration to making heat calls, proving how easy this module makes heat pump conversions. Learn more about Copeland: https://www.copeland.com/en-us Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

MAePlTqVy-I | 10 Feb 2026

Join Bryan Orr for a comprehensive NAVAC Full Booth Tour at AHR Expo 2026! This walkthrough showcases NAVAC's latest innovations in HVAC tools and equipment.🔧 Featured in this booth visit: NEXUS Manifolds - Digital/analog configurations Recovery Machines Measurequick Integration Probe Kits with flexible bag configurations Condensate Pumps Vacuum Technology Cordless Vacuum Pumps with onboard micron gauges This AHR Expo 2026 walkthrough covers everything from residential HVAC tools to industrial vacuum applications. NAVAC demonstrates why they're a leader in recovery machines, manifolds, and vacuum pump technology. More info: https://navacglobal.com/transcript Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

GG0NqPk-nY4 | 10 Feb 2026

Join Bryan Orr at AHR Expo 2026 in Las Vegas as he sits down with Tony Gonzalez from Fieldpiece to discuss their new line of Analog Manifold Gauges. Discover why these durable, professional-grade gauge sets are essential backup tools for every HVAC technician's truck. Key Features Discussed: Available in 3-port and 4-port configurations Designed for popular refrigerants (R-22, R-32, R-454B, R-410A) Specialized refrigeration gauge sets available Innovative ratcheting pressure-hold feature for long-term pressure testing Extremely durable construction built for field use Ideal for teaching new technicians Perfect backup when digital tools fail Great for dirty systems and burnt-out compressors Whether you're looking for a reliable backup tool, teaching apprentices, or need something tough for challenging jobs, these Fieldpiece analog manifolds deliver professional performance at a competitive price point. More info: https://www.fieldpiece.com/ Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

DtINXanblJw | 08 Feb 2026

Learn the essential skills for capillary tube repair and brazing in this comprehensive HVAC training class with Roman. This hands-on capillary tube brazing class covers everything technicians need to know about working with these critical metering devices. What You'll Learn: How capillary tubes meter refrigerant through friction and pressure differential Understanding inner diameter (ID) vs outer diameter (OD) and why it matters Proper sizing charts and BTU capacity calculations Step-by-step capillary tube brazing techniques Common mistakes and how to avoid them When to repair vs replace capillary tubes Working with different wall thicknesses and refrigerant types Insertion depth best practices (1/4" to 1/2") Heat application and avoiding kinks or breaks Key Topics Covered: Capillary tube fundamentals and metering principles Friction-based pressure drop mechanics Proper brazing techniques for delicate copper tubing Caliper measurements and sizing tools Oil return applications in VRF systems Schrader core connections Field repair scenarios and troubleshooting Whether you're a new HVAC technician or experienced professional, this capillary tube repair and brazing class provides practical knowledge you can apply immediately in the field. Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

xJyMoR4B3rk | 07 Feb 2026

Discover the latest innovation in whole-home dehumidification! In this exclusive interview from the 7th Annual HVAC/R Training Symposium, Roman from HVAC School sits down with Nikki Krueger from Santa Fe to explore the groundbreaking Ultra V-Series Dehumidifiers. KEY FEATURES COVERED: Enhanced Ventilation - Upgradedduct for optimal outdoor air intake Digital Controls - New intuitive control interface for precise humidity management Wired Remote Sensor - No batteries needed! Low-voltage installation in living spaces More Powerful Fan - Handles increased static pressure on supply side Built-in Float Switch - Automatic shutoff protection for overflow prevention MERV 13 Filtration - Superior air quality included standard Flexible Humidity Settings - Choose 40%, 45%, 50%, or 55% RH setpoints PROBLEM SOLVED: Contractors were previously forced to oversize dehumidifiers or add costly booster fans to achieve proper ventilation rates. The Ultra V-Series eliminates these workarounds with its powerful 8-inch ventilation system, delivering the right CFM for optimal indoor air quality without compromise. PRODUCT HIGHLIGHTS: The Santa Fe Ultra V-Series represents years of contractor feedback transformed into engineering excellence. With digital controls replacing traditional stats, installation flexibility has never been better. The optional remote sensor mounts anywhere in the living space, providing accurate humidity readings where it matters most. Learn more about Santa Fe dehumidifiers: https://www.santa-fe-products.com/ Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

lm3SgwUvugA | 06 Feb 2026

Join Bryan Orr at AHR Expo 2026 as he sits down with Andrew Greaves from NAVAC for an in-depth discussion about vacuum pump gas ballast operation, maintenance, and moisture management. In this deep dive, Andrew breaks down common misconceptions about the gas ballast valve and explains its true purpose. Learn why it's NOT for priming your pump or making hoses easier to remove – discover the real science behind keeping moisture in vapor form during evacuation. Key Topics Covered: The truth about gas ballast function and when to use it How moisture affects vacuum pump oil and performance Understanding two-stage rotary vane pump operation Proper vacuum pump maintenance and oil change intervals Gas ballast valve service and rebuild kits When opening the ballast actually helps vs. hurts performance Andrew uses NAVAC's interactive classroom approach to visually demonstrate how gas flows through first and second stage pumps, why oil degradation happens with moisture contamination, and how to properly maintain your vacuum pump tools. Whether you're experiencing pump overheating on wet systems or just want to understand the science behind proper evacuation practices, this technical session delivers practical knowledge you can apply immediately. Learn more: https://navacglobal.com/ Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

iolNPvbP6ZM | 05 Feb 2026

Join Bryan Orr from HVAC School for an exclusive booth visit at AHR Expo 2026, where he sits down with John Pastorello, the legendary founder of Refrigeration Technologies. In this inspiring interview, discover 50 years of HVAC innovation straight from the man who revolutionized leak detection and created industry-standard products like Big Blue. What You'll Learn: How a field technician's frustration with leak detection sparked a company The origin story of Big Blue bubble leak detector and why it changed the industry John's transition from chemist to HVAC technician to manufacturer The fascinating development of Nylog and how discarded oil & gas research became an HVAC game-changer Why John Pastorello received the Lifetime Achievement Award at the 2026 AHR Expo Insights on staying independent: the truth about private equity in HVAC manufacturing Real research before Google: libraries, patent offices, and kitchen table experiments About John Pastorello: Starting as an air conditioning service mechanic in the early 1970s, John combined his chemistry background with field experience to solve real problems technicians face daily. Founded in 1987, Refrigeration Technologies has made the Inc 5000 list as one of America's fastest-growing manufacturers for four consecutive years—a testament to innovation-driven growth. Featured Products Discussed: Big Blue Bubble Leak Detector Nylog Gasket & Thread Sealant Viper Refrigerant Leak Detector This AHR Expo 2026 interview covers everything from 1970s HVAC contracting to modern manufacturing excellence, offering valuable lessons for technicians, contractors, and business owners alike. More About Refrigeration Technologies: Website: https://www.refrigtech.com/ Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

rIPg1MqRha4 | 03 Feb 2026

Join us at the 7th Annual HVAC/R Training Symposium as Bert from HVAC School sits down with Jim Fultz from Copeland/White-Rodgers to discuss their innovative HotRod Combo Kit! Discover why this Hot Surface Nitride Ignitor combined with a Flame Sensor in one kit is changing the game for furnace tune-ups and maintenance. Jim breaks down the science behind flame sensor degradation - explaining how repeated cleaning actually makes the surface rougher and causes contamination to build up faster. Learn valuable installation tips including: Why you should replace BOTH the ignitor and flame sensor during tune-ups The "finger test" rule for proper flame sensor placement How to properly clean and install flame sensors for optimal performance Why flame sensors don't last forever despite common belief This White-Rodgers combo kit includes everything you need - hot surface igniter, flame sensor, and flexible insulation - making furnace service calls more efficient and profitable. Captured live at the HVAC/R Symposium, this interview provides real-world insights from industry professionals who are passionate about helping technicians succeed in the field. More info: https://www.copeland.com/en-us/brands/white-rodgers Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

