Channels lising page

All videos archived of Matthias Wandel

bQmQURhFCNc | 20 Dec 2025

The kids wanted doll beds, I wanted them to have drawers to put their stuff away. I found a way to address both with one project. Lots more about drawers at: https://woodgears.ca/drawers

HvNXjTfrVM4 | 17 Nov 2025

Playing around with making a simple drawer box, using some vaery sturdy cardboard. Doweling sleeves (drill bushings) USA: https://www.amazon.com/dp/B0FQ473DG3 CA: https://www.amazon.ca/dp/B0FQ473DG3

AEUPbJZBFM0 | 12 Nov 2025

I had to make several picture frames, so a good chance to hone the process and then make a video. This time I used a big router bit to make most of the molding shape. Plans for my tilting router lift: https://woodgears.ca/router_lift/plans_t/index.html

R1z31pLffR8 | 24 Sep 2025

Flexispot E2 (the basic one that I used) https://bit.ly/46J0UbM Flexispot E7 Pro USA: https://bit.ly/46qVdz0 Canada: https://bit.ly/46q06Ij Keywords: FlexiSpot, E7 Pro Premium Standing Desk The CNC on the table is the Carvera Air from Makera: https://makerainc.sjv.io/nXxLd6 $100 cupon code for Makera or Makera air: matthias100 More on wooden drawers at: https://woodgears.ca/drawers

hlvHNgOD__Y | 18 Sep 2025

PCBWay Custom PCB manufacturing: https://pcbway.com/g/9wYeGG PCBWay also does custom machining and 3D printing Carvera Air from Makera: https://makerainc.sjv.io/nXxLd6 A very capable machine, way overkill for milling PCBs. $100 cupon code for Makera or Makera air: matthias100 My Gerber to G-code python script https://github.com/Matthias-Wandel/Gerber2nc

rMeshyaFoDs | 10 Sep 2025

Carvera Air from Makera (affiliate link): https://makerainc.sjv.io/nXxLd6 $100 cupon code for Makera or Makera air: matthias100 I figured I'd learn another CAD program to make proper tool paths for the Makera Air CNC to mill stuff out. The learning curve is steep, especially with FreeCCAD, and if CNC is only used occasionally, may require re-learning every time its used. Aborting the Makera air too often can get it into a funny state. That said, the Makera is very solidly built and works well.

9luLIPB1hxU | 25 Aug 2025

Amazon listing for packs of 12 of these dowel sleeves (drill bushings): Canada: https://www.amazon.ca/dp/B0FF99QMMP USA: Out of stock https://www.amazon.com/dp/B0FF99QMMP The ones I showed are slightly yellowed from hardening. The hardening treatment has since been improved to not result in yellowing and slightly greater hardness.

GuzC8QmhXNU | 26 Jun 2025

Examining and dissecting it to see how various engineering challenges are involved. Use promo code: WOODGEARS to get 10% off any purchase This standing desk: https://thestandingdesk.com/shop/kloud-desk/ More standing desks https://thestandingdesk.com/

I0q68a0ZaMM | 30 May 2025

"helping hands" gadgets for soldering are very handy, but they are also hard to adjust and flimsy. So I built a better one, based on dial indicator holders. Dial indicator arm: Without magnet: https://amzn.to/3FjmMRk With magnet: https://amzn.to/3T5VzEF Scribing calipers https://amzn.to/3FGEpdI

8kwCHrqtchI | 15 May 2025

Building a toy castle set for our youngest, very much inspired by Ostheimer castle sets. Ostheimer makes some nice wooden toys, but they are very expensive. More wooden toy projects: https://woodgears.ca/toys/ More about building the knight, dragon and princess: https://youtu.be/D5G8nmWIMlg?si=9QZVl6SW4DTcfIrf&t=287

nGBGPiqzeNk | 09 May 2025

I copied a free energy spring engine, and actually got it running. No video manipulation, no hidden wires! These free energy spring engines seem to be all the rage lately, so I thought I'd jump in on the trend. But watch to the end.

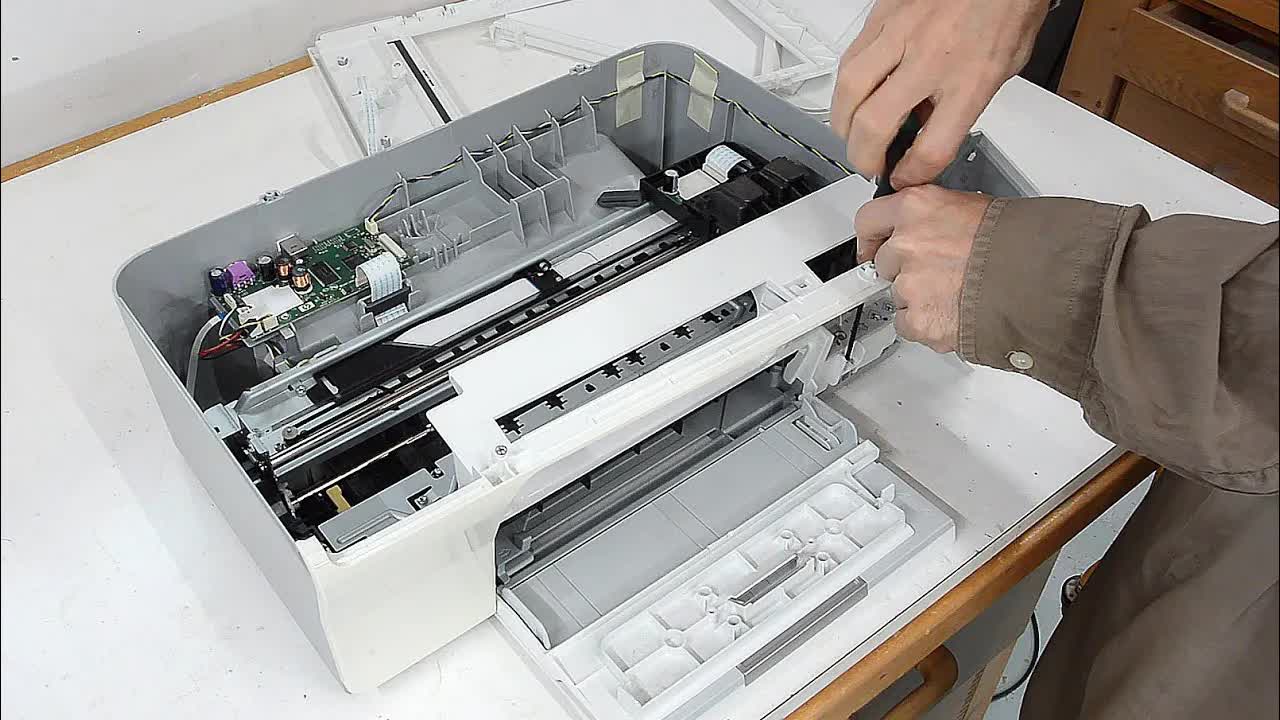

CwBs31oR7Ak | 06 Apr 2025

Repairing another curb find. Though realizing afterwards how little these costs, justifying the effort was questionable. But the kids loved it. I used my screw advance box joint jig for the joinery: http://woodgears.ca/box_joint/jig.html Plans for it here: https://woodgears.ca/box_joint/plans/index.html

ndvRsQx3xBw | 31 Mar 2025

Setting up a test apparatus to characterize a 3d printed blower impeller, measuring air flow, pressures and power consumption, comparing running it with the blades facing forwards or backwards. Thanks to Doug Kremer for sending me this very nicely made 3d printed impeller.

IPHJRxMe_Vs | 22 Feb 2025

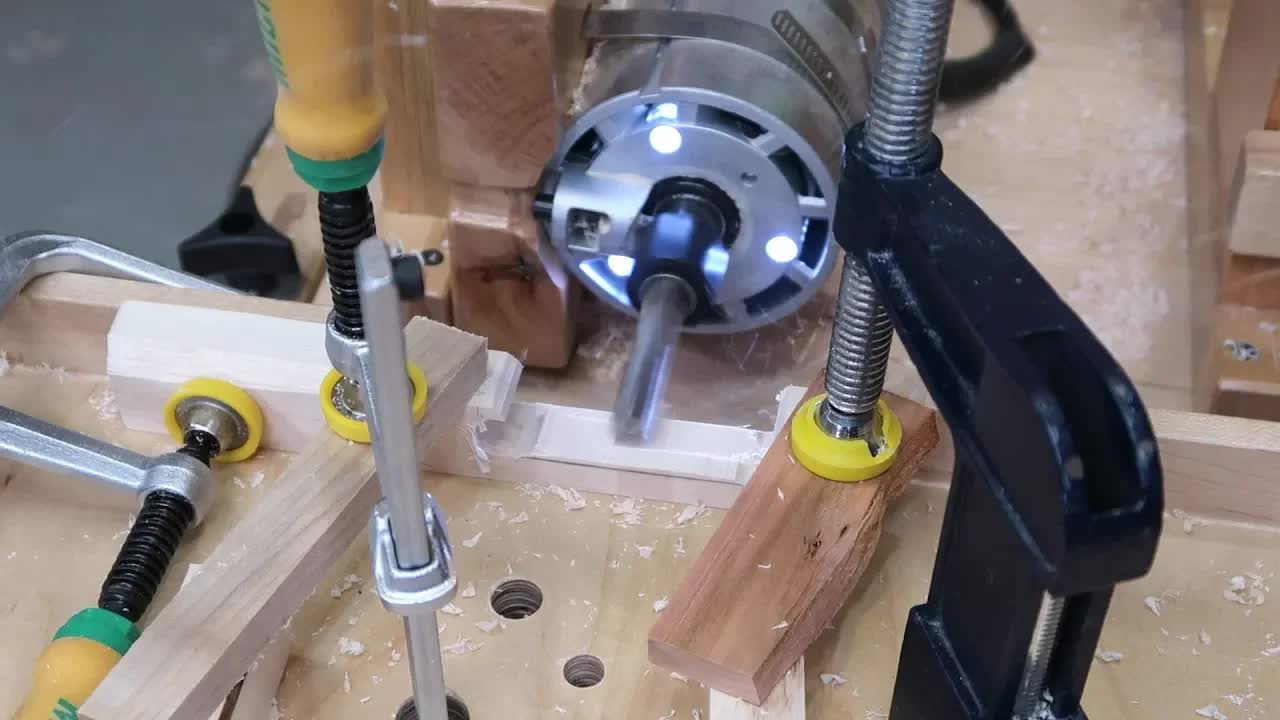

I built this machine primarily as a milling machine last year. Its not quite stiff enough to be a good milling machine, but I love using it as a drill press with XY table. So making improvements to the mechanism for setting the drill height, as well as making a better rack and pinion plunge mechanism using a lantern gear

ifcNpmJw0Tw | 11 Feb 2025

Its always easier to cut side grain, and if the router bit is drilling (plunging) the end is cutting side grain, which should be an easier operation than dragging it sideways through the material. So I set up my CNC router to mill that way to try it out. My gear program: https://woodgears.ca/gear DMM servos: https://dmm-tech.com/

wMi0TJx-7ks | 30 Jan 2025

Having obtained a bunch of linear rails, ball screws and servo motors, I figured I might as well try to build a CNC router out of it. I'm not sold on CNC, but having the parts, I might as well try to build one and see how it goes.

