Channels lising page

All videos archived of Hyperspace Pirate

qv0IJM3BV9Y | 28 Jan 2026

Get The Ultimate Guide To Rebuilding Civilization at https://mdsh.io/hyperspacepirate and use promo code PIRATE10 to get 10% off! In this video, I'll be building on the work done in my last video on making a portable battery powered A/C unit (here: https://www.youtube.com/watch?v=2hSkXNEV-GU) to make a wearable personal air conditioner that circulates refrigerated water around a vest with about ~15m of silicone tubing woven into it. The refrigeration system in this video uses the same brushless-DC compressor and 8-cell lithium (32V) power supply, but instead of blowing cool air, the system acts as a water chiller, using a pair of 40mm copper CPU cooling blocks brazed together. One of the blocks is the evaporator of the refrigerant loop, while the other one has water circulated through it. I measured a peak refrigeration power of 24W with 26.4W of input power, which was done by measuring the time rate of temperature change of a known quantity of water. This wasn't done with a well insulated test setup, so there's probably a few watts more than what i measured, and it's likely that the system has a COP of around 1.0 like the A/C unit from the previous video. The two major advantages of the liquid-cooled vest approach are: - Almost all the cooling is applied directly to the body (as opposed to a system blowing cold air), allowing heat relief with the absolute minimum amount of power input - Using water as the coolant instead of air requires less of a temperature drop from ambient to achieve the same cooling effect, which in turn increases the potential efficiency of the system because of the smaller temperature differential The cooling vest was made from a porous reflective vest with 3/16 inch silicone tubes "woven" into the mesh with tiny zipties. Outdoors at 25C, after several minutes of running, the vest causes me to feel uncomfortably cool, but not shivering cold. I imagine it might need a bit more power for the brutal Florida summers, but it definitely works. The last thing i experimented with was running the system off solar power. Where there's heat, there's likely sunlight, so it seems like a natural choice to take advantage of the solar energy on a hot day for personal cooling. I did this with a pair of 25-watt solar panels wired in series. Open circuit voltage was just under 50V, but the compressor ESC and LM2596 buck converters used for the fan and pump have a maximum input voltage of 40V, so I had to use an N-channel MOSFET as a linear regulator in series with the panels to clip the voltage at 40V. The other challenge with solar power was that the system needed some sort of "cut-in" and "cut-out" points based on available power. Since open-circuit voltage isn't a good indicator of power available from the power, I instead opted to keep the panels shorted through a 50-ohm load resistor, which would allow me to measure current and turn on power to the refrigeration system based on that current value. Both the load resistor and refrigeration system and connected via. a relay controlled by an Arduino Uno. Overall I'd consider the project a success, and the next step I want to take is to use several hundred watts of solar power to run a larger refrigeration system and store the solar energy as cooling power in a block of ice. To recover the cooling power later in the day, I'll circulate glycol through a heat exchanger in the ice and a coil with a fan over it, which will only require a few watts of power to operate.

2hSkXNEV-GU | 20 Dec 2025

Click this link https://boot.dev/?promo=HYPERSPACEPIRATE and use my code HYPERSPACEPIRATE to get 25% off your first payment for boot.dev. In this video I'll show how I built a miniature battery-powered (and portable) air conditioner. This uses an actual vapor-compression cycle and *not* a solid-state thermoelectric (peltier) cooler. You could do this with a sine wave inverter and a battery connected to a regular A/C unit, but this one actually uses a compressor with a brushless motor that's designed for use in a DC circuit with battery/solar power. The refrigerant loop is brazed together with 1/4" (6.35mm) copper tubing, and the condenser and evaporator coils are sourced from tabletop icemakers (which I have a bunch of that I got for cheap from a surplus sale). The box enclosure consists of 3d-printed ABS plates that screw together at right-angles with tab blocks threaded for #6-32 machine screws. The power supply is a pair of 4-cell LiPo batteries in series, providing a nominal voltage of 32V. The compressor is usable for up to 48V, but the brushless motor speed controller (ESC) was limited to 36V. The top face has a power meter that shows battery voltage / current draw so you can turn off the unit when the battery voltage goes too low, and unlike an induction motor based compressor, this one is variable speed, which allows the refrigerant flow rate to be changed without the use of an expansion valve. The compressor is designed to use R134A as refrigerant (6.7 bar B/P @ 25C), but I was planning to use Butane (R600, 2.5 bar B/P @ 25C) as a refrigerant since i figured it would be running below the rated power. But due to a problem with my Butane order, I ended up just using Propane (R290, 9.5 bar B/P @ 25C) as the refrigerant instead, as I've done in many of my other cooling projects. I was worried that this might overload the compressor, but it managed to run just fine, even at 32V. The best use of this A/C unit is to point it directly at your face, since it's not likely to be able to have much effect on the temperature of a large room. It feels pretty similar to a car's air conditioning with the fan running on a low-medium setting. Despite the relatively small power, I was happy enough with the results that I want to do another micro DC-power cooling project, and I think I'll do the next one with solar power for chilling water. A few stats on the machine: Operating Voltage: 32V Battery Capacity: 70.4 W-hr Typical Power Draw: 42W Coefficient Of Performance (COP): ~1.0 Refrigerant: Propane (R290) Refrigerant Mass: ~10g Lowest Evaporator Temperature (Unloaded): -6.7C Evaporator Temperature (Fan Running): -12.6C (23.8C ambient) Condenser Temperature: 38.8C (23.8C ambient) Total Weight: 3.15 kg Music Used: Kevin MacLeod - Groove Groove