hZYjqeohCbU | 01 Feb 2026

Learn everything about HVAC thermistor training including proper testing methods, common failures, and splicing techniques in this comprehensive guide. This HVAC thermistor training covers NTC (Negative Temperature Coefficient) sensors used in refrigeration and HVAC systems. What You'll Learn: HVAC thermistor testing methods using resistance measurements Common thermistor failures: moisture infiltration, overheating, wire rubout, and corrosion Why thermistors typically fail HIGH in HVAC applications Understanding 10K, 20K, and 200K thermistor types The 77°F (25°C) reference point for all thermistors Proper splicing techniques and connection methods for thermistor replacement How to identify thermistor types without charts Applications in walk-in coolers, mini-splits, and temperature control systems Key Topics Covered: HVAC thermistor testing with multimeters Resistance-to-temperature relationships Common failure modes and diagnostics Proper wire connections (solder vs crimp vs wire nuts) Moisture-related failures and prevention Using resistors as temporary troubleshooting tools Service applications and real-world scenarios Perfect for HVAC technicians looking to master thermistor diagnostics and replacement in commercial refrigeration and HVAC systems. Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

-IlL-60pjyg | 21 Jan 2026

Discover how to properly test electronic expansion valves using the EEVMate tool in mini splits and VRF systems. Roman Baugh demonstrates testing both direct drive and indirect drive EEVs, showing you how to bypass the PCB board and manually actuate valves to diagnose internal component failures. What You'll Learn: Identifying the two types of electronic expansion valves (direct drive vs. indirect drive) How to use the EEVMate manual driver tool for hands-on testing Testing EEVs electrically with a multimeter Manually actuating expansion valves to check for stuck or failed internal components Using turbo mode to diagnose and potentially free stuck valves in mini splits Proper cable connections and common wire identification Key Features of the EEVMate Tool: Manual EEV actuation capabilities for VRF systems and mini splits Turbo mode for 10x faster valve driving Compatible with most electronic expansion valves One-handed operation with battery caddy Multiple cable adapters available Perfect for HVAC technicians troubleshooting: Mini split systems with electronic expansion valves VRF (Variable Refrigerant Flow) systems Inverter equipment using the EEVMate tool for testing EEV Troubleshooting in 3D: A Guide for HVAC Techs: https://www.youtube.com/watch?v=fd0kGz0XckE Available at www.trutechtools.com Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

vkjuUq8lA8o | 14 Jan 2026

Master the fundamentals of HVAC drain lines in this comprehensive training session covering installation techniques, troubleshooting methods, and best practices for preventing the number one callback issue in HVAC service: condensate drain problems and costly water damage. What You'll Learn: Understanding drain traps and why they're critical for proper condensation removal Double trap identification and diagnosis - the hidden culprit behind recurring drain issues Proper drain line pitching requirements (1/4 inch per foot minimum) Vent placement and when venting is required to prevent airflow blockage Insulation requirements for PVC and copper drain lines to prevent condensation Float switch positioning and adjustment for optimal safety shutdown Common installation mistakes that lead to costly water damage callbacks Horizontal vs vertical unit drain configurations and professional setup methods Secondary drain pan setup and support requirements Coil orientation (left vs right) and proper drain pan alignment Troubleshooting intermittent drain failures and callback prevention strategies Key Topics Covered: Negative pressure systems and trap requirements for HVAC systems Avoiding double traps in attic runs and vertical installations Proper condensate pump installation with trapping best practices Why drain lines should never tie into sewer systems Common scenarios in townhomes and apartments Filter access considerations when installing float switches Preventing water damage between floors with proper drain line techniques Perfect for HVAC technicians, installers, and service professionals looking to eliminate drain-related callbacks and master proper condensate drainage. Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

lSQ0fbalQd0 | 11 Jan 2026

Join us for an authentic look at How to Fix Attic Humidity Problems with Santa Fe Ultra Series Dehumidifier in a real home with 10 kids and serious moisture challenges. This comprehensive guide shows you exactly how the Santa Fe Ultra120 Ventilating Dehumidifier solves humidity issues in closed-cell foam attics. What You'll Learn: Why moisture gathers at attic peaks due to high grit buoyancy Proper Santa Fe Ultra Series installation techniques How to connect supply and return ducts correctly The importance of powered dampers vs backdraft dampers How to avoid reducing AC latent capacity Real-world performance after 7-8 years of operation Key Installation Details: MERV 11 filtration setup 6-inch vs 8-inch duct sizing (older vs newer models) Proper condensate pan switch and trap installation Sound dampening techniques This Santa Fe whole house dehumidifier has been running reliably for nearly 8 years, handling extreme internal moisture loads from cooking, laundry, and daily activities. Learn why the Santa Fe Ultra series is the go-to solution for professional HVAC technicians. Perfect for HVAC professionals, homeowners, and contractors dealing with attic humidity, crawl space moisture, or whole-home dehumidification challenges. Santa Fe V155 Whole House Dehumidifier Install: https://www.youtube.com/watch?v=r0MtEiJ5MYw&t=1045s Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

VR7BdPdTT7o | 07 Jan 2026

Master the critical difference between Continuity vs Resistance testing! This essential HVAC Multimeter Skills training covers proper techniques for diagnosing compressors, motors, and inverter boards, plus essential Diode Testing fundamentals. What You'll Learn: Why continuity mode FAILS for compressor ground testing The proper resistance range for checking grounded compressors (0-50Ω continuity vs 0-50MΩ resistance) How to avoid misdiagnosing good compressors as bad Diode testing fundamentals for inverter board troubleshooting Proper multimeter selection and settings for HVAC diagnostics Key Takeaways: Continuity Mode: For checking circuits that SHOULD be connected (switches, closed contactors, wire continuity) Resistance Mode: For checking circuits that SHOULD NOT be connected (compressor grounds, motor windings to ground, insulation) #HVACTraining #MultimeterTesting #CompressorDiagnostics #HVACTechnician #ElectricalTroubleshooting #HVACEducation #ResistanceTesting Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