TZjBL1mqGns | 27 Dec 2024

I used to wonder why so many new dressers suck. But its atually deliberate to prvenet tip-over. In the United States, there is the STURDY act that mandates dressers must not tip over if a toddler opens all drawers and climbs up the front. In Canada, we don't have this act, but I think manufacturers are afraid of liability. And so the actual ability of storing stuff (which is what dressers are for) is greatly compromised.

D5G8nmWIMlg | 18 Dec 2024

How to update your software so it runs on the latest version of windows without having to install the dot-net 3.5 framework. https://woodgears.ca/gear/ https://woodgears.ca/bigprint/

sASwadHr11M | 05 Dec 2024

A very simple 3-piece pyramid burr puzzle that is surprisingly counter intuitive to reassemble. Making this puzzles so it fits properly requires precision. First just gluing it straight up, then another reinforced with dowels, with the dowel holes precision drilled on my homemade milling machine. Drawings of the puzzle here: https://woodgears.ca/puzzles/pyramid.html

YITDLmRWnqM | 02 Dec 2024

I needed a short brad point drill bit, so I started with a regular drill bit and ground a brad point on it with a dremel tool and jig to guide the cutting disk precisely.

zyqUn-rMUJk | 29 Nov 2024

Testing how well the glue sticks to wood that's been lying around for a while vs. freshly sanded or planed down a bit. I expected this to make much more difference than it did, even with some non-ideal surfaces. Lots more glue testing related work at the bottom of this page: https://woodgears.ca/joint_strength/index.html

TwZNbXG_0fE | 21 Nov 2024

A presentation I gave at "Holzwerken live" in Hamm, Germany on November 9 2024, about why I don't use a CNC. This is the english version. German version https://youtu.be/e0-Xc-B2mkU

e0-Xc-B2mkU | 21 Nov 2024

German language video. English version: https://youtu.be/TwZNbXG_0fE A presentation I gave at "Holzwerken live" in Hamm, Germany on November 9 2024, about why I don't use a CNC.

2MMW_-KWS7Q | 18 Nov 2024

FlexiSpot Amazon Black Friday, Up to 70% off. Also 20 randomly selected buyers will get their purchase refunded (free orders) on November 29 an December 2ndOn November 21, 28, and December 2nd the first 20 buyers of a standing desk will receivea free drawer Also On November 28 and December 2, the first 30 buyers of a standing desk will receive a free keyboard trayThe E6 desk in this video: https://amzn.to/3NVBdvC US Amazon Site:https://amzn.to/3YxJNWgCanada Amazon Site: https://amzn.to/48Cjlzh

JpqdsykZjHA | 28 Oct 2024

Making another rack to hold cardboard boxes, but not having enough boxes, I also made some drawers to go on it. These looked so nice, I ended up gluing drawer fronts onto the cardboard boxes to make them look like drawers and easier to pull out.

o-lUO6Qv8YI | 21 Oct 2024

Experimenting with how well drywall screws screwed straight into steel hold. It turns out, surprisingly well, even if the pilot hole is large enough that there is only minimal thread penetration into the steel

rIXORigQksk | 28 Sep 2024

Building a workbench for the kids. I started wanting to build something quick and rough, but then it turned out much nicer than I had planned on, almost too good for banging on. The structure of this one is inspired by my kids craft table build: https://youtu.be/xT1mRvHZlQ8

vzs6Q9sktjc | 12 Sep 2024

Using a router mounted on my metal lathe, and working out a gear combination to make a big wooden screw with an 8 mm thread pitch. My lathe thread gear calculator: https://github.com/Matthias-Wandel/lathe-thread-gears

7zqkpfFkU3s | 10 Sep 2024

Making a tray to go to the left of the slide on my lathe to catch chips and shavings, so they don't end up on the ways or the lead screw. This involved a bit of sheet metal work, using a vise instead of a metal brake to make the bends.

rYmYF5I0ww4 | 04 Sep 2024

Making a dresser is a lot of work. But if you buy a nice one instead, you spend a lot of money and get something that might only be able to store half as much for the same size dresser. The other dresser on my website: https://woodgears.ca/dresser/7-drawer.html

ahu-6kZyEB8 | 22 Aug 2024

An update on Amogla camp, and various patch jobs, as there is too little time to do a proper repair for most of these. Playlist: https://www.youtube.com/watch?v=JydDsMPn-9E&list=PLSnvVtM4lBIWYpkAqQ2qvydElONC3NIwu More about the camp on my website: http://woodgears.ca/amogla

edEfT34AXio | 04 Aug 2024

Experimenting with end to end wood joinery to make boards longer. I tried a 15 degree V-joint. Though not nearly as strong as solid material without a joint, it does much better than a finger joint I can make. Tapered finger joints would probably do better but I don’t have the tooltip g to make these.

lrLWkvowqhI | 27 Jul 2024

Rachel wanted to build a bookcase, so we built one together. Nice to have help. Filming with help doesn't quite go as planned as filming alone. The design of this one is very similar to one I built two years earlier: https://youtu.be/88XLFQYnIik

BQoFMSj4gi4 | 28 May 2024

Milling a metal block in to a dowel jig for 3/8-inch dowels. Essentially a 3/8-inch drill guide with four holes, to be screwed to a block of wood which is then clamped to the workpiece. This will simplify some of the dowel joinery I often make. This is my first project using my homemade milling machine contraption. Far from perfect, but much better than trying to do this with a drill press.

1XGACnLDEps | 22 May 2024

A catapult without springs or weights, powered by kids stomping on it. Have been able to shoot small potatoes over 45 meters or 150 feet with it. Much further than a comparable size trebuchet ever would! Safe? Well, without springs or weights to power it, it can never go off by accident. But any contraption that throws something has some inherent risk to it.

3tqNmV8KaZU | 19 May 2024

Testing some scale model sawhorses for strength using my strength testing machine. Craftwrigth's workshop https://youtube.com/@Craftswright Sawhorse video: https://www.youtube.com/watch?v=LJucrdhjIZk My sawhorses woodgears.ca/sawhorse Video: https://www.youtube.com/watch?v=DtizUSUgUG4

mJqtx0jKxbU | 30 Apr 2024

Building something between a drill press and milling machine, using lots of Chinese parts of various quality bought online. Gear program: https://woodgears.ca/gear BigPrint program https://woodgears.ca/bigprint

u3odx-77Ymc | 24 Apr 2024

Taking a Flexispot E2 standing desk and modifying it to be less wide and less deep to fit a small desk top in a tight space. Sponsored by FlexiSpot FlexiSpot C7 Premium Ergonomic Chair Use code ‘C730’ for $30 off on $400+ purchase on C7 Chair USA: https://bit.ly/3R1cZky Canada: https://bit.ly/3tkFodx

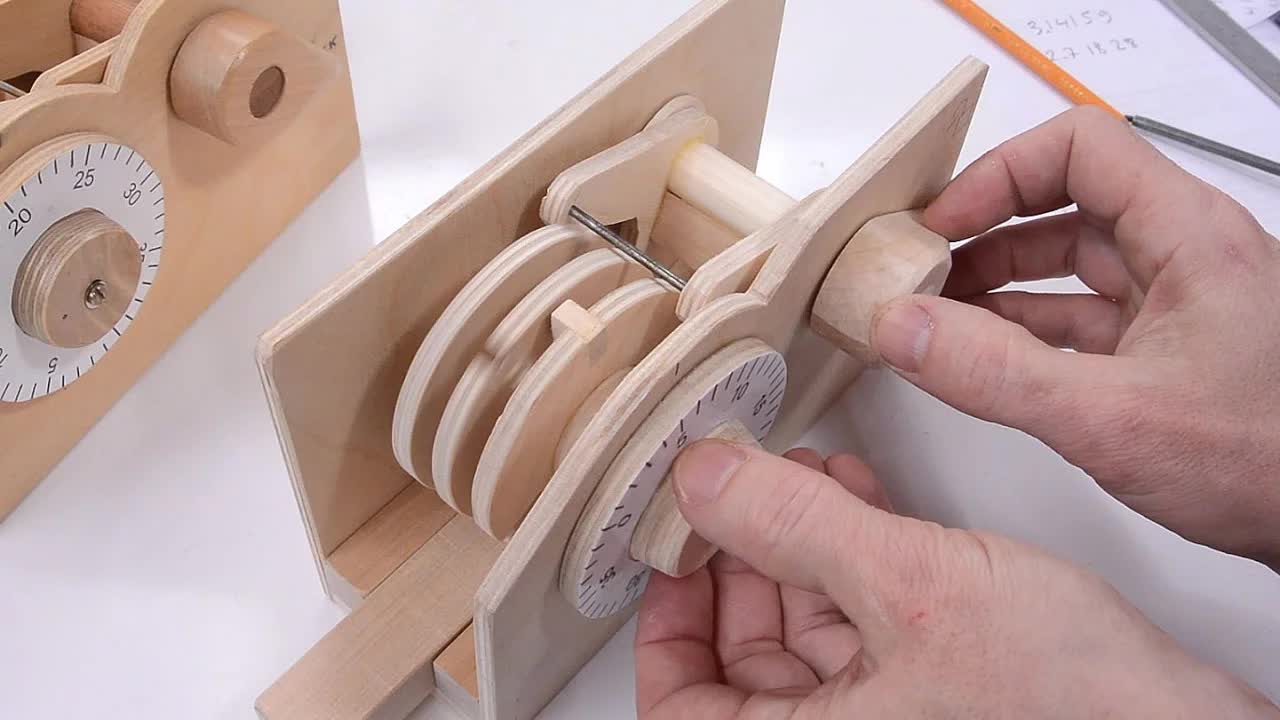

sYw7OfeC1b8 | 15 Mar 2024

The threading table for my Vevor metal lathe was very inaccurate, so I set about to come up with a much more accurate thread cutting table. With five gears that can be swapped out, It's possible to approximate any arbitrary thread pitch with surprising accuracy. I also tried making some wooden gears to explore the possibility of just making custom gears for it. My gear program: https://woodgears.ca/gear Vevor mini lathe: https://s.vevor.com/bfQKTC I have uploaded my Python script to github: https://github.com/Matthias-Wandel/lathe-thread-gears

DqLrGTTWKlM | 07 Mar 2024

Wanting to measure the index of refraction of a lens, I made a curvature gauge. Making this required drilling some holes very precisely, and an X-Y table was very handy for this task.

_tlhOBysXOE | 31 Jan 2024

How I accidentally compromised my computer as a result of a social engineering attach, resulting in a session hijack attack on my main YouTube channel, timing of it, analysis, and recovery. My initial very short video about the hack: https://youtu.be/Bzys4SSNqhU

74H-BtLwRgU | 26 Jan 2024

We have a lot of these identical cardboard boxes from buying blueberries over the years. They are very handy for storing stuff in, so I made a rack to hold 24 of those. More storage solutions: http://woodgears.ca/storage

xT1mRvHZlQ8 | 21 Jan 2024

Building a table for the kids to do their crafts on, and a different way of attaching the table legs, without an "apron" around it. Simpler and leaves more room under the table, but makes it less stiff. But the hardwood trim helps to stiffen up the table top. More table builds: http://woodgears.ca/table/

-wEshvhpLWU | 16 Jan 2024

Reflecting on my experience with Vevor, and how they are quite ok with honest reviews pointing out some of their flaws, and how that, surprisingly, may be a good marketing strategy. So far have two Vevor produgts. The lathe -- which after some tweaking, I'm happy with, and the milling table, which I bought. The lead screws on it are crap, but I'm actually thinking about buying a second one.