Ht9JzOryaKc | 20 Oct 2025

In this video I'll show how I built a CT scanner and used it to make 3d printed models of animal skeletons and internal geometry of certain objects. This was done using a commercial X-ray unit that was given to me by a Patreon member, but you can also do it with a DIY X-ray (just be very careful about radiation exposure by using a remote controlled system and being far away during the scan). The scanner uses an old phone as the camera, which is triggerd by a conductive probe that triggers the touch screen when a relay makes electrical contact between the probe and the phone case. The touchscreen probe, X-ray unit, and stepper motor turntable for the scanner are all controlled by an Arduino Uno with a simple control panel for manually moving the turntable and selecting the number of pictures to take in a 360 degree sweep. Typically a good scan should have at least 100 images, although the more the better. One of the major drawbacks of my system was that the camera is in the path of the X-ray radiation, which creates lots of noise on the image from "hot pixels". I'll eventually fix this using a system of mirrors to take the camera out of the beam, but it wasn't bad enough to ruin the quality of the scan model. The x-ray images are cropped, converted to greyscale, color-inverted, and have the brightness and contrast touched up using a batch processor plugin in GIMP. Here's a tutorial on that process: https://www.youtube.com/watch?v=lAQtItwKKvo You can also use a program like ifranview to do the batch processing. Note that the images will need to be 24-bit (or less) BMP files for the step below: The rotational images are turned into translational slices using a program called "Cone-beam backprojection tool", which you can find here: https://elektronika.kvalitne.cz/SW/graphics/cone_beam_backprojection/cone_beam_backprojection_eng.html The translational slices are then fed into a program called "3d slicer" which is a really powerful tool for visualizing CT scan data and turning it into a 3d mesh that can be used for printing. The program has a ton of really useful tools for tweaking and cleaning up unwanted artifcats from the scanning process to make a clean 3d model. The mesh is then exported as an STL file and printed. I was able to succesfully duplicate the skulls from a dead rat and a fish head, and was also able to model and print the internal geometry of a pumpkin, so the device does actually work, but it probably needs a little bit of fine tuning. Music Used: Kevin MacLeod - Lobby Time Kevin MacLeod - Groove Groove