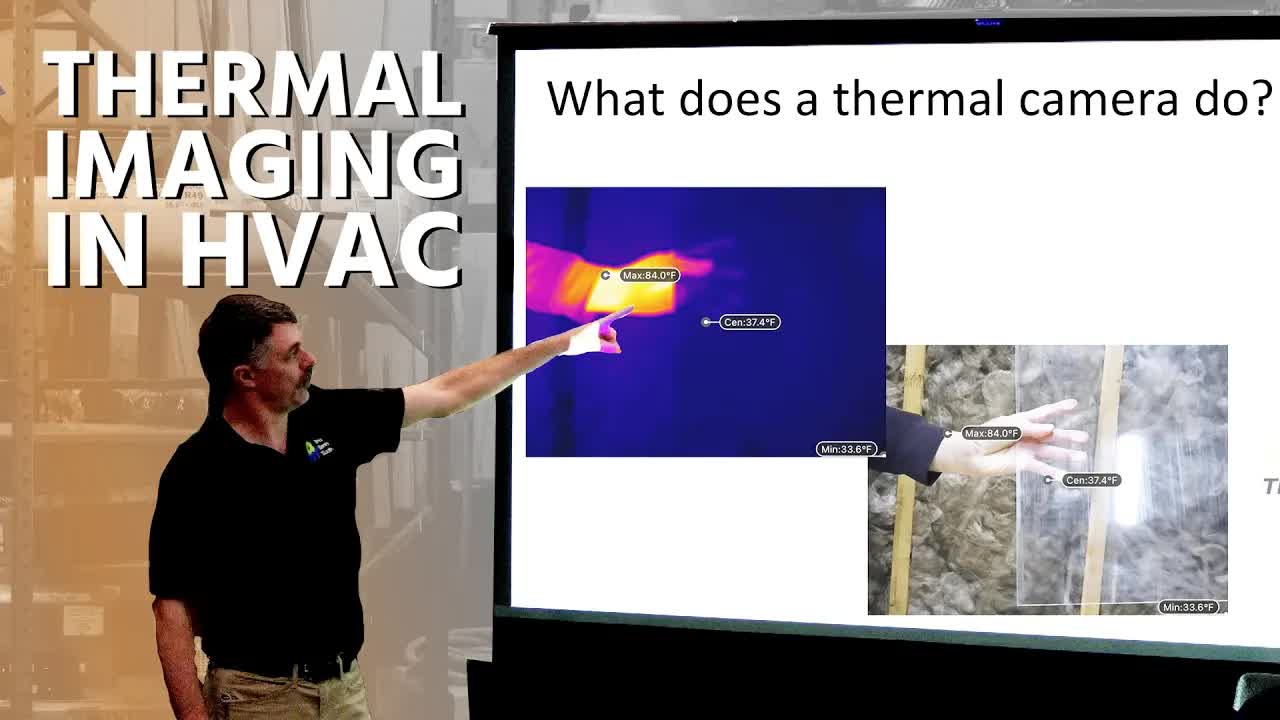

4yn2Wf9s3oY | 04 Jan 2026

Master your thermal imaging camera with this complete guide designed specifically for HVAC techs! This training for service technicians covers everything you need to know about thermography in the field. Learn how to use thermal imaging cameras effectively for HVAC diagnostics, maintenance, and upgrades. What You'll Learn: Circuit breaker panel inspections and electrical safety checks Detecting leaking ductwork in attics and crawl spaces Finding insulation gaps and building envelope issues Identifying moisture problems behind walls and tiles Visual subcooling assessment on condensers without gauges Spotting thermal bridging and energy loss areas Window efficiency testing and air leakage detection How to turn thermal imaging findings into profitable service upgrades Key Topics Covered: Understanding emissivity and reflective surfaces Proper distance and measurement techniques Comparing temperature differentials effectively Thermography as both art and science Building customer trust with advanced diagnostics Safety protocols for electrical inspections Perfect for residential and commercial HVAC technicians looking to add value to maintenance visits and improve diagnostic accuracy. Learn practical applications that help you identify problems other techs miss! #HVACTraining #ThermalImaging #HVACTech #Thermography #HVACDiagnostics #ServiceTech #HVACMaintenance #hvacschool Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

LQhkH5hpHOI | 17 Dec 2025

When your AC system is not keeping up during extreme hot weather, knowing how to diagnose the issue and communicate effectively with customers is crucial. This essential HVAC training video covers professional troubleshooting techniques and customer communication strategies for heat wave scenarios. What You'll Learn: Comprehensive diagnostic procedures when AC units run continuously without reaching setpoint Understanding system limitations in hot weather conditions above 93°F Liquid line temperature approach testing for evaluating condenser performance How to confidently assess when an AC system is actually working properly despite high indoor temperatures Professional customer communication methods that prevent callbacks and build trust Technical Skills Covered: Measuring and interpreting approach temperatures (liquid line vs outdoor ambient) Blower speed adjustments for improved performance Superheat and subcool readings during extreme conditions Condenser coil inspection and cleaning verification Understanding heat transfer rates and compounding effects in extreme heat Documentation practices using measurement tools and apps Customer Service Excellence: Setting realistic expectations without under-promising or over-delivering inappropriately Explaining why systems struggle keeping up when outdoor temps exceed design conditions Identifying home envelope issues: air leaks, insulation problems, and heat load factors Offering whole-home diagnostic services for comprehensive solutions Balancing technical confidence with professional humility This training helps HVAC technicians avoid the callback trap while maintaining customer trust during the most challenging service conditions of the year. Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

c9YAwSHJDCI | 07 Dec 2025

In this video, Bryan Orr introduces and demonstrates the Fast-Stat Common Maker, an innovative solution for HVAC professionals who need to add a common wire to existing systems without running new thermostat cable. The Common Maker consists of two main components - a receiver unit that installs in your equipment cabinet and a sender unit that goes behind the thermostat. This device is compatible with all 24V AC HVAC systems including furnaces, boilers, gas valves, and Aquastat controls, allowing WiFi and smart thermostats to operate reliably without batteries. Bryan walks through what's included in the box and explains how to create a working common wire connection using your existing thermostat cable. Learn more about Fast-Stat products at fast-stat.com or purchase online at hvacrschool.com/fast-stat. Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

vClBnw3m9hQ | 03 Dec 2025

In this comprehensive HVAC training video, we explore why compressors fail and provide expert guidance on diagnosis techniques, replacement procedures, and prevention strategies to avoid costly callbacks. Key Topics Covered: Main causes of compressor failures Acid contamination and why "ACID-AWAY" products don't work Proper acid cleanup procedures with filter driers Checking refrigerant charge and standing pressure Oil return issues and lubrication problems Floodback vs. starvation conditions Flooded starts and crankcase heaters Hard start kits: when they help and when they hurt Essential electrical components for replacement during changeout Contamination from copper shavings, moisture, and particulates Long line set considerations and manufacturer requirements Critical Diagnosis Steps: Static pressure testing Acid testing procedures Weighing recovered refrigerant Inspecting electrical connections Evaluating airflow and filter conditions Wire damage and high voltage issues Learn the proper prevention methods and replacement best practices to ensure compressor longevity. Master the diagnosis of failed compressors and understand what truly causes them to fail. Compressor Oil Overheat - What Happens When Oil Is Cooked To Its Limit: https://www.youtube.com/watch?v=NV62EQ8D1MY Start Winding and Capacitor Crankcase Heater: https://www.youtube.com/watch?v=RA0rNWpxJkU #HVACTraining #CompressorFailure #CompressorReplacement #hvacdiagnostics Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

doFMdvr38Vw | 16 Nov 2025

Learn essential HVAC condensate drain maintenance techniques to prevent costly water damage callbacks. This comprehensive training covers float switch wiring in series vs parallel configurations, proper installation methods, and troubleshooting common drain issues. Key Topics Covered: Float switch wiring: series vs parallel configurations and why it matters Water damage prevention in horizontal and vertical HVAC applications Unit leveling and proper drain pan pitch Diagnosing wet air handlers: frozen coils, high static pressure, cracked pans Standing water test for leak detection Drain clearing methods: vacuum, water hose, and snake techniques Identifying roof leaks vs drain problems Condensation issues on platforms and panels Proper insulation and sealing techniques Critical Safety Points: Why drains are the #1 callback issue Testing float switches during maintenance Documentation best practices When to use nitrogen vs water for clearing drains Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

uufw46osvdQ | 14 Nov 2025

In this video Roman Baugh demonstrates the game-changing D-TEK® Pro from INFICON, 0.1 PPM Industry Leading Refrigerant Leak Detector! This powerhouse device delivers is 10x better resolution than D-TEK Stratus®, detecting leaks down to 0.1 PPM. Key Features: 0.1 PPM Industry Leading Refrigerant Leak Detector sensitivity - 10x more accurate than D-TEK Stratus® Supercharged sensor eliminates dilution concerns Bluetooth app connectivity with GPS-tagged reports 12-hour battery life for all-day leak detection No mode selection needed - just power on and go Live graphing and professional client reports Bluetooth audio alerts for noisy environments Lightweight at 3 lbs with 3-foot wand Watch as we demonstrate real-world leak detection in multiple buildings, showing instant response times and precise PPM readings. See how this Industry Leading Refrigerant Leak Detector identifies leaks from 4-5 feet away and provides the accuracy HVAC technicians need to trust their diagnostics. Perfect for commercial refrigeration rack houses, rooftop units, package units, and residential systems. The D-TEK® Pro comes in a rugged hard case and includes phone holder accessories for hands-free operation. Find out more at: https://www.trutechtools.com. How to Find Refrigerant Leaks: https://www.youtube.com/watch?v=uITUze-vBZA #HVAC #RefrigerantLeakDetector #DTEKPro #HVACTools #LeakDetection #HVACTech #TruTechTools Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