_2KEGriaszE | 09 Jan 2024

Trying to get the wobble out of the lead screw advance on my Vevor milling table. This milling table doesn't cost a lot, but if you buy one, you are buying a project giving it the care and attention to detail that is lacking in the design and manufacture of this product.

YO0jkLHmQow | 03 Jan 2024

Adding a drawer to the stand for my mini lathe so I can put it away easily together with the tools. I have already accumulated a few extra bits for the lathe, but hopefully I will be able to keep the accessories to a quantity that fits in the drawer.

n-YAWpAmioQ | 23 Dec 2023

An experiment that had to be done -- how far will a chuck key fly if left in the metal lathe chuck. Reminds me of my unsuccessful experiment of getting a shirt sucked into the table saw. https://www.youtube.com/watch?v=UeQzIzj3j_Q More about the metal lathe: https://youtu.be/oxQTtV91KIw Leaving the chuck key makes for more viewer enagement: https://youtu.be/goD9NTTflpI

xYwTWI4SXUQ | 22 Nov 2023

Testing how much weight a FlexiSpot E8 standing desk can lift. Surprisingly much, it turns out, and I used it as a gantry crane too! Not a recommended use of standing desk frames. FlexiSpot Amazon Black Friday Deals, up to 70% off For Black Friday and Cyber Monday (Nov 24 and 27), FlexiSpot will randomly select some customer orders and give full refunds (free product) USA: https://amzn.to/3QszqPi Canada: https://amzn.to/47ny6UB #blackfriday #amazon #standingdesk #flexispot

0-6RctbVxFo | 03 Nov 2023

A very simple platform that allows for easy aiming of a camera or phone, based on the idea of a ball and socket joint. If you want plans, see the dimensions for it near the end of the video.

_Vj3i2SurdU | 28 Oct 2023

Modifying my strength testing machine for pull (tensile) tests. Then using the machine to test how well wood screws hold in wood against pull out. Also testing head pull through force and effect of pilot hole size on how well the screw holds.

a_hX2JcwHBE | 13 Oct 2023

Building a wooden enclosure for a simple micro controller project. The project just changes the color of the built in light as a subtle reminder of time for counseling sessions for my brother in law. This is inspired by https://timeqube.com (no affiliation). My other YouTube channel: https://www.youtube.com/channel/UC3_AWXcf2K3l9ILVuQe-XwQ

K_1li4SpFmk | 05 Oct 2023

More testing on Marius's edge clamps vs. the expensive Bessey edge clamps. Testing force applied with a jig and a load cell, friction limits of the cams, and practicality of edge clamps for some applications.

6EqJpt3axCM | 26 Sep 2023

Standing desks present a problem for adding drawers. The mechanism limits how deep the drawers can be. I came up with a drawer with a second set of slides further down so that the drawer can be pulled out most of the way, enabling maximum utility for the depth available. ------------------------------------------------------------- STANDING DESK AFFILIATE LINKS E7Pro standing desk (the one in my workshop) https://bit.ly/MatthiasUS https://bit.ly/MatthiasCAN More economic standing desks (desks or frame only) for smaller desks: bit.ly/matthias_fs Or buy on Amazon. USA: https://amzn.to/3EGPdEC Canada: https://bit.ly/3zv7ceQ Buy the whole desk: https://amzn.to/3MeADJG ------------------------------------------- HOMEMADE MACHINES Screw advance box joint jig: https://woodgears.ca/box_joint/jig.html Tilting router lift: https://woodgears.ca/router_lift Edge belt sander: https://woodgears.ca/belt_sander/ 26" bandsaw https://woodgears.ca/big_bandsaw/26in.html

GgYXvgqaVuo | 09 Sep 2023

Marius Hornberger wanted to know what type of joinery was best for his edge clamps, so he sent some samples for me to test on my joint strength tester. But it wasn't as straightforward as we had anticipated.

QQOWzAxfmsc | 23 Aug 2023

I bought one of those expensive Bessey edge clamps. A very solidly built clamp, but just as awkward to use as my f-clamp and wedge type hack. But in a pull off test in my strength testing machine, it held on impressively well.

gtbntjmzZ9U | 18 Jul 2023

Investigating how separately motorized standing desk legs stay in sync even with very uneven loads, then dissecting a 3-segment standing desk leg to figure out how it actually works. E7Pro standing desk: https://woodgears.ca/dr/E7Pro More economic standing desks (desks or frame only) for smaller desks: https://woodgears.ca/dr/FlexiSpot Or buy on Amazon. (E7Pro is not currently on Amazon) USA: https://amzn.to/3zfBHoR Canada: https://amzn.to/3lNGvyL

iXScBNZVJ28 | 30 May 2023

Joining pieces of wood that aren't quite straight, using bamboo skewers to reinforce and force alignment. This to build the top for a standing desk frame. Ordering the frame without the top is usually about $70 USD less. Standing desk frame (affiliate link USA only) https://bit.ly/3zv7ceQ Same frame, with desk top https://amzn.to/3MeADJG More standing desks from Flexispot: USA: https://amzn.to/3zfBHoR Canada: https://amzn.to/3lNGvyL You can also go to flexispot.com if the affiliate links show out of stock.

ZRXyv5LLoOU | 12 May 2023

Fixing broken legs on a pedestal table. This style of table is kind of a faulty design and often breaks, where the legs meet the column, and the curved legs themselves often split apart along the wood grain

Slq0aHXEacw | 05 May 2023

Fixing a dresser I picked up off the curb because it was made of solid wood, not particle board. The drawers had mostly come apart, and it was missing one. I also disassembled the carcas so I could glue the joinery, instead of relying just on knock-down fasteners. So much less work to fix this than to make a new one.

qrUJcxlnhVA | 17 Apr 2023

Using a swing-arm style architect lamp for a nightstand. The lamp needed to be raised up a bit more, so instead of using the flimsy base it comes with, I made a pedestal base that mounts on the nightstand to bring it to a good height.

_riUXuRC7yc | 11 Mar 2023

Making some drawers for a small desk. I figured having keyboard in one of the drawers would be very useful, but I wanted the drawer to also be usable as a drawer, so its a drawer with a keyboard in it.

AauvMlNt6ds | 03 Mar 2023

A contraption Mac Sheldon asked me to come up with to help assemble dust collector hoses for pahtorouters. With thousands of hoses to do, simplifying one step is worth the trouble. This is for the metal pantorouters that Mac Sheldon sells at: https://pantorouter.com

s1ymBLSmYv4 | 14 Feb 2023

Making a replacement broom stick out of hardwood. First making a 7/8" (22 mm)dowel, then a thread on the end. Hand filed the thread, that took 15 minutes, less time than figuring out how to set up a machine to do it.

08JogOoO6lQ | 19 Dec 2022

Talking about woodworking videos and screwing up. Yes, I screw up more than I used to. But more than that, I show more screw-ups than I used to because I think they make the videos more entertaining. Going over the dresser I built and showing stuff I screwed up. This relating to the dresser I finished recently: https://youtu.be/OE4JhvynKzw

_-JeEMuuZqU | 17 Nov 2022

Building a small desk for our 7-year old, and a worktable for me for electronics, both nearly the same design. But lots of little screw-ups during the build. and a cameo appearance by a real camera man from CBC!

W9T64bny9gc | 25 Oct 2022

A really quick table build on a Saturday, for my brother in law. I didn't even take the time to set up a camera, so I just used images from timelapses I captured with my imgcomp program. This worked surprisingly well. https://github.com/Matthias-Wandel/imgcomp

C2DZuVx0G7Y | 17 Oct 2022

A simple jig that's easy to make so it lines up miter joints properly with dowels. Another picture frame build: http://woodgears.ca/frame/picture_frame.html More about doweling: http://woodgears.ca/frame/dowel.html

_D8skTwdFtU | 12 Oct 2022

Sponsored by PCBWay.com. $5 off your 1st order with this link: https://www.pcbway.com/setinvite.aspx?inviteid=599997 PCBWay.com does 3d printing, CNC machining and PCBs and PCB assemblies. Iterating through a design for a segmented Knapp-joint template for the pantorouter. This is work I was doing for Mac Sheldon (pantorouter.com). He plans on offering knapp joint templates for sale in a few months time. Getting production tooling made for injection molding these takes time. Previous knapp joint template work: https://woodgears.ca/box/knapp.html

IpdEhi0FgKg | 22 Sep 2022

Testing some samples of plywood, Baltic birch (Russian birch), MDF, particle board and OSB. Also testing these against pine and birch. More about my wood strength testing machine at: http://woodgears.ca/wood_strength/

XyLos3M3LWw | 16 Sep 2022

A tray with a flip up handle that has a wooden latch to keep it up. http://woodgears.ca/kitchen/ramekin_tray.html I built this in 2014, uploaded the video, but realized too late it was a low res test render, and re-uploading right away jinxes the algorithm. Re-uploaded a full res version in 2016, but some time in late 2021, YoTube managed to screw up the audio sync on it. So this was an opportunity to re-edit it, 8 minutes down to 5, and publish it again.

CUPkudnw9X4 | 09 Sep 2022

Looking into using 5 mm thick bamboo shish kabob skewers as dowels, testing strength and how well they hold glued into a hole. These don't cost very much so are a good alternative to using dowels. More about using dowels at: http://woodgears.ca/dowel

KYcrlcYAPW4 | 14 Aug 2022

Fixing the floor and railing of a kid's wagon. I also made a "trailer hitch" for it so another wagon can be hooked to the back of it to make a train. Previous repair of such a wagon: http://woodgears.ca/toys/wagon.html

_CsV6LxhtTk | 08 Aug 2022

I built this air raid siren ten years ago. Looking at the old video, I realized I could edit that much better now. This version is only half as long without skipping much! Article about the siren build: http://woodgears.ca/siren 2012 building the siren: https://youtu.be/XAfvOjdZpkg 2012 testing the siren: https://youtu.be/2Tr6hCZAVhI

KvJCCamOK1Y | 26 Jul 2022

Adding a drawer to my little "lab table" that I built recently. I used wooden drawer slides for the simplicity and cost, but with wax and mineral oil was able to make the hardwood on hardwood slide really easily

w0llTMDDgn0 | 17 Jul 2022

Using my vacuum patio stone lifter contraption to lift all the patio stones, re-level the sand and gravel, take out weeds and add additional barrier to weeds, then new sand in the cracks. Hopefully this will stay weed free without pesticides for a few years.

qdpY23nDQgE | 12 Jul 2022

Dealing with a wasp nest that I can't directly get at. This originally shot and published in 2014, but re-edited to be much shorter, like I have done with #shorts, but using regular format, because that appears to work much better for me. Previous video on that topic: https://youtu.be/OM4Nku2qAiI Earlier video on that topic (from 2011) https://youtu.be/Gk52XA4rFpw

OdxkP7tFUzk | 23 Jun 2022

Analyzing sources of noise and vibration on my homemade jointer. The shelix head made it much quieter, but without the cutter head dominating the noise, there are a lot of other noises to chase. More about my homemade jointer: http://woodgears.ca/jointer/homemade.html

rehZ8SqszAk | 01 Jun 2022

Upgrading my 12" jointer to a Shelix head and testing it. Cut quality is improved, but there's more to it than that. The carbide shelix head is not a clear win. More about my homemade jointer: http://woodgears.ca/jointer/homemade.html

-h5b57ZxQQI | 19 May 2022

Nearly all window air conditioners are made for vertically sliding windows. I made a new window panel to fit a window air conditioner into a casement window. Testing the window air conditioner: https://youtu.be/zcxeokD2s6k Amazon purchase link: https://amzn.to/3NnDD3y Discount code: 50AC002 (Valid thu May 22) Also available on Dreo's website: https://dreo.com/products/dreo-arctic-one

MdX4zZGwyjg | 11 May 2022

Demonstrating how I use my BigPrint program to make 1:1 tempaltes. I do this every time I have a CAD model of something and want to build it in the workshop. You can buy BigPrint here: http://woodgears.ca/bigprint

nz6jF-GsRqk | 14 Mar 2022

Using two simple squares as fences to use a handheld circular saw to cut a dado joint in wood. The ends of the fences are pushed against a thickess of thee wood to be fit into the dado, which sets the correct spaces for the skillsaw to cut the dado. #shorts

sOoaIF2xr7Q | 28 Feb 2022

The lengths a mouse will go to to jump for food! This video is a shorts version of a video I made two years ago that never gained much traction. I think the original video was too long for what it is. More about the origin of this mouse video http://woodgears.ca/farm/circus_mouse.html Longer version of the mouse video: https://youtu.be/z4xZpm5n214 #shorts

3Ve94qs-R80 | 30 Jan 2022

Testing different species of wood for strength against splitting. But after that I found a flaw in my procedure. But the data still reveals some interesting things. Spreadsheet here: http://woodgears.ca/wood_strength

_hWboT47RyU | 28 Jan 2022

Filmed on a visit to John Heisz shop in 2016, we got to talking about folding and unfolding bandsaw blades. I proceeded to show my way of folding and "unfolding" the blades, much to John's humor! Good times!

UwGAzc96Wa4 | 17 Jan 2022

A quick and simple trick to hide the occasional embarrassing gap in wood joints. This is a re-edit to short from a video I originally shot in 2015, so I figure after 7 years a re-hash is ok. Also formatted to be nearly square instead of mostly vertical, seeing that a lot of folks also watch my shorts on regular YouTube. Not a great thumbail, but uploading thumbnails to YouTube appears broken today. #shorts

MBfzDEgfA0I | 17 Dec 2021

Using my wood strength testing machine to break many different species of wood to figure out which ones are the strongest, stiffest, hardest. There is so much more that could be explored this way! http://woodgears.ca/wood_strength

lpjf5KoqpRQ | 30 Nov 2021

Using my joint strength tester to break lots of pieces of the same kinds of wood, exploring consistency and how well it bends if heated or soaked in water. No one answer, but steaming wood may not be the best way for bending, depending on species. 1080p version. Accidentally uploaded the 480p version the first time.

hxR-dexHiI4 | 17 Nov 2021

Building a computer controlled wood and joint strength testing machine. Sort of like my own Instron tester. Using a stepper motor, wooden gears and a threaded rod for the ram, and bathroom scale load cells to measure the force.

12O_ZbOWxak | 26 Oct 2021

I needed something to hang a picture on a high hook where I couldn't use a ladder. Then realized I had *almost* the perfect gadget already. #shorts This idea made for a very short video and the vertical format worked well for where I filmed it, so might as well try out these dreadful shorts!

gt38-y7bm_k | 17 Oct 2021

Adding sheet metal roofing to my shed, with a homemade ridge cap, also using the sheet metal as siding, wrapping it around the corners by bending it with an improvised sheet metal brake. http://woodgears.ca/shed

AbcO7EjfrUA | 10 Oct 2021

Time to prepare the site for the shed, place the walls and screw them together. The shed is like a plywood box and very rigid against twist and warping. If the foundations give out, it will be easy to straighten it back up. More about sheds: http://woodgears.ca/shed

61ceMgGZTnQ | 27 Sep 2021

Reduced my 44 minute build series from 5 years ago into one shorter video. This has most of the info from the longer series. Though if you want to build it, I also recommend watching the longer series: https://www.youtube.com/watch?v=4tdSaE663AU&list=PLSnvVtM4lBIUFfaqrjFXs4kxIq8JkWpNI Plans: http://woodgears.ca/belt_sander/plans More about this belt sander: http://woodgears.ca/belt_sander/

5jki5s3NF1g | 24 Sep 2021

I built this belt sander 5 years ago, talking about minor tweaks I have made to it in that time, and checking how it's doing. More about the belt sander: http://woodgears.ca/belt_sander Plans for this belt sander: http://woodgears.ca/belt_sander/plans

zr1PP8RcaNY | 07 Sep 2021

I started this out wanting it to be done before I started and not making a video. But being in a hurry I screwed up a lot. When I got back to it a few days later, I thought talking about all the screw-ups might be interesting. More table builds: http://woodgears.ca/table/ More articles where I measure things, often using a raspberry pi: http://woodgears.ca/physics/index.html

8gqBatgAUhY | 03 Sep 2021

Second channel: https://www.youtube.com/channel/UC3_AWXcf2K3l9ILVuQe-XwQ This is just a talky vlogy style videos. I usually put videos like that on my second channel, but it appears not everyone knows about my second channel, so I'm putting it on my main channel. A guy stopped on road while I was mowing, didn't know about second channel. So just in case you don't know about my second channel - I have a second channel. I do have a second channel, in case you don't know. It's called "matthias random stuff". Its Random stuff really. Kind of inspired by technology connections. New videos on that have been doing about as well as on my main channel, even though it's only 110k subs vs 1.6 million subs. Of course, my main channel is way down from years ago. Sometimes trivial videos like my fan balancing, or cleaning a paint brush, and sometimes those do well. I also like to play around with electronics, raspberry pi computers, do experiments and measure stuff, but those kinds of videos usually don't do as well. So going forward, I'll put woodworking stuff on my main channel, and non-woodworking stuff on my random stuff channel. Sponsored video: Ecoflow Not thru an agency, which is nice! More flexibility, no dictated talking points. Doesn't feel like I'm interacting with a marketing department. Not like skillshare, vpn, mattresses, razors, audible and the likes. Have been making the website more mobile friendly. Been playing with ads on my website lately. But mostly the ads I get are for the 14000 plans teds woodworking scam. Or ads for some gadget that cuts your power bill by 90% if you plug it in. kind of discouraging. But I don't give google a lot of hints for things I might want, spread over multiple browsers, switched to Bing cause I don't trust google's results biases and data harvesting, and often search incognito. I have to say, google works better though, so I sometimes search again in google if I can't find what I'm looking for. What ads are you seeing? Partnered with Jellysmack for my woodgears.ca facebook page. They take my videos from YouTube and edit them down a fair bit from the original, for casual viewing. I find I skip forward thru videos a lot. So short attention span, fast paced videos do have their place. Maybe we are all getting ticktockified Veritassium video about clickbait. After that video I suddenly saw a whole lot more clickbaity titles in my subscription feed. Clickbait is an advantage, yes. But is it when everything is clikcbait? What about long term reputational harm? Maybe there is just too much stuff out there to suck our attention, so we all have to get better at sucking people's attention, everyone's time is fully sucked up. It used to be that technology was a productivity tool but those days are long gone! Feed the algorithm - the end goal of the algorithm is that you watch more. Subscribing or commenting matter a lot less. So if you want to support me, just watch more, or if you don't feel like it, maybe leave a video running after this one on mute while you do something useful?

qLLVTdBKKW4 | 30 Aug 2021

My bandsaw on a dolly sawmill using the same 20" bandsaw: Sawmilling with the 20" bandsaw: https://woodgears.ca/big_bandsaw/sawmilling.html More cutting up logs on a bandsaw: https://woodgears.ca/reclaim_lumber/bandsaw_log.html

CPv4IUSyIPk | 27 Aug 2021

Testing the EcoFlow DELTA Max with various loads to see just how much power I can get out of it before it cuts out. EcoFlow Delta Pro affiliate link (works from USA only): https://ecoflow.com?aff=138 This is a sponsored video. I'm grateful for EcoFlow's flexibility. This is so much better than being told what to say to peddle foam mattresses, razors or online courses.

EwXQ2tYNj28 | 01 Aug 2021

The new dust hood flips open so that routers that require two collet wrenches can be used with it. I tried fitting this to my wooden pantorouter. Get the dust hood at http://pantorouter.com Previous dust hood tests: http://woodgears.ca/pantorouter/dust.html http://woodgears.ca/pantorouter/dust1.html

RnUEYbSsWmA | 11 Jul 2021

Checking out my neighbour's homemade 8" jointer, which he built in the early 80's, based on Galen Winchip's jointer, published in Fine Woodworking magazine in 1981. http://woodgears.ca/jointer/reg.html

INviLWnCecY | 14 Jun 2021

Talking about some of my techniques for varnishing while preparing for the third and final coat on a project. This is with an oil based varnish, though these techniques also apply to water based varnish. http://woodgears.ca/beginner/varnish.html John Heisz has some more tips: https://www.youtube.com/watch?v=sui2oUtBza8

faQ3PeIBAjY | 07 May 2021

Using some barometric pressure sensors hooked up to a computer to measure how well the vacuum gets distributed over the area when vacuum clamping to determine if some "cloth" on top to spread the vacuum is really necessary. http://woodgears.ca/clamps/more_vacuum.html

Wx4GZlKWgWM | 19 Mar 2021

Experimenting with different blades and bandaw chatter, then modifying the most troublesome blade to have less tooth set, which, though it didn't solve the chatter problem, greatly improved the cut quality. The main culprit to chatter is too much of a hook on the blade. http://woodgears.ca/bandsaw/chatter.html

z74kONuI1OU | 16 Mar 2021

When the longest piece of wood you have isn't long enough, and you need a strong joint to make it longer, a scarf joint or similarly angled joint is a good way to join pieces end to end. http://woodgears.ca/curtain_rods/spliced.html

m5ddt3k3sqc | 11 Mar 2021

Finishing up my 26" bandsaw build after I took it all apart again for painting and varnishing. Also balancing the wheels and adding electrical wiring to it. http://woodgears.ca/big_bandsaw/paint.html Plans here: http://woodgears.ca/big_bandsaw/plans26

QmMLunBntD0 | 02 Mar 2021

Building the top enclosure for my 26" bandsaw. But I held off uploading until I finished the plans, which took some time. Top enclosure: http://woodgears.ca/big_bandsaw/top_enclosure.html Plans: http://woodgears.ca/big_bandsaw/plans26