lc5oMcjHdio | 12 Nov 2025

In this comprehensive training video, we provide valuable Crankcase Heaters and Refrigerant Charging tips that can make or break your repair job: Proper Refrigerant Charging Techniques Why charging location matters: Learn the difference between charging into the suction line vs. liquid line System off vs. system running: Best practices for each scenario Preventing compressor damage: How improper charging can cause oil foaming and premature compressor failure The automotive analogy: Why short oil circulation is like running a new car engine without proper lubrication Crankcase Heater Wiring and Operation Understanding crankcase heater purpose: Why they prevent refrigerant condensation in the compressor Single pole vs. two pole contactors: Critical wiring differences that affect heater operation Electrical theory explained: How the crankcase heater uses compressor windings as additional heating elements Common wiring mistakes: What happens when you replace a single pole with a two pole contactor Solutions and workarounds: Proper fixes and temporary solutions for field situations Key Takeaways: Always charge refrigerant into the liquid line when the system is off Verify crankcase heater operation after compressor replacement Use proper single pole contactors for crankcase heater circuits Always weigh refrigerant to identify potential leaks Think holistically about system problems and root causes Pro Tips Covered: How to bypass a two pole contactor temporarily (and why you shouldn't) The White-Rodgers SureSwitch contactor by Copeland advantage Why weighing refrigerant can reveal hidden leaks Importance of addressing root causes, not just symptoms Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

jUeYV-SvR8I | 09 Nov 2025

This video explains the DEADLY Deadly Consequences For Compressors that occur when brazing copper lines without flowing nitrogen . Watch as we demonstrate exactly what happens inside your system when you skip this critical step and how it can KILL your compressors. What You'll Learn: The devastating effects of brazing without nitrogen protection How copper oxide formation creates deadly contamination in your system Real-time demonstrations showing different oil types cleaning copper oxide The true cost of skipping nitrogen during brazing procedures How copper oxide particles destroy compressor components over time Why filter dryers can't save you from this deadly mistake DEADLY Consequences Explained: Copper oxide flakes circulating through your entire system Contamination that leads to premature compressor failure TXV restrictions and superheat problems Acid formation and copper plating on moving parts Why systems die within years instead of lasting decades Scientific Evidence: We put different oils (mineral, POE, PVE) to the test, showing you under a microscope exactly what happens when oil flows through oxidized copper lines. The results will shock you - especially when you see how aggressively modern POE oils strip contamination from copper surfaces. The Real Cost: Skip $7 worth of nitrogen and face thousands in compressor replacements, callbacks, and reputation damage. This video proves why proper brazing techniques are non-negotiable for professional HVAC technicians. Key Takeaways: Always flow nitrogen when brazing - no exceptions Understand why RX11-flush won't solve your copper oxide problems Learn the difference between cleaning contamination and preventing it See why proper installation practices prevent 98% of compressor failures Master the fundamentals that separate professionals from parts changers Whether you're brazing residential split systems or commercial equipment, this video will change how you approach every joint. Stop gambling with compressor life and start following the science-backed practices that ensure system longevity. Don't let deadly brazing mistakes destroy your reputation - watch now and master the proper techniques that protect your systems and your business! Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

0wAhrieYofY | 05 Nov 2025

Master the heat pump defrost cycle and critical heat strip wiring safety protocols with this comprehensive HVAC heating season preparation guide! Essential training for technicians getting ready for winter service calls. What You'll Learn: Heat Strip Wiring Safety Undersized wire dangers and fire hazards Proper wire gauge sizing for heat kits Correct breaker and wire combinations Common retrofit issues when replacing furnaces with heat pumps Heat Pump Defrost Cycle Explained Thermostat vs thermistor defrost systems Standard carrier defrost boards Demand defrost boards with coil and ambient sensors How to test defrost operation in the field Troubleshooting Defrost Issues Testing defrost sensors and thermistors Identifying ice buildup vs normal frost Diagnosing premature or stuck defrost cycles Manual defrost testing procedures Setting Customer Expectations Explaining normal defrost sounds and cold air When defrost is working properly vs system failure Why units make "horrible sounds" during defrost switching Key Safety Reminders: Undersized wiring causes wire melt and potential house fires Always verify wire gauge matches heat kit requirements Check for rodent damage on defrost sensor wiring Maximum 10-minute defrost cycles on standard boards Perfect for HVAC technicians, service professionals, and students preparing for heating season service calls. This comprehensive guide covers both safety and diagnostic procedures you need in the field. #HVACTraining #HeatPump #DefrostCycle #HVACSchool #HeatingSeason #HVACSafety #HeatStrip #HVACTech #HVACService #hvactroubleshooting Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

gGZcydG6tQg | 02 Nov 2025

Learn essential De-escalation Strategies for HVAC technicians dealing with upset customers. This video covers practical strategies for managing tense situations, from understanding the psychology behind customer emotions to specific communication techniques that work. Discover how to listen empathively, find common ground, and remember that customer frustration often stems from factors beyond the immediate HVAC issue. Whether you're dealing with installation problems, repair delays, or misunderstandings, these proven de-escalation methods will help you maintain professionalism while resolving conflicts effectively. Perfect for both new and experienced HVAC professionals looking to improve their customer service skills. Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

7vZIkC9RerY | 29 Oct 2025

In this video our techs demonstrate Ecobee Smart Thermostat Setup process and discuss the usage of thermostats for Two Stage Systems. You will also find some guidance on Client Support best practices when dealing with queries about Smart Thermostats. This HVAC training will help you properly configure Ecobee thermostats for optimal performance and customer satisfaction. What You'll Learn: Ecobee Smart Thermostat Setup procedures from start to finish Two Stage Systems configuration and staging optimization techniques Critical installation settings including humidity control (52-54% recommended levels) Equipment sizing considerations for oversized systems Dehumidifier integration and relay state management Configure staging options for enhanced runtime and dehumidification Client Support Excellence: Learn proven strategies for exceptional Client Support when installing Ecobee Smart Thermostats. Discover how to educate customers about new technology features, manage expectations with data interpretation, and focus conversations on comfort rather than numbers. Essential techniques for avoiding callback situations and ensuring customer satisfaction with Two Stage Systems. Professional Tips: Always read the manual for proper airflow considerations Set "Hold to Action" preferences to prevent accidental temperature changes Update firmware before field installation to avoid version conflicts Focus client conversations on comfort levels, not technical data Allow adjustment period for customers transitioning from older thermostats Perfect for HVAC technicians working with Ecobee Smart Thermostat Setup, Two Stage Systems installations, and anyone seeking to improve their Client Support skills in residential HVAC applications. Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

HWX8wnr29aE | 26 Oct 2025

Learn the most effective strategies of How to Handle Price Objections in this comprehensive HVAC Sales Training session from HVAC School. Master the art of overcoming customer resistance and closing more deals with confidence. What You'll Learn: Price objection handling techniques that actually wor The psychology behind customer objections and how to address them Value-based selling strategies for HVAC technicians Active listening skills to identify the real customer concerns Warranty explanation best practices without sounding defensive How to position yourself as a skilled professional worth the investment Key Training Points: HVAC pricing strategies - Focus on technician value, not part costs Customer communication - Listen first, respond with confidence Professional positioning - You're paying for expertise and overhead Warranty vs. price objections - Learn to distinguish between different customer concerns Role-playing techniques - Practice scenarios before facing upset customers Sales confidence building - Stay grounded when customers get emotional Featured Topics: HVAC technician training for field service professionals Service call pricing explanations and justifications Parts markup discussions and value proposition Customer service excellence in challenging situations HVAC business operations overhead cost explanations Field service sales closing techniques Perfect for HVAC contractors, service technicians, field service managers, and anyone in the residential HVAC industry looking to improve their sales skills and customer interactions. Manufacturer Responsibility – Manifesto: https://www.hvacrschool.com/podcasts/manufacturer-responsibility-manifesto/ Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