9eRIUV94kgQ | 11 Feb 2021

Working on finishing up my 26" bandsaw. In this eposode, making the bottom enclosure and the sawdust drawer. This directs nearly all the sawdust into the drawer, making for passive dust collection. http://woodgears.ca/big_bandsaw/bottom_enclosure.html Plans for this bandsaw: https://woodgears.ca/big_bandsaw/plans26

3iHqwaeQhr0 | 05 Feb 2021

Investigating some "buncing" I get with a sharp new hook tooth blade while resawing ironwood. This problem seems to be limited to using hook tooth blades on really hard woods like ironwood, though it happens to a lesser extent with hard maple and ash. More on bandsaw resawing: http://woodgears.ca/bandsaw/resaw.html

kM9rApYil2I | 02 Feb 2021

Adding castor wheels, a blade guard, and testing it by resawing through some ironwood. http://woodgears.ca/big_bandsaw/guard26.html Plans for this bandsaw: https://woodgears.ca/big_bandsaw/plans26

W7lM3Yxugtc | 28 Jan 2021

When doing lots of clamping, the unergonomic shape of typical bar clamps gets tiring. So I made star-knobs to replace the cylindrical clamp handles on some of my more frequently used clamps. http://woodgears.ca/clamps/knobs.html

EOYvaMhidtc | 22 Jan 2021

Making the table for the bandsaw. This could have been much simpler if I just used baltic birch plywood, but I went the cheap and complicated route. http://woodgears.ca/big_bandsaw/table26.html Plans for this bandsaw: https://woodgears.ca/big_bandsaw/plans26

AnsfOHBXklQ | 18 Jan 2021

You don't need a CNC to benefit from using CAD. Using paper templates to cut out the parts exactly the way I needed them. Also used the templates to precisely position the dowel holes to mate the parts. http://woodgears.ca/big_bandsaw/trunnions.html Plans for this bandsaw: https://woodgears.ca/big_bandsaw/plans26

uOa1mgJRPWI | 12 Jan 2021

Making the blade guides for my big bandsaw. These are the same design as the ones I made for my 20" bandsaw back in 2016. http://woodgears.ca/big_bandsaw/guides26.html Plans for this bandsaw: https://woodgears.ca/big_bandsaw/plans26

n4gOs_S-dPg | 06 Jan 2021

Adding a motor mount and drive pulley to my 26" bandsaw. Some alterations to the frame were needed. Also, the motor didn't have a usable mount, so I had to clamp it to a mounting bracket with coat hanger wire. http://woodgears.ca/big_bandsaw/motor.html Plans for this bandsaw: https://woodgears.ca/big_bandsaw/plans26

f2QfVJe7yEg | 21 Dec 2020

I started this video to show why a cowling around the fan wouldn't help, but as I experimented, things got more interesting. More about my crazy 1 hp fan: http://woodgears.ca/siren/fan.html Experiments with the veturi effect: http://woodgears.ca/physics/venturi.html My other channel: https://www.youtube.com/channel/UC3_AWXcf2K3l9ILVuQe-XwQ

RypUvWvqfLs | 18 Dec 2020

Gluing up the frame for my new big bandsaw, mostly made from 2x6 material. These are much thicker than my previous bandsaws, so I modified the design to accommodate. http://woodgears.ca/big_bandsaw/frame26.html Plans for this bandsaw: https://woodgears.ca/big_bandsaw/plans26

ofxbo1b9OFg | 07 Dec 2020

Making the wheels for my new bigger 26" bandsaw I'm planning on building. To cut down on weight and inertia, I'm making these hollow. http://woodgears.ca/big_bandsaw/hollow_wheels.html Plans for this bandsaw: https://woodgears.ca/big_bandsaw/plans26

S8t9IqrNCg0 | 24 Nov 2020

Showing the process of working out the dimensions for tenon templates on the wooden pantorouter, and using the new segmented tenon templates on the metal pantorouter. http://woodgears.ca/pantorouter/setup.html Segmented templates: https://pantorouter.com/shop/segmented-mortise-amp-tenon-template-set

TSwrKT42Kkc | 16 Nov 2020

Making a hardwood table top from construction lumber and lots of hardwood scraps cut into thin strips. I can't recommend this method because it was a lot of work, but the restult is nice. More details: http://woodgears.ca/table/top.html

d33CQchZHX4 | 30 Oct 2020

Measuring air flow rates with different types of hoses hooked up to my shopvac and my dust collectors. What type of hose you use makes a big difference in terms of air flow. http://woodgears.ca/dust_collector/hoses.html

lA4FkuORKh8 | 21 Oct 2020

A router table with a large router compartment, filter and extraction blower so that the cabinet itself serves as its own dust collector. http://woodgears.ca/router_table Tilting router lift: http://woodgears.ca/router_lift Trying a snopvac on the router table instead: https://www.youtube.com/watch?v=vc5Dr_Sb25E More blower videos: Blower impeller design experiments https://www.youtube.com/watch?v=YuEaP9kyiFc Building a dust collector blower https://www.youtube.com/watch?v=LBxFNUWD2GQ Blower design experiments https://www.youtube.com/watch?v=9rqb64ryRNY blower housing shape experiments https://www.youtube.com/watch?v=INbV5ggQ93A

zg2Ju5bNEuM | 02 Oct 2020

Experimenting with caring a butt profile in a chair seat. Iterating on it and testing for comfort. Something flat on the bottom but coming up towards the edges feels best, but unless it's really deep, it doesn't add much vs. a flat seat. Given how thick a slab would be needed to make much difference, it's not really worthwhile.

Y6ygA15K5bY | 15 Sep 2020

Building sturdy wooden chairs with armrests out of oak. This is a design my dad came up with 36 years ago and made a lot of over the years. Using the oven-bent back rungs that I made in my previous video. Article to go with this video: http://woodgears.ca/kitchen_chairs/ Plans for sale here: https://woodgears.ca/kitchen_chairs/plans/index.html My random stuff channel: https://www.youtube.com/channel/UC3_AWXcf2K3l9ILVuQe-XwQ

vXkOeDg0cfU | 21 Aug 2020

Using a kitchen stove as a kiln for bending wood to make curved chair back rungs, then cutting the tenons on the end with the pantorouter. http://woodgears.ca/kitchen_chairs/bent_rungs.html

XYRIiJsdUMs | 20 Jul 2020

Building another version of my milk crate inspired wooden boxes that I last built back in 2009. The idea of the project at the time was to use all my fancy hommeade tools. This time, I used even more homemade tools and machines! More details on this build, and links to machines used http://woodgears.ca/milk_crate/again.html

TCzelJrFp9E | 02 Jun 2020

I don't like impact drivers because they are very loud, but I have come to realize they have their advantages. The bit is much less likely to slip out of the screw head (cam out), especially when you can't get the bit straight into the screw. Mostly its the intermittent torque, but some impact drivers also hammer the bit into the screw as they go.

R-FswXMcPlw | 07 May 2020

A minimalist cantilevered nightstand. Fits well over a baseboard heater but also wouldn't block a heat register underneath. And has enough room under it for a wastebasket or something else. build article: http://woodgears.ca/nightstand Free plans here: http://woodgears.ca/nightstand/plans

gGSpVJhVfKw | 24 Apr 2020

Break testing the heavy duty shelf brackets I made, also testing similar brackets using screws from the back, and using pocket holes. http://woodgears.ca/joint_strength/shelf_brackets.html

N9H3pOuaoWQ | 21 Apr 2020

This is actually the first time using the template feature of my quick set tenon jig in a project. With double mortise and tenon joints, these shelf brackets are super strong. It's more a matter of how well they are screwed to the walls. http://woodgears.ca/tenon/double_tenon.html

CECbPFxyv40 | 10 Apr 2020

Modifying two identical shelves I built in 2014 to be a better children's book case, and a better shoe rack for the other one http://woodgears.ca/shelves/shelf_boxes.html

-osZT8PB7UU | 05 Apr 2020

Tax time this year involves scanning lots of documents, but photographing is much faster than scanning. I used to always lean a tripod over a table for this, but finally built a more steady jig to accomplish this. Other camera holding jigs I have built: https://woodgears.ca/tech/pi_holder.html https://www.woodgears.ca/macro/index.html https://woodgears.ca/tripod/steadycam.html https://www.sentex.ca/~mwandel/photo/slide_photographing.html https://www.sentex.ca/~mwandel/tech/scanner.html

jwOtiCC6-es | 20 Mar 2020

Building a circuit to engage the starter winding of an induction motor at startup. Also acts as an NVR (no voltage reset) switch and automatically cuts out if the motor stalls. Using one AC relay and two light switches. http://woodgears.ca/motors/starting.html This switch is for my 1.5"x48" belt sander http://woodgears.ca/strip_sander/xl.html

mxCuUh4JIeM | 18 Mar 2020

Finishing my 1.5x48" strip sander build. Focusing on dust collection and containment, tracking adjustment, electrical and painting it. https://woodgears.ca/strip_sander/xl2.html Plans available here: https://woodgears.ca/strip_sander/plans/index.html

QeKdP-753Pg | 10 Mar 2020

Building another strip sander, this one a bit bigger, using 1.5" x 48" belts which I cut off of old 6x48" belts. Powered by an old dishwasher motor. http://woodgears.ca/strip_sander/xl.html Plans available here: https://woodgears.ca/strip_sander/plans/index.html

no-cvLCzVC8 | 02 Mar 2020

Carving a wooden pirate sword with a curved cove cut on the table saw, and a bent lamination guard. I'm calling it a pirate sword, but it's been pointed out it looks a lot like a sword from Alladin, also called "scimitar" http://woodgears.ca/sword

nuWR9FJPXlo | 20 Feb 2020

Wanting to do a shop tour, I decided to do a bit of painting first, and then things got a little out of hand. Two weeks later, I was finally able to film the shop tour. My timelapse and image flipping software is on gitub at: https://github.com/Matthias-Wandel/imgcomp To install it, instlal raspian on a raspberry pi, and from the home directory (/home/pi) type: https://github.com/Matthias-Wandel/imgcomp

4ycl0V_XFDo | 13 Dec 2019

Inspired by Pask Makes's video on the knapp joint, I made some templates to make knapp joints on the pantorouter, and built a box. http://woodgears.ca/box/knapp.html Pask makes's video: https://youtu.be/cQyOa6RSIWM More thoughts on knapp joints: https://youtu.be/MlJjsvph3r8

DAGSFp_wFLo | 19 Nov 2019

Building two contraptions for shooting the plastic caps from baby food pouches, or plastic caps from any sort of drink bottle. http://woodgears.ca/capshooter Plans for sale here ($5) http://woodgears.ca/capshooter/plans

jIurzsTw3aU | 30 Oct 2019

A hand-operated drill designed for jigging things up. http://woodgears.ca/drill/square.html Google translation of polish language website: https://translate.google.ca/translate?tl=en&u=https://www.wiertarkaiskra.pl Polish demonstration video and website: https://youtu.be/nP7dmvqJvOw https://www.wiertarkaiskra.pl The fasteners are from "ITALIANA ferramenta". The right angle geared one is "Target J10"