r0MtEiJ5MYw | 22 Oct 2025

Join HVAC School as we walk through a Santa Fe V155 Whole House Dehumidifier Install in a Florida home experiencing serious humidity issues! This tutorial walks you through installing the V155 dehumidifier system to solve oversized AC unit problems that weren't providing adequate humidity control. What You'll Learn: Santa Fe V155 whole house dehumidifier installation process How to identify and solve humidity problems caused by oversized HVAC systems Proper ductwork connections including dedicated return and supply integration Electrical installation requirements and outlet setup Using Santa Fe's innovative hanging kit system for attic installations Control system setup with external humidity controls Static pressure testing to ensure optimal performance Professional sealing techniques using mastic and proper insulation Key Features Covered: V155's 10-inch return and supply connections Fresh air intake option with motorized damper Magnetic filter door access with MERV 13 filtration Internal vs external control options This real-world installation demonstrates why proper humidity control is essential in Florida's climate, where oversized AC units cool too quickly without adequate dehumidification. Perfect for HVAC technicians, contractors, and anyone looking to understand whole house dehumidifier systems. Training Opportunity: Watch our HVAC and electrical apprentices gain hands-on experience while learning alongside experienced HVAC professionals in this collaborative learning environment. Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

K9e8cNdtK2g | 19 Oct 2025

Discover the shocking truth about compressor oil dangers that every HVAC technician needs to know! Can compressor oil really melt plastics? The answer will surprise you. In this eye-opening experiment Roman Baugh and Ty Brannaman reveal how refrigeration oils create a phenomenon called "crazing" that can seriously damage PVC and ABS plastics in your HVAC systems. What You'll Learn: The hidden compressor oil dangers affecting your equipment How POE and PVE oils can literally melt plastics over time What is crazing and how it differs from cracking Why your drain pans and PVC drain lines are at risk Real-world examples of oil-damaged HVAC components Critical cleanup procedures to prevent plastic degradation Unintended consequences of oil contamination in systems Key Discoveries: Our scientific experiment shows that compressor oil doesn't just stain - it actually penetrates plastic at the molecular level, causing swelling and creating microscopic stress lines that look like shattered glass. This crazing effect weakens PVC drain lines, ABS plastic components, fan shrouds, electrical connections, and more. We tested POE (Polyolester) and PVE (Polyvinyl Ether) oils and found both create identical damage patterns. The oil impregnates the plastic surface, causing molecular bond separation that progresses deeper over time until complete failure occurs. Critical Applications: Leaky evaporator coils contaminating drain pans Oil washing down PVC drain lines during normal operation Contaminated fan motors, shrouds, and electrical connections Rooftop unit cleanup after compressor failures Proper degreasing techniques for contaminated systems This isn't just about aesthetics - oil-damaged plastics can cause loose electrical connections, system failures, and expensive repairs. Learn why cleaning up oil spills immediately is crucial and which cleaning products are safe for different materials. Professional Tips Included: Safe cleanup procedures for roof membrane protection Chemical compatibility considerations for different plastics How to identify crazing vs. normal wear and tear When and how to use degreasers safely Preventing cross-contamination during service calls Whether you're a seasoned HVAC technician or just starting out, this video will change how you think about compressor oil handling. The science behind plastic degradation affects everything from simple cable ties to complex electronic components. Don't let these compressor oil dangers destroy your systems! Watch now to protect your equipment and your customers' investments. Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

NV62EQ8D1MY | 16 Oct 2025

Ever wondered what really happens during compressor oil overheat? In this groundbreaking experiment, we find out What Happens When Oil Is Cooked To It's Limit. Watch as we systematically cook three different types of compressor oil - mineral oil, POE (Polyolester), and PVE (Polyvinyl Ether) - at temperatures reaching 340-350°F to simulate real-world compressor overheat scenarios. What happens when oil is cooked to its breaking point will surprise even experienced HVAC technicians. What We Discovered: Compressor oil breakdown: See actual carbon contamination form in real-time Oil overheat effects: Witness dramatic color changes and particle formation Temperature limits: Learn exactly when each oil type reaches its breaking point Microscopic analysis: View contamination particles under high magnification System implications: Understand how cooked oil damages expansion valves, strainers, and scroll plates Key Findings: Mineral oil started smoking much earlier than expected POE oil showed superior heat resistance compared to mineral oil PVE oil created extensive contamination when pushed to its limit Carbon particles settle at the bottom where oil pumps draw from Oil breakdown happens in minutes, not hours This experiment reveals why high discharge temperatures (245°F+) are so dangerous for compressor longevity. When internal compressor temperatures reach 320-340°F, the oil literally cooks, creating abrasive particles that act like sandpaper on bearings, scroll plates, and other moving components. Safety Warning: This is a controlled scientific experiment conducted with proper safety equipment. DO NOT attempt this at home. Hot oil is extremely dangerous and can cause severe burns or fires. Perfect for HVAC technicians, students, and anyone who wants to understand the real science behind compressor failures. This hands-on experiment provides visual proof of what textbooks can only describe. Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

Jn1yB6m06oQ | 15 Oct 2025

Join us for an exploration of subcooling measurement challenges with R-454B refrigerant and learn practical troubleshooting techniques for HVAC technicians. What You'll Learn: Understanding Condenser Operation: How refrigerant flows through condensers (top to bottom) The three phases of refrigerant in condensers: superheated vapor, condensation and subcooling Temperature and pressure relationships throughout the condensing process R-454B Specific Challenges: Why R-454B behaves differently than traditional refrigerants Understanding blend stratification and density effects in condensers Why gauge readings may not reflect actual refrigerant state with blended refrigerants Advanced Diagnostic Techniques: Using thermal imaging cameras to verify actual condenser performance Understanding reflectivity issues with copper surfaces and thermal readings How to identify liquid stacking in condensers visually Charging Best Practices: Why manufacturers specify subcooling targets (typically 12°F) The relationship between overcharging and increased head pressure How excessive subcooling reduces condenser efficiency The importance of proper documentation when deviating from standard targets Critical Troubleshooting Insights: Why measurement accuracy matters (temperature clamps vs. actual refrigerant temperature) The psychological trap of repeatedly adding charge instead of finding leaks How to balance optimal performance with real-world measurement limitations Key Takeaways: R-454B's blend characteristics can create measurement challenges that don't reflect actual system performance Thermal imaging provides a pressure-independent way to verify condenser operation Proper subcooling isn't just about hitting target numbers—it's about understanding system efficiency Documentation is crucial when systems require non-standard charging approaches Perfect for HVAC technicians working with newer refrigerants and looking to improve their diagnostic skills with blended refrigerants like R-454B. Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

EmaoSUpT9u8 | 08 Oct 2025

Join Brynn Cooksey in the presentation called IAQ for the HVAC Tech. Brynn is a home performance contractor and technical trainer from Michigan, as he reveals how indoor air quality (IAQ) testing transformed his contracting business from "box swapping" to a profitable service model at the 6th Annual HVAC/R Training Symposium. What You'll Learn in the: The IAQ Market Opportunity: Why IAQ is a $10 billion industry that HVAC techs are missing out on How one technician visits 1,000+ homes annually - all potential IAQ customers Why testing IAQ on every service call creates instant profit centers Six Critical IAQ Parameters to Test: Particles (PM 2.5) - The invisible threats that bypass respiratory defenses Chemicals/VOCs - Volatile organic compounds found in 99% of homes tested Carbon Dioxide - Your ventilation quality indicator (aim for under 600 PPM) Carbon Monoxide - Why standard detectors aren't enough (learn about low-level detection) Humidity - Managing the 35-60% sweet spot for health and comfort Temperature - How it reveals other IAQ issues Practical Solutions Covered: Source control strategies (always step #1) Enhanced filtration systems (MERV 13/16 recommendations) Duct cleaning and sealing techniques (including aeroseal technology) Ventilation strategies - "Don't Forget the V!" ERV/HRV systems and controls Real-World Case Studies: How IAQ testing discovered a dangerous CO leak during a water heater service call Before and after results showing dramatic improvements Why 99% of homes tested show VOC problems Key Takeaways: Test first, implement solution, test again - every single call "Control the source" is the #1 principle for IAQ success Ventilation is the "silver bullet" that improves multiple parameters Proper equipment sizing matters more than you think Whether you're looking to escape the "rat race to the bottom" or want to provide genuine value to customers suffering from allergies, asthma, and other IAQ-related health issues, this presentation shows you how to turn IAQ testing into a profitable service offering. Find out more at: https://www.hvacrschool.com/symposium Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