8s-0aoH6BbU | 08 Oct 2019

Spacing drawers consistently so that the gaps between look consistent is hard. It's easier to make precise spacers than to measure and place screws precisely. This time I just glued the spacers in place to help support the slides. http://woodgears.ca/drawers/spacing.html

nsEmoe_sUFM | 23 Sep 2019

We don't at this point have a realtor engaged yet. Nor have we decided whether it's best to sell the whole camp at once or try to break it into pieces and sell those individually. If you are interested, send me an email. More about Amogla camp at http://woodgears.ca/amogla/#forsale

pVcbpWrvYns | 27 Jun 2019

Using a DHT22 temperature sensor to investigate dehumidifier performance, and figuring out where the basement humidity comes from. http://woodgears.ca/physics/humidity.html

iX0pDsxtqZg | 07 Jun 2019

Making a special handrail for our littlest one. A baby gate would not really work on these steps, and also wouldn'g guarantee he never takes the steps. Making a fall much less likely is the best and easiest compromise. More at: http://woodgears.ca/deck/handrail.html

ovy9U8aIBK4 | 30 May 2019

I built a removable corner shelf that sits on the deck railing for a portable bbq. That way, the bbq doesn't take up too much space. http://woodgears.ca/deck/bbq_shelf.html

HeLC_5s2VV4 | 27 May 2019

Using a low voltage halogen replacement LED bulb, which can run on anything from 9 to 25 volts, wired to a cordless drill battery. Makes a cheap, bright LED worklight http://woodgears.ca/m2/worklight.html

6kK3xF1REHo | 15 Mar 2019

Using a raspberry pi, camera module, image analysis, a stepper motor and driver, and a rotating platform to automatically aim an infrared heater at me as I move around the workshop. http://woodgears.ca/tech/heater_aimer.html

jxIbrK9nq0M | 22 Feb 2019

This 3-legged stool is a geometry and joinery challenge. I'm building it with the pantorouter, which speeds up cutting the joinery, but it doesn't solve the angles, geometry and set-up isues. More at: http://woodgears.ca/stool You can get $100 off a metal pantorouter by using discount code MW3 at http://pantorouter.com You can also buy plans for this stool at: http://woodgears.ca/stool/plans

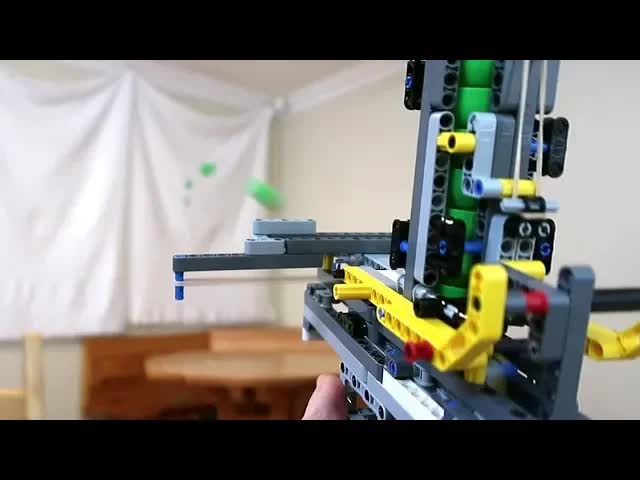

tkBfaOeOdEE | 08 Feb 2019

Building a rapid firing motorized machine catapult out of lego. Shoots about once per second, shooting plastic baby food caps. It uses a rack and pinion mechanism to tension the catapult, then pulls back the mecnaism and loads a cap before releasing. http://woodgears.ca/lego/catapult.html

-0RY6pAS3H4 | 10 Jan 2019

Building my ukulele from start to finish, compiled down from a longer series I made back in 2013. This isn't following traditional guitar building techniques. More details and free plans here: http://woodgears.ca/ukulele

SWtIFaEvwzw | 29 Dec 2018

Just some fun trying to make the most annoying sounds imaginable! I'm sure there will be many hateful comments, but it's not like I didn't warn you in the title! More about it here: http://woodgears.ca/m2/anti-asmr.html

cfcyDXwq7x8 | 21 Dec 2018

I originally built this organ in December of 1992. It's been stored the last thee years, and I only recently got it going again. One of the pipes needed fixing. More about the pipe organ at: http://www.sentex.net/~mwandel/organ/organ.html

jHOx39xJack | 06 Dec 2018

Experimenting with how small a gap a mouse can still fit through, computer controlled to make the gap a bit smaller each time the mouse goes through! http://woodgears.ca/farm/mouse_gap.html Vlog video on setting this up: https://www.youtube.com/watch?v=80liHvKMfGY

C0Syvo-lCbc | 30 Nov 2018

Taking my old mm2.1 build series and editing it down to 1/3 of its size into one 20-minute build video. I have more details on the construction of this machine at: http://woodgears.ca/mm2 And plans for sale here: http://woodgears.ca/mm2/plans

aciv1RW_4Zc | 13 Nov 2018

Assembling a laser cut plywood version of my wooden combination lock. If you buy the combination lock plans, the laser cut files are included. If you bought the plans in the past, you can use the download link sent at the time of purchase to download them. More about this here: http://woodgears.ca/combolock/laser.html You can buy the plans here: http://woodgears.ca/combolock/plans

sAJcruHekNE | 27 Oct 2018

A compilation of my box joint jig video series from 2012, edited down to one 20-minute video. http://woodgears.ca/box_joint/jig.html Part 1 of the original series from 2012: https://www.youtube.com/watch?v=LXAO7Zla44o

J_72hOY2vPg | 11 Oct 2018

My pantorouter build video series condensed into one fast-paced 25 minute video. If you would like to build your own pantorouter, I recommend watching the longer build series, and, of course, buying the plans. The plans: http://woodgears.ca/pantorouter/plans Buy a commerical metal one: http://hybridpantorouter.com Build video series 1 Linear glides: https://youtu.be/Wtx9xXyojrU 2 Pantorgraph: https://youtu.be/raq7fREYSeA 3 Template holder: https://youtu.be/mvpjMIHJ-io 4 table: https://youtu.be/ra7jdMTAhBY 5 Adjusting / first cut: https://youtu.be/3aqdD-GL1Cw 6 Plunge lever: https://youtu.be/WzZi6Me7rGg 7 Spring balance: https://youtu.be/PK79GKzQikI 8 Clam pand fence: https://youtu.be/BgijPlIgKeg 9 Reassembly: https://youtu.be/lohsz9RVYlA

x5pJCvZ1AbE | 07 Oct 2018

Finally, part 2 of the tractor shed build. I was not able to finish it due to tendonitis problems, but gave all the materials to a friend, matt carrier who erected it and filmed the process. http://woodgears.ca/shed/tractor2.html

Z2Z4FAmZA0c | 08 Sep 2018

We moved out to the country last year, but it turns out it did not make us happy. While there is much to appreciate about a big property, between maintenance, kids, having to drive for everything, no family nearby, and tendonitis problems for me, we never actually got to enjoy the property.

7KS3DbPKEdI | 02 Aug 2018

Tendonitis problems in both arms made me give up on finishing the tractor shed, and on the rural property all together. So we will be moving again, to Fredericton. The tractor shed is taken. More details at: http://woodgears.ca/misc/move.html My other (second) channel https://www.youtube.com/channel/UC3_AWXcf2K3l9ILVuQe-XwQ Other channels I mentioned: https://www.youtube.com/darbinorvar https://www.youtube.com/MikeAndLaurenTV

lohsz9RVYlA | 15 Jun 2018

Final assembly of the whole pantorouter from pieces after I had it all apart for varnishing. Timelapse with narration, plus cutting some mortise and tenons. http://woodgears.ca/pantorouter You can buy plans for the pantorouter here: http://woodgears.ca/pantorouter/plans

BgijPlIgKeg | 14 Jun 2018

Making the clamp to hold the workpiece as well as a fence. Also showing various clamping options I experiented with in the past. http://woodgears.ca/pantorouter/clamp.html You can buy plans for the pantorouter here: http://woodgears.ca/pantorouter/plans

PK79GKzQikI | 12 Jun 2018

Adding springs to help balance the weight of the router so it's less necessary to lift up on the operator handle http://woodgears.ca/pantorouter/springs.html You can buy plans for the pantorouter here: http://woodgears.ca/pantorouter/plans

WzZi6Me7rGg | 08 Jun 2018

Adding the plunge lever (useful when mortising with a spiral bit), and depth stops to the side. http://woodgears.ca/pantorouter/plunge2.html You can buy the plans for this (updated) pantorouter here: http://woodgears.ca/pantorouter/plans If you bought the pantorouter plans in the past, you can use the download link that was emailed to you at the time of purchase to download the latest version.

lMaGlR1w5YU | 06 Jun 2018

I have been mostly working on finishing up these plans the last two weeks. Finally have them finished. You can buy the plans here: http://woodgears.ca/pantorouter/plans If you bought the pantorouter plans in the past, you can re-download the latest version for free using the link that was sent at the time of purchase. You did of course keep a copy of that email, as instructed.

3aqdD-GL1Cw | 05 Jun 2018

Taking the earliest opportunity to try out my not-yet finished pantorouter to see how well it works. http://woodgears.ca/pantorouter/tweaking.html You can buy the plans for this (updated) pantorouter here: http://woodgears.ca/pantorouter/plans If you bought the pantorouter plans in the past, you can use the download link that was emailed to you at the time of purchase to download the latest version.

ra7jdMTAhBY | 01 Jun 2018

Building the table for my updated pantorouter http://woodgears.ca/pantorouter/table2.html You can buy the plans for this (updated) pantorouter here: http://woodgears.ca/pantorouter/plans If you bought the pantorouter plans in the past, you can use the download link that was emailed to you at the time of purchase to download the latest version.

mvpjMIHJ-io | 29 May 2018

New and improved template holder for the pantorouter allowing the templates to be moved vertically while ensuring that it stays level. http://woodgears.ca/pantorouter/template.html You can buy the plans for this (updated) pantorouter here: http://woodgears.ca/pantorouter/plans If you bought the pantorouter plans in the past, you can use the download link that was emailed to you at the time of purchase to download the latest version.

raq7fREYSeA | 25 May 2018

Building the pantograph mechanism for the pantorouter. http://woodgears.ca/pantorouter/pantograph2.html You can buy the plans for this (updated) pantorouter here: http://woodgears.ca/pantorouter/plans If you bought the pantorouter plans in the past, you can use the download link that was emailed to you at the time of purchase to download the latest version.

Wtx9xXyojrU | 18 May 2018

Adapting drawer slides to make the linear glides for the plunge mechanism on the pantorouter. http://woodgears.ca/pantorouter/linear.html I have covered this topic twice before: In 2014 for the pantorouter xl: https://www.youtube.com/watch?v=Ul2NfxBTVLg In 2010 for the original pantorouter: https://www.youtube.com/watch?v=mPkwIG7og44 You can buy the plans for this (updated) pantorouter here: http://woodgears.ca/pantorouter/plans If you bought the pantorouter plans in the past, you can use the download link that was emailed to you at the time of purchase to download the latest version.

MDKMwMT4T24 | 17 May 2018

I didn't film building my original pantorouter, but that pantorouter is by far the more popular machine, and I prefer it myself. I incoroporated some design improvements and some changes to make it easier to build, and I'll film building it again. http://woodgears.ca/pantorouter Buy metal pantorouter here: http://hybridpantorouter.com You can buy the plans for the (updated) pantorouter here: http://woodgears.ca/pantorouter/plans If you bought the pantorouter plans in the past, you can use the download link that was emailed to you at the time of purchase to download the latest version.

BnZAD1odYoA | 20 Apr 2018

A workbench on wheels, of sorts, but without it's own wheels. Two levers are used to lift it onto moving dollies when I need to move it. http://woodgears.ca/workbench/dolly.html

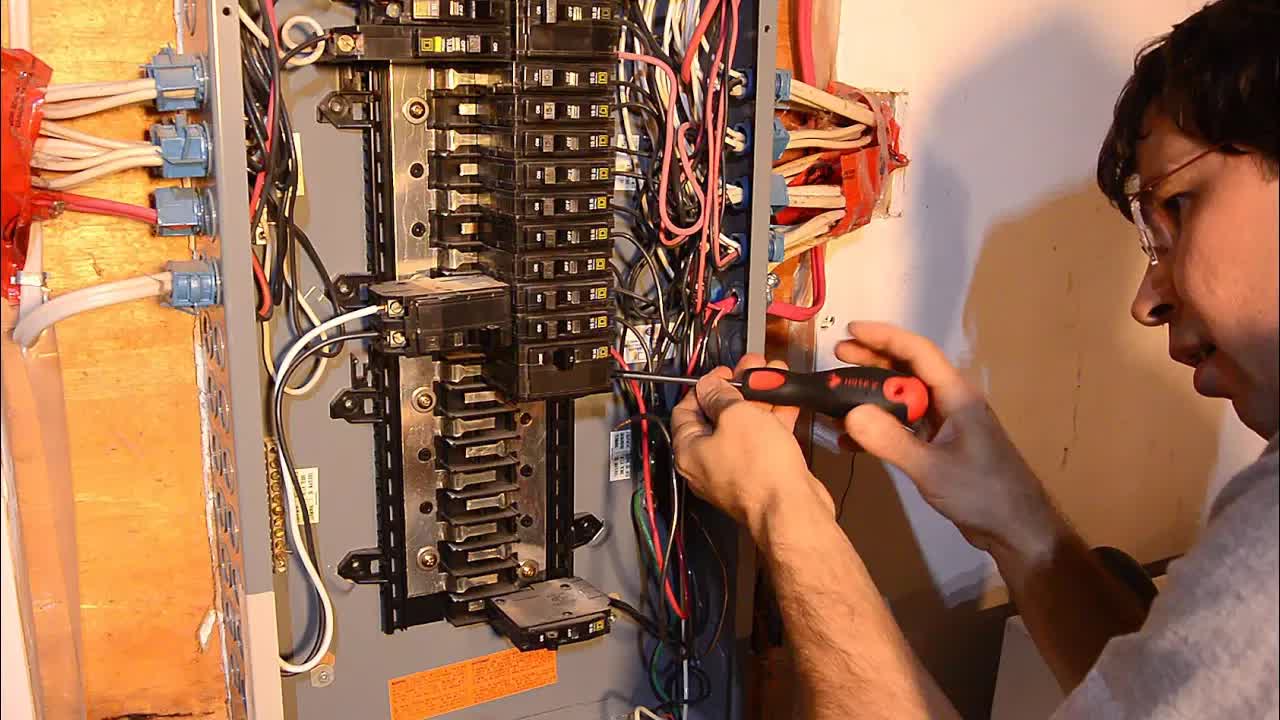

kfHB5AoAAbs | 17 Apr 2018

I needed to turn on a 120 volt dust collector whenever the 240 volt for my table saw was turned on. This relay box takes the 240 volt from the table saw to activate a relay to turn on a separate circuit. http://woodgears.ca/motors/relay_box.html

wt0u8Uu5k90 | 06 Apr 2018

My table saw was getting loud. One of the bearings had worn out. I managed to get the old ones off and the new ones out without having a press and without completely disassembling the saw. http://woodgears.ca/delta_saw/bearings.html

gBmVU5tZbWU | 02 Mar 2018

Finishing up my belt grinder / belt sander. It can take anything from 1x42" to 2x72" belts. Using a washing machine motor. http://woodgears.ca/belt_grinder/build2.html

zWx-9qteH5k | 23 Feb 2018

The first part of my belt grinder / sander build. Designed to take 1" or 2" wide belts, any length from 42" to 72". But primarily 2x72" http://woodgears.ca/belt_grinder/build1.html

UB_37encRCI | 02 Feb 2018

Experimenting with wild mice in mazes. Mice are amazingly good at traversing mazes, it turns out, so I had to make the maze more complicated. But the shrew reigned victorious http://woodgears.ca/farm/mouse_maze.html

c0riyuskak8 | 24 Jan 2018

A knife block to organize the long knives in the kitchen drawers. More kitchen woodworking projects at: http://woodgears.ca/kitchen/index.html This was an experiment with making videos differently. Took 45 minutes to make and film, but then it still took two hours to narrate and edit (boring bits are more sped up than interesting bits)

ZCbf39_ikFo | 12 Jan 2018

Attempting to time how long it takes me to build a small table saw sled. http://woodgears.ca/delta_saw/small_sled.html#time The basic sled itself took about half an hour, but then I got fancy with the safety stop, varnished it and so on.

EQT9v_aEhW0 | 05 Jan 2018

doing the standing waves on a metal plate experiment usaing only household items: A cookie sheet, computer speakers, and a tablet computer. http://woodgears.ca/physics/resonance.html

6clpdY52VZM | 22 Dec 2017

Kuldeep assembling the latest version of the Pantorouter. This one comes partly assembled right out of the box and goes together much quicker than earlier models. More details here: http://woodgears.ca/pantorouter/assembly/2018.html You can buy a metal pantorouter at: http://hybridpantorouter.com for north america, and https://www.hybridpantorouter.jp worldwide Assembling an earlier version: https://www.youtube.com/watch?v=XTmoC7TmI3w

l4VOsacFMqU | 15 Dec 2017

A friend, James, giving me a tour of the Almonte clock tower clock works. http://woodgears.ca/misc/clock_tower.html If you areinterested, James might be willing to give you a tour. His email address is "toodloo" on gmail. (if you can't figure that out, go to the bottom of the linked article)

iGXYZwZEZa0 | 08 Dec 2017

Experimenting with how small a home a mouse is able to fit through. But it didn't go as planned. I had a lazy mouse, and a hard working invading shrew. http://woodgears.ca/farm/mouse_hole.html Update: Two days later, the shrew squeezed itself through the 16.5 mm hole: https://www.youtube.com/watch?v=ifCgW1Q_rto

ik4sQS91lok | 10 Nov 2017

Have not had time to make a video of my own this week, but Timothy Wilmots just released a video about a really cool height adjustable multi-function shop cart - so if you need your fix, go watch this one instead! https://www.youtube.com/watch?v=EWEdrBdbBhg http://benchworks.be/en/projects/mfsc-multi-function-shop-cart/

utxebf1SbHE | 03 Nov 2017

A lissajous pendulum in the form of a swing, allows graphing the motion with a pen http://woodgears.ca/physics/lissajous.html A lot of people have pointed out that this video did not show up in their subscription feeds, and, indeed, initial views are lower than usual. So youtube either has a bug or is screwing around with their algorithms. Maybe hit that "bell" icon to add it to your notifications.

8WcJtovTKfE | 27 Oct 2017

Making a fence to go around a wood stove to protect small kids. This one is space saving by being fairly close to the stove, requiring a tight mesh and rigid structure. http://woodgears.ca/home/hearthgate.html

eMgmJEaYs70 | 13 Oct 2017

Explaining how a bell goes ring-gin-gin-gin (with the sound going up and down as the bell rings out). The key is multiple modes of vibration. Expanding on this, I experimented with making a bell that sounds two distinct notes, forming roughly a major third. http://woodgears.ca/physics/bell.html It turns out numberphile did a video on this topic last year, but relating to coffee cups: https://youtu.be/MfzNJE4CK_s

ZkvO99lswZg | 10 Oct 2017

When I helped my friend Paul build a cajon drum in my workshop, I got to see some beginner mistakes I normally don't even think about. But I figured these are worth covering. http://woodgears.ca/table_saw/mistakes.html

4A_HzgSA-5w | 06 Oct 2017

Helping my friend Paul build a cajon box drum http://woodgears.ca/m2/cajon.html I kind of took over towards the end because we were running out of time. Showing some woodworking mistakes. Thanks Paul for being such a good sport about it! Some of paul's pictures of it on imgur: https://imgur.com/gallery/13MfM

hbao8AWruq0 | 29 Sep 2017

I made some solid oak baseboards for our house, which I pre-varnished. Installing these was more work than the usual MDF baseboards and quarter rounds that is mostly used in new home construction. http://woodgears.ca/home/installing_baseboards.html

dDb6Ibsko6Q | 15 Sep 2017

Making lots of molding for baseboards in my house http://woodgears.ca/home/making_baseboards.html This was making over 100m (300 ft) of molding, involving lots of planing and routing. I made a homemade power feeder to help with the job.

Y0N3oWrPwwE | 01 Sep 2017

Making a friction damper to cut down on vibrations on my old contractor table saw http://woodgears.ca/table_saw/vibration.html Link belts: Lots of people suggesting these. I had used a link belt on my other table saw years ago, but gave up on it, so didn't even think to address why I didn't consider one of those. My video on link belts: https://www.youtube.com/watch?v=Nc4Mt-O5tcQ Washing machine dampers: I never took a front loading washer apart (they aren't that common in Canada) so never thought of using dampers from one of those. However, we have a front loading washing machine, and the drum on that is fairly easy to move, so not damped as stiffly as would be needed for the motor, so these probably would not work.