nor8HNgnfmY | 05 Oct 2025

In this detailed HVAC training video, Roman Baugh and Ty Branaman are Comparing Tools and Techniques of Copper Deburring. Using a digital microscope, they examine the actual surface damage caused by various deburring methods to show why technique matters just as much as tool selection. What You'll Learn: Why deburring copper tubing is essential for system efficiency and oil return How burrs create turbulence, reduce efficiency, and cause refrigerant noise Microscopic comparison of needle nose pliers vs. dedicated deburring tools vs. reaming tools vs swage tools The impact of aggressive vs. controlled deburring techniques How poor deburring affects flare quality and connection integrity Best practices for copper cutting to minimize burr formation The relationship between tool maintenance and burr creation Tools and Techniques Covered: Needle nose pliers (traditional method) Dedicated deburring tools Reaming tools Tubing expanders for deburring applications Proper copper cutters and wheel maintenance Key Takeaways: Proper technique is more important than tool selection Dull copper cutter wheels create excessive burrs Aggressive deburring can damage copper and compromise flare integrity Quality work prevents system contamination and connection failures This is skilled trade work - take the time to do it right the first time. Remember: respect your copper, maintain your tools, and never stop learning! Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

AWecM1MfuEE | 01 Oct 2025

Learn essential HVAC troubleshooting techniques for diagnosing air handler noise, sealing cabinet leaks, and measuring static pressure. This comprehensive training covers real-world scenarios that every HVAC technician needs to master. What You'll Learn: Air Handler Sealing Why cabinet gaps and cracks act like "straws" pulling in moisture and dirt How to identify dust tracking patterns that reveal air leaks Proper sealing techniques using silver tape, silicone, and masking tape When and how to use different sealing materials for permanent vs. removable panels Static Pressure Diagnostics Understanding what ECM motors actually "see" vs. total external static pressure How high static pressure damages blower wheels and motors Why you should never just sell a fan replacement without finding the root cause Zonal Pressure Testing Room-to-room pressure measurement techniques using precision manometers Understanding pascal readings and what they mean for comfort and efficiency How pressure imbalances affect humidity, infiltration, and energy costs Real case study: 7 pascal bedroom measurement and customer consultation Advanced Troubleshooting Tips Low suction pressure diagnosis: always start with airflow Using thermal imaging and vane anemometers for ductwork verification Filter bypass issues and upgrade recommendations Connecting equipment problems to building envelope issues Key Takeaways: Noise at air handlers usually indicates sealing problems Air leaks cause moisture infiltration, bypassing filtration, and comfort issues Proper sealing techniques prevent long-term equipment damage Pressure imbalances affect the entire home's comfort and efficiency Always clean surfaces with alcohol before applying tape or sealant This training emphasizes practical, field-tested solutions that technicians can implement immediately. Perfect for both new technicians learning diagnostics and experienced techs wanting to expand their building science knowledge. Tools Mentioned: Precision manometers Vane anemometers Thermal imaging cameras True flow grids Tape squeegees Silver tape, masking tape, silicone sealant Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

NzlsB9R6mbc | 28 Sep 2025

Join Adam Mufich from National Comfort Institute in this game-changing presentation on Fan Law 2 for Techs from the 6th Annual HVAC/R Training Symposium! If you've ever wondered why your replacement equipment sounds like a rocket ship or why heat exchangers keep failing, this session will open your eyes to the critical relationship between airflow and static pressure. What You'll Learn: The Basics: What is CFM and static pressure really? How to measure total external static pressure properly Why inches of water column matters Fan Law 2 Deep Dive: Breaking down the intimidating math into simple terms Fan Law 2 the simplified approach Real-world examples with actual field measurements Game-Changing Applications: Filter pressure drop calculations at different airflows Evaporator coil pressure drop analysis How to predict total external static pressure before installation Backing into TSP using duct pressure measurements Problem-Solving Scenarios: Why replacing a PSC motor with variable speed can create problems How proper equipment sizing dramatically reduces static pressure Component selection strategies for coils and filters Real examples showing 1" static vs 0.64" static with proper planning Key Takeaways: Adam reveals how static pressure and airflow move together but not proportionally - increasing airflow by 16% can increase static pressure by 33%! This explains why so many techs struggle with noisy systems and premature equipment failures. Featured Tools & Techniques: Digital TrueFlow® Grid measurements Fan performance tables and plotting Component pressure drop ratings Strategic filter and coil selection Find out more at: https://www.hvacrschool.com/symposium Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

uIXfiuY3i9U | 24 Sep 2025

Join Alex Meaney in this comprehensive presentation ''Understanding Airflow: David Bowie, a Used Car Lot, and a 40¢ Tool with Alex Meaney'' from the 6th Annual HVAC/R Training Symposium as he breaks down the fundamentals of airflow in HVAC systems using creative analogies and practical demonstrations. What You'll Learn: The Scale Problem in Ductwork Why duct sizing isn't as simple as it seems How cross-sectional area dramatically impacts airflow Understanding Pressure (The "David Bowie" Connection) Static pressure vs. velocity pressure vs. pressure loss vs. external static pressure Why pressure isn't the "bad guy"—friction is The asteroid analogy: how friction affects airflow like atmospheric entry Visual Demonstrations The "used car lot" inflatable tube demo showing static and velocity pressure balance Bathroom scale and crate analogy for understanding energy transfer How energy gets "used" vs "wasted" in duct systems Measuring Airflow The 40¢ manometer: building pressure measurement tools with basic tubing Why we focus on static pressure measurements in residential HVAC Pitot tube basics and velocity pressure measurement challenges Residential vs Commercial Design Philosophy Why residential design works "backwards" from commercial The myth of the 0.08 "magic number" and why there isn't one universal answer How to calculate proper friction rates based on available static pressure Real-World Applications Why 0.1 inches of water column per 100 feet doesn't work in modern systems The impact of modern filters, coils, and unit locations on system design Central air vs "corner air"—the importance of equipment placement Modern Challenges How today's tighter coils, better filters, and larger homes have changed the game Why oversized equipment on undersized ducts seems to "work" (but shouldn't) The importance of using tools like TrueFlow grids instead of relying on customer satisfaction Key Takeaways: Duct sizing is geometric, not linear—small changes have big impacts Friction is your enemy, not pressure Modern residential systems need larger ducts than traditional 0.1 sizing allows Equipment placement dramatically affects duct sizing requirements Proper measurement and testing beats customer complaints as success metrics About the Presenter: Alex Meaney brings years of experience as head trainer for Wrightsoft and a unique perspective with his background in English, communications, and philosophy. His approach focuses on understanding the "why" behind HVAC principles rather than just memorizing formulas. Perfect for HVAC technicians, installers, and anyone looking to understand the fundamental principles behind proper airflow design and troubleshooting. Find out more at: https://www.hvacrschool.com/symposium Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