D-_cvpnoDGA | 18 Aug 2017

An interesting design of dishwasher pump motor, re-purposing it to be a blower motor for a small dust collector. woodgears.ca/motors/wet_rotor.html This design of motor, though not very flexible, is surprisingly efficient. Based on the comments, wet rotor motors are often used in aquarium pumps, heating circulation pumps and fountain pumps Blower housing experiments: https://www.youtube.com/watch?v=INbV5ggQ93A Dust collector blower: https://www.youtube.com/watch?v=LBxFNUWD2GQ

sLDCSzZtAH8 | 28 Jul 2017

This time building basement shelves, with a reltatively thin frame, but making up for it with double mortise and tenon joinery to hold it together. http://woodgears.ca/shelves/yet_another.html If you don't have the fancy tools, you can built something quite similar without - shee here: https://www.youtube.com/watch?v=9QeXOb9rxRY

EJpgT2VCB_w | 21 Jul 2017

A simple way to make thread taps from bolts of screws using an angle grinder. http://woodgears.ca/thread_taps To address some hostile comments: Don't have the tools to make one? For less than the cost of one "wood whisperer thread tap" you can buy an angle grinder and make one, assuming you already have a saw, a drill, and a piece of wood and a screw. But people have been using metal taps on wood for ages, I'm trying to counter the recent idea that you need extra special expensive taps for wood. Keep woodworking accessible. But if this video bothers you, please unsubscribe from my channel. I'm not there to please you, and I won't miss you. Cause I like it edgy :)

A_R9E5zcPNY | 07 Jul 2017

The workshop is now organized enough again that I could imagine doing work in it. Not fully organized, but enough so that I can put the tools away and not go crazy. http://woodgears.ca/workshop/big_garage.html

skiTggK_o90 | 05 Jul 2017

Changing over to my "good" workbench and tool wall in my big garage workshop, now that that is my main workshop. More about the workench: http://woodgears.ca/workbench Tool holders: http://woodgears.ca/tool_holders

WC-m6Rv-zQ8 | 30 May 2017

http://woodgears.ca/wiring/240-volt_plug.html Making a cord to connect a dryer socket to a smaller 240 volt plug (same kind of plug as on my table saw), but this one is for a European washer. Dryer plugs typically have a 30-amp breaker on them. You could run a motor up to 6 hp off a dryer plug. as long as the motor is 240 volt single-phase. The socket I'm using here is normally used for 15 or 20 amp applications, so the breaker and house wiring are larger than needed. This may cause the breaker to not pop if the circuit is overloaded, which may cause your wiring to overheat. The breaker will still pop for a short circuit, and the motor's thermal protection should take care of other cases. It might be a good idea to change the breaker to a 15-amp breaker, but then you would no longer be able to use the dryer socket with a clothes dryer. A lot of commenters seem to get worked up over me cutting off the neutral and connecting ground. The plug has no neutral, only ground. I connected the ground to ground. The over-capacity circuit is another thing that gets the safety nazis worked up. But - every time you plug a lamp or an alarm clock in to a socket, you have something connected to a circuit that has a much bigger breaker than needed. And your house doesn't burn down from that either. But be warned, do at your own risk. If you aren't comfortable with this, don't blow your top. Just don't do it yourself.

Ac7dAVWD_q4 | 19 May 2017

About my old Rockwell beaver 9" table saw that I bought used back in 1996, putting it back together after moving it. More about this table saw at: http://woodgears.ca/table_saw More about the mobile base: http://woodgears.ca/mobile_base/table_saw.html Sorry, no time for a project this week, but I'll have a project next week.

_cW0-fia5Hw | 16 May 2017

Using a maget and a compass to establish alignment through a floor or walls. http://woodgears.ca/shop-tricks/thru_floor_alignment.html More shop tricks: http://woodgears.ca/shop-tricks

jNta5mjsj88 | 05 May 2017

Wiring a simple remote switch cord for turning stuff on and off. http://woodgears.ca/wiring/remote_switch.html Of course you would prefer to see an elaborate woodworking project. Duh! But that's all I have time for this week.

2hjOPIG4NFk | 28 Apr 2017

Showing the layout of my basement workshop. This is the last shop tour for this workshop. http://woodgears.ca/workshop/2017.html We are moving out to the country, so my big garage workshop will be my future workshop. Shop tour 2012: https://www.youtube.com/watch?v=p9HcUV94HAs How much the machines cost: https://www.youtube.com/watch?v=TaT74Eqcau0

UiPacBQcL0o | 21 Apr 2017

Using a small handheld belt sander to refinish a floor, gap filling with shims, getting it smooth and free of specs and bumps. http://woodgears.ca/home/floor_refinish.html I learned along the way and show some of my mistakes. Not everything I tried turned out to be a good idea. But the floor turned out good, just more work than it could have been. For a while I had comments disabled. Over 1000 comments, but really it was mostly different version of the same two negative comments over and over "you should have rented a sander", and "you should have hired a professional". Both of which are already addressed at the end of the video. You can see this floor again in my domino machine video: https://youtu.be/N1-wU9NgsV4?t=5m37s

Lo2E9yxwiUQ | 17 Mar 2017

Using my big 20" bandsaw as a sawmill. The log is on sawhorses, while the bandsaw is pushed past it on a dolly. http://woodgears.ca/big_bandsaw/sawmilling.html Plans for the bandsaw: http://woodgears.ca/big_bandsaw/plans

u1WE-Fpd224 | 10 Mar 2017

Fitting drawers for my bandsaw stand, with recessed drawer pulls. Also some optimization to the passive dust collection http://woodgears.ca/tool_stand/bandsaw_drawers.html Yes, these drawers are in no way like a "bandsaw box", but I picked that title quite deliberately :)

yZfOcxgx-j8 | 28 Feb 2017

Making a short riser block for my 14" cast iron bandsaw. http://woodgears.ca/bandsaw/riser.html Dylan (woodbrew) was inspired by this to make a full 6" wooden riser block for his bandsaw: https://www.youtube.com/watch?v=rJfix_p2-Pg

aiDJp6utmUM | 21 Feb 2017

seven build videos condensed into one fast-paced video, showing every step http://woodgears.ca/big_bandsaw Plans: http://woodgears.ca/big_bandsaw/plans Individual longer videos: The wheels: https://www.youtube.com/watch?v=zBn5uyRd95o The frame: https://www.youtube.com/watch?v=HZ2IJBJcJKc Wheel mounts: https://www.youtube.com/watch?v=KAPhiWQflVw Blade guides: https://www.youtube.com/watch?v=rtBBliZfkps Table: https://www.youtube.com/watch?v=AOHnAjSq3I4 Enclosure: https://www.youtube.com/watch?v=WWOjswxPMO0 Electrical: https://www.youtube.com/watch?v=_CzSo_bU2gA Playlist of all the longer videos (over an hour) https://www.youtube.com/playlist?list=PLSnvVtM4lBIXfbqfiNyPs6L4LH302_b6G

4yzUbxVOGpU | 20 Jan 2017

Making some boxes to hold paperwork in, using a battery powered table saw, and my screw advance box joint jig. http://woodgears.ca/sp/boxes.html More about the box joint jig, and plans for the jig: http://woodgears.ca/box_joint/jig.html @DEWALTttough, #flexvolt, #ad

yei9NHvszfk | 16 Jan 2017

More about this bandsaw: http://woodgears.ca/big_bandsaw/ More frequently asked bandsaw questions: http://woodgears.ca/bandsaw/faq.html Bandsaw blade design issues: https://www.youtube.com/watch?v=V_bUCTCNUmo And of course you can buy plans for this bandsaw: http://woodgears.ca/big_bandsaw/plans

KF40KduxqeY | 13 Jan 2017

DeWalt gave me a FlexVolt table saw (sponsored). I figured the first thing to do with it is to build a crosscut sled for it. http://woodgears.ca/sp/sled.html @DEWALTttough, #flexvolt, #ad

_CzSo_bU2gA | 06 Jan 2017

More finishing touches for the bandsaw build http://woodgears.ca/big_bandsaw/finish_up.html And the plans are finally ready: http://woodgears.ca/big_bandsaw/plans I got the bandsaw sawmill blade from http://sawblade.com

mx3dZ3gvEis | 30 Dec 2016

Making a maze and using a mouse trap to force mice to find their way through it. Wild field mice in a shed http://woodgears.ca/farm/maze.html Music: Log cabin blues, performed by Anthony Savidge: http://www.anthonysavidge.com/

lWTZMgYadF4 | 23 Dec 2016

Going over a not-so-great jobsite saw. This one has qutie a few issues. I did get this saw as part of a sponsorship deal, so as a courtesy to the sponsor, I don't mention the brand. I hope some of the stuff I point out about this saw will help you in terms of what to look for when shopping for a table saw. More details on my website: http://woodgears.ca/sp/jobsite.html

Q4nP47uRckA | 16 Dec 2016

John and I testing how much force our respective long reach C clamps can exert. Sorry - disabled new comments. This video attracted far too many of the same kind of stupid comments over and over. We were ribbing each other deliberately for the video, but people assume it was a lot of animosity (you can post comments, but I have to "review" them first, which I probably won't do) My clamps: http://woodgears.ca/clamps/index.html John's clamps: http://www.ibuildit.ca/Workshop%20Projects/c-clamp-1.html Moe fun when I visited John Heisz: http://woodgears.ca/misc/heisz_visit.html

XUSs2K_-d5c | 14 Dec 2016

John Heisz demonstrating the strength of the biscuits as shelf pins. They held up well enough, until the third jump test. But analyzing the footage, it was actually the shelf that broke first. had this been shelf pins, they would have torn thru the shelf long before the biscuits failed. John's video on making the biscuit joint shelf pins https://www.youtube.com/watch?v=_UvvN9HDW3c John's edit: https://www.youtube.com/watch?v=6UYPjg-NVGs More fun with John Heisz http://woodgears.ca/misc/heisz_visit.html

CgbIlJpwpr4 | 12 Dec 2016

More about the visit: http://woodgears.ca/misc/heisz_visit.html My other youtube channel: https://www.youtube.com/channel/UC3_AWXcf2K3l9ILVuQe-XwQ John Heisz's YouTube channels: https://www.youtube.com/user/jpheisz https://www.youtube.com/channel/UCzGbp-rRVNwyFhn9gHoZr5g

WWOjswxPMO0 | 09 Dec 2016

Bandsaw blade buard, enclosure (housing), and cutting up a log to roughsawn lumber with a sawmill blade. http://woodgears.ca/big_bandsaw/enclosure Plans for sale here: http://woodgears.ca/big_bandsaw/plans The tree that this piece of log came from: https://www.youtube.com/watch?v=agv2i1hhFEI

KAPhiWQflVw | 11 Nov 2016

Building the wheels mounts, tension and tracking adjust for my big bandsaw. also attaching a small utility motor to spin it up and make the first test cuts, without any blade guides.

jgDJ_UUzMIo | 08 Nov 2016

Going over my first homemade dust collector. It works, but nothing about it is optimal. It was tempting to try to fix the flaws, but to fix all the flaws means changing most parts. So starting over made the most sense. http://woodgears.ca/dust_collector/v1.html I have a seriels of articles and videos about the new dust collector: http://woodgears.ca/dust_collector As well as plans for sale for it: http://woodgears.ca/dust_collector/plans

WLrsAIKFy0A | 02 Nov 2016

Converting my "better mouse trap" to a rat trap. But the rat was too smart for it. But lots of squirrel action. Tried to convert it to a squirrel dunking machine, but then no more squirrels would come. The vermin just wouldn't cooperate on this one! More about this style of mouse trap here: http://woodgears.ca/farm/mousetrap.html

OfkYNhe1u6M | 31 Oct 2016

Explaining why bigger is better, and issues of space and blade metal fatigue associated with 3-wheeled bandsaws. http://woodgears.ca/bandsaw/3-wheeled.html This video has prompted a whole lot of bandsaw design suggestions in the comments. I adressed the most popular ones in the associated article: http://woodgears.ca/bandsaw/3-wheeled.html#bad_idea Pekka's bandsaw: http://woodgears.ca/reader/pekka/bandsaw.html Mikiono's bandsaw: http://woodgears.ca/bandsaw/niki/index.html

s89lN8FmDSI | 26 Oct 2016

Doing some extreme load testing on one of my sawhorses, with my big tractor, then testing against an ordinary sawhorse. It would be a gross understatement to say the tractor weighs a tonne. More about this style of sahorse here: http://woodgears.ca/sawhorse

2FO9gf0xvEg | 21 Oct 2016