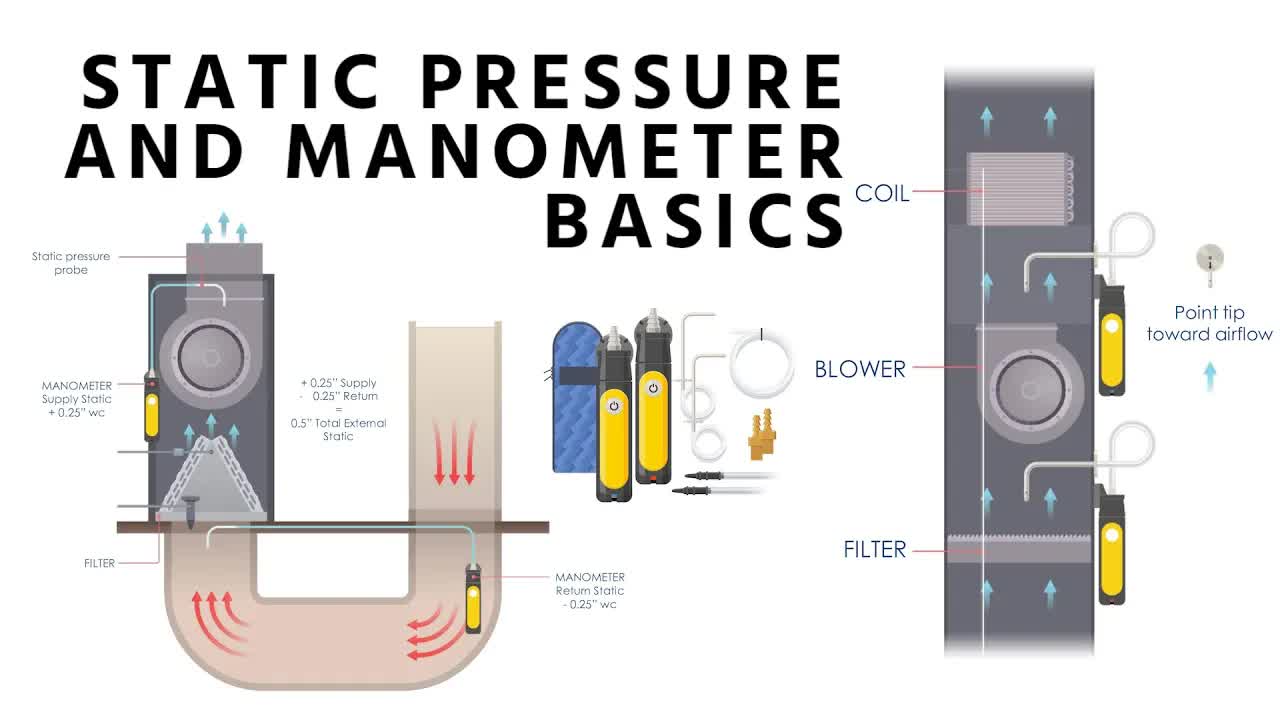

o6OVAUJXeuU | 21 Sep 2025

In this essential HVAC training session, we dive into the Static Pressure Fundamentals - a critical skill every technician needs to master. Learn how to properly measure Total External Static Pressure (TESP) and understand what the numbers really mean for system performance. What You'll Learn: Understanding Total External Static Pressure and industry benchmarks (0.5" WC standard) Proper testing procedures using digital manometers and the MeasureQuick app How to test with and without filters to assess system restrictions Reading return vs. supply pressure measurements Identifying system problems through pressure readings Why balanced airflow is crucial for system efficiency Common ductwork issues that affect static pressure Key Takeaways: Industry standard TESP is 0.5 inches of water column Always zero out your instruments before testing Test both return side (negative pressure) and supply side (positive pressure) High static pressure indicates system breathing problems Data doesn't lie - proper measurements reveal true system performance Perfect for HVAC technicians, installers, and anyone looking to improve their diagnostic skills. Remember: you can't manage what you don't measure! Tools Mentioned: Digital manometers MeasureQuick app Digital TrueFlow® Grid Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

czzb9hsIGXw | 20 Sep 2025

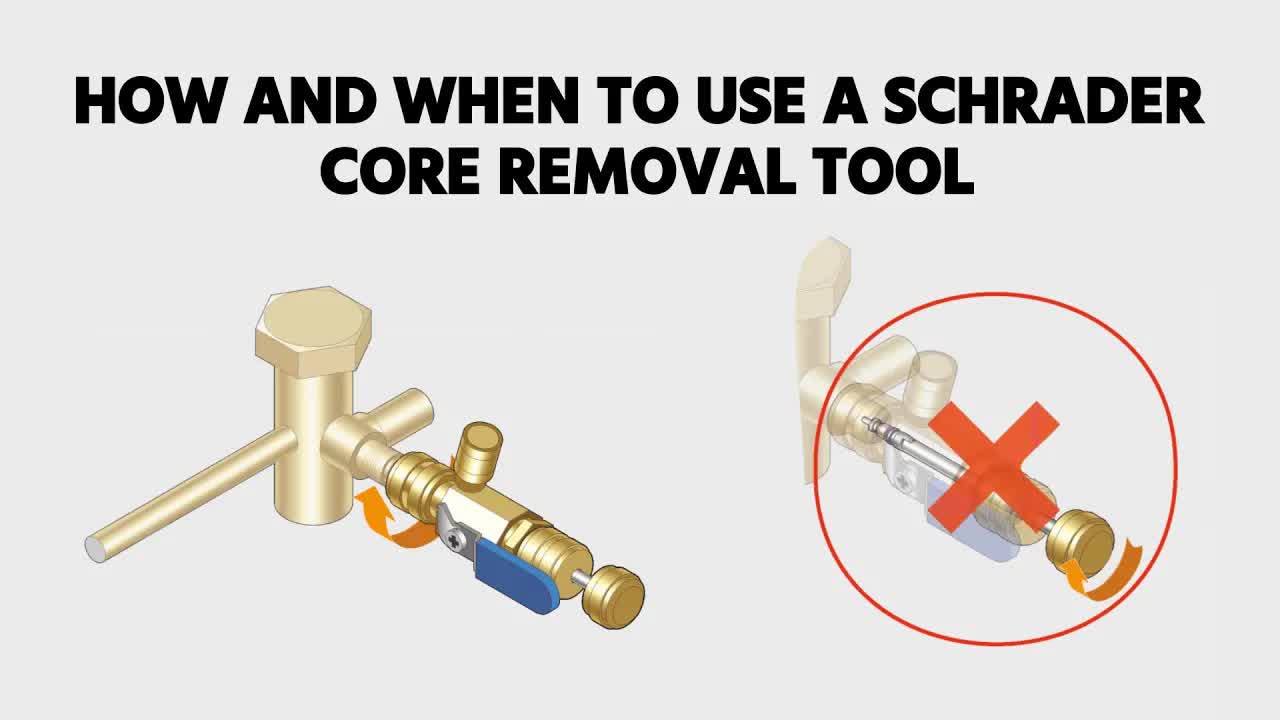

In this video, we're unboxing and reviewing the innovative NAVAC NVR2 Valve Core Removal Tool - a game-changing dual-size tool that handles both 1/4" and 5/16" ports in one compact design! What Makes the NVR2 Special: Dual Size Capability: Works with both 1/4" (standard) and 5/16" (European/Asian brands) valve cores Premium Build Quality: Features a sleek matte black finish High Pressure Rating: Handles up to 800 PSI working pressure (4000 PSI burst pressure) Professional Grade: Perfect for refrigerant recovery, vacuum evacuation, and HVAC service Quality Components: Includes high-quality O-rings with extras provided Warranty Backed: Comes with a full one-year warranty The NAVAC NVR2 eliminates the need to carry separate valve core removal tools for different fitting sizes. Whether you're working on residential systems with R-410A or dealing with European brands like Daikin, this tool has you covered. Key Features Demonstrated: Removable adapter system for size switching Proper installation and removal technique Working pressure specifications and safety margins O-ring maintenance and replacement Perfect for HVAC technicians, refrigeration professionals, and anyone working with valve cores in the field. This tool streamlines your toolkit while maintaining professional performance standards. Find out more: hvacrschool.com/nvr2 Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

Ni1jiSs6kR0 | 14 Sep 2025

Join David Richardson as he breaks down the essential roadmap to high-performance HVAC in this comprehensive presentation from the 6th Annual HVAC/R Training Symposium. Richardson tackles one of the industry's biggest challenges: moving beyond the "box swapping" mentality to true system performance. What You'll Learn: The definition of high-performance HVAC and why it matters The PATH acronym: Pressure, Airflow, Temperature and Heat (BTUs) Why HVAC is more than just equipment - it's about the entire system The three pillars of performance: Safety, Health, and Comfort Step-by-step implementation strategies using the STEPS framework The "One Degree Principle" for gradual, sustainable change Key Takeaways: Richardson emphasizes that high-performance HVAC is about returning to craftsmanship roots while leveraging modern measurement tools. He explains how the average system delivers only 57% of its rated capacity and demonstrates how proper testing and measurement can achieve up to 88% performance improvement. The presentation focuses on practical implementation, starting with static pressure measurement as the foundation, then building toward comprehensive system analysis. Richardson stresses the importance of making changes incrementally, meeting technicians where they are, and avoiding the "fog of uncertainty" that comes from trying to do everything at once. Perfect for: HVAC contractors looking to differentiate their services Technicians wanting to advance their diagnostic skills Anyone interested in moving beyond basic equipment replacement Companies seeking to implement performance-based service offerings This isn't just theory - David Richardson shares real-world experience from implementing these principles since 2000, including common obstacles and practical solutions for overcoming them. Find out more at: hvacrschool.com.com/symposium Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

BK6S3hFwG18 | 10 Sep 2025

Join Chris Hughes from The Energy Conservatory and Adam Mufich from National Comfort Institute as they tackle one of the HVAC industry's most challenging topics: properly commissioning inverter-based equipment. Drawing from their extensive field experience and months of research, they address the confidence gap that many technicians face when working with variable-speed systems. What You'll Learn: The fundamental differences between traditional single/two-stage systems and modern inverter equipment Essential pre-commissioning requirements including outdoor temperature (65-100°F) and indoor temperature (73-80°F) ranges Equipment-specific considerations for different brands, tonnages, and control types Proper charging methods and the critical 20-minute stabilization period How to access test/commissioning modes across various manufacturers Why "just turn the thermostat down to 60°" doesn't work with inverters Key Takeaways: The presenters reveal a major industry problem: inconsistent and often incomplete commissioning information from manufacturers. They share their solution - a comprehensive spreadsheet compiled over months of research that provides startup instructions and commissioning details for nearly every inverter brand on the market. The Challenge: Unlike traditional systems where technicians could confidently know a system was at 100% capacity, inverter systems require specific knowledge of how to properly test compressor speed, indoor fan operation, and outdoor fan modulation - information that's often scattered across multiple manuals or hidden behind dealer portals. This presentation is essential viewing for any HVAC technician working with modern equipment who wants to move beyond guesswork and return to confident, thorough system commissioning. Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

b520p5wG76E | 07 Sep 2025

Is your winter maintenance checklist missing crucial steps? In this practical training, Bert shares essential Winter Furnace & Heat Pump Checking Tips as the cold season approaches. Learn the smart way to test heating systems that will save you callbacks and keep customers happy. Bert covers: Why checking heat FIRST in your service process prevents costly mistakes How to properly test heat at the thermostat (the way customers will use it) Preventing those embarrassing "smoke alarm" calls from dusty heat strips The RIGHT way to check refrigerant charge on cold days (manufacturer charging charts) Tips for adding refrigerant in colder temperatures Whether you're servicing new installations or maintenance calls, these practical steps will help you avoid common winter service pitfalls. Perfect for new techs experiencing their first heating season and veterans looking to refine their process. #HVAC #HVACtraining #furnacemaintenance #heatpumps #wintermaintenance #HVACtips #technicaltraining Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

_xXK26hktu8 | 03 Sep 2025

In this unboxing video, Bryan Orr demonstrates the Fast-Stat Model 5000, an innovative solution that simplifies HVAC system upgrades. This device provides three additional control wires plus a common wire, making it easier than ever to add air conditioning or two-stage heating to existing furnaces, or set up dry contact heating systems with 24-volt relays. Bryan walks through the unboxing process, showing the two main components: the receiver unit (installed inside the equipment cabinet) and the sender unit (installed behind the thermostat). He explains the color-coded wiring system and demonstrates a practical application where you're adding an air conditioner while upgrading a single-stage furnace to two-stage operation. The Fast-Stat Model 5000 is compatible with most 24-volt AC heating and cooling systems, making it a versatile tool for HVAC technicians looking to streamline their installation process. Perfect for contractors who want to reduce wiring complexity and save time on system upgrades. Learn more at https://fast-stat.com or purchase online at https://hvacrschool.com/fast-stat Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

ylWJoMeI3po | 20 Aug 2025

In the Part 2 of VRV Data Analysis Class, Roman Baugh dives deep into the advanced field settings and control parameters that make Daikin's Variable Refrigerant Volume (VRV) systems so versatile and efficient. What You'll Learn: Field Settings & Service Tools Complete overview of all field settings available for VRV indoor units How to use Mode 1 settings to monitor system parameters without making changes Understanding Mode 2 settings for making actual system adjustments Service manual navigation and finding critical component locations VRT Technology Deep Dive What VRT (Variable Refrigerant Temperature) really means and why it matters How VRT automatically adjusts evaporator saturation temperature based on outdoor conditions The relationship between saturation, temperature and compressor speed for energy efficiency When and why to turn OFF VRT for better humidity control Humidity Control Solutions Why VRT can cause humidity complaints in Florida and similar climates The science behind dew point and moisture removal How to manually override VRT settings to improve latent capacity Practical troubleshooting for "it doesn't remove humidity" complaints Advanced System Control Understanding compressor step control (up to 170 different speeds!) Ethernet addressing and group addressing for centralized control Target condensing temperature (TCE) adjustments for heating mode How multiple compressors work together in larger tonnage units Data Analysis & Diagnostics Reading and interpreting service checker data Using piping diagrams with temperature sensor locations Tracking compressor runtime hours for maintenance planning Correlating field measurements with system performance Key Takeaways: Energy vs. Comfort Trade-offs: Learn when to sacrifice some energy efficiency for better humidity control Practical Problem Solving: Real-world scenarios where manual overrides solve customer complaints System Optimization: How to use advanced settings to fine-tune system performance Professional Diagnostics: Advanced techniques for troubleshooting complex VRV issues Perfect for HVAC technicians working with Daikin VRV systems who want to move beyond basic service calls and truly understand the sophisticated control strategies that make these systems so effective. The 3 Pillars of Daikin Service Checker Analysis: https://youtu.be/mpDvDaOEdNA Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

q6ZqwYKHMYE | 18 Aug 2025

Join Ty and Ash as they demonstrate the proper use of WETRAG HEATSHIELD and WETRAG Heat-Blocking Putty from Refrigeration Technologies when brazing near sensitive components like evaporator coils, aluminum parts, and electrical connections. In this hands-on tutorial, they show how to protect delicate HVAC components using WETRAG heat blocking putty and HEATSHIELD during torch work. What You'll Learn: How to properly apply wet rag heat blocking putty around sensitive components Correct placement and use of heat shields during brazing operations Why aluminum components need extra protection compared to copper Safe torch techniques and flame positioning for effective brazing How these products protect against accidental damage from torch flames Easy cleanup methods and product reusability Products Demonstrated: WETRAG Heat Blocking Putty (reusable) Viper HEATSHIELDS (flexible, long-lasting protection) Proper torch safety equipment and techniques This video is perfect for HVAC technicians, apprentices, and anyone working with torches around sensitive equipment. See firsthand how these protection methods can save you from costly mistakes and keep your work area safe. Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/ or the HVAC School Mobile App on the Google Play Store (https://hvacrschool.com/play-store) or App Store (https://hvacrschool.com/app-store).

bbgziEvklhI | 15 Aug 2025