7IkyVFxDQQw | 19 Sep 2025

Click this link https://boot.dev/?promo=HYPERSPACEPIRATE and use my code HYPERSPACEPIRATE to get 25% off your first payment for boot.dev. Also, a big thanks to Digital Properties Group (https://dpgsupply.com/) for giving me some pointers on building my Oxygen Concentrator and supplying me with 13X sieve and a big air compressor. Picking up where I left off with my 1,500W HHO torch video, I'm once again trying to devise a way to gas weld without buying oxygen and acetylene. While the HHO torch could cut, the big drawback was that it wasn't possible to weld because the water vapor exhaust caused immediate oxidation of the metal being heated. To try to get around this, I'll attempt to use residential natural gas or propane in conjunction with an oxygen concentrator to weld. The carbon content of the methane or propane fuel is sufficient to reduce the amount of oxidation that occurs and actually make a usable weld, but it's still pretty difficult to use for welding compared to acetylene. This is because methane/propane burn at around 2800C with oxygen, while Acetylene burns at around 3200C, so it can heat an area much faster. Perhaps the bigger issue is that the water vapor content of a methane flame is 2/3 (by mole), whereas with Acetylene it's only 1/3. I think this difference in water vapor content is enough to dramatically affect the quality of the weld. This is still a very useful tool for a home shop, because it can be used to cut, braze, solder, melt glass, etc. In that respect, it fulfils the same purpose as the HHO torch, but can provide significantly more heating power for the same quantity of electricity, and costs less money to build. It avoids the need for handling highly corrosive Sodium Hydroxide electrolyte solution. *NEVER* attempt to install / modify equipment on a residential gas line unless you know exactly what you're doing. Make sure the space you're working in is well ventilated and free from ignition sources / static electricity, and always ensure the gas valve is shut off before connecting new equipment. Before using new equipment, use soapy water to do a leak check on the gas connections to make sure there's no gas getting out. If you have any hesitation about your ability to handle natural gas, don't do it. This system works just as well with a tank of Propane or LPG with a regulator, like what you'd use for a grill. So, while this isn't that great as a welder, its other abilities make it a worthwhile tool around the shop, and avoiding the need to refill oxygen bottles can actually save huge amounts of money in the long run depending on what kind of work you're doing. This oxygen concentrator will be used in future projects to make LOX with a new cryocooler I'm building, and to crystalize YBCO in an oxygen furnace. Music Used: Kevin MacLeod - Lobby Time Kevin MacLeod - Backbay Lounge

Fh3kbC1otMM | 22 Aug 2025

Go to https://ground.news/hyperspacepirate for a better way to stay informed. Subscribe for 40% off unlimited access to world-wide coverage through my link. In this video I'll explain different methods of producing metallic Sodium, and then make a bunch with electrolysis of molten Sodium Hydroxide (known as the Castner process). Sodium can be made by reacting NaOH with magnesium or aluminum, but the reaction is extremely fast and violent and it's difficult to contain the products. A more steady method is to reduce Sodium Carbonate with Carbon, which gives off Sodium Metal as vapor and Carbon Monoxide. The problem with this method is that it requires temperatures in excess of 800C, and a lot of the Sodium that's prouced reverts back to Sodium Carbonate when it contacts the Carbon Monoxide. The other method(s) are to electrolyze molten salts. Industrially this is done by electrolysis of NaCl (the Downs process), but this also takes a very high temperature (at least 500C if a eutectic of NaCl and CaCl2 is used), and as I found when trying it in this video, the Sodium metal particles that are produced spontaneously ignite when they float to the top of the molten salt and contact the atmosphere, meaning that the cathode would need to be placed under inert atmosphere. The other problem with the Downs process is that the superheated Chlorine gas that's produced quick eats away the anode and creates an immensely potent smell even at just a few amps. Even operating it outdoors, the smell was intolerable. So really the most practical method for small scale Sodium metal production is the electrolysis of molten NaOH. NaOH melts at 323C, which is a relatively easy temperature to reach with simple electric heaters. When NaOH is split, it makes metallic Sodium at the Cathode, and Oxygen and Water vapor at the Anode. In theory the water vapor should boil out, but in reality some of it gets diffused in the melt, which eventually causes problems as it reacts with the produced Sodium. For this reason, the cell needs to be occasionally stopped in order to have its temperature raised to drive off the accumulated moisture. A PID temperature controller for the heater is required for this device, because Sodium is only produced in a narrow window between around 323C and 340C. Beyond 340C, the solubility of Sodium metal in the molten NaOH increases to the point that the yield becomes practically zero. My end goal is to create a Sodium-Potassium eutectic alloy to have room-temperature liquid metal, so one possible change to this system might be to run a eutectic melt of NaOH and KOH which only requires 171C. This would be an easier temperature to maintain, and might also eliminate the possibility of the alkali metals dissolving back into the melt due to the much lower temperature involved. In an 8 hour day, running the cell at 25A, I was able to collect a total of 36g of Sodium. With some improvements to the system, I think this amount could be significantly increased. Finally, safety is paramount when dealing with molten NaOH. If stray water gets into the cell, it can cause a thermal explosion that splatters the melt all over the place. If molten NaOH contacts skin, it will rapidly burn and dissolve it away, possibly even more violently than sulfuric acid. I sustained a major injury for molten NaOH splatter while I was making this video, so I can speak from experience. For this reason, always use a face shield, long pants / sleeves, and long gloves when working near the stuff. Research Sources: https://patents.google.com/patent/US4276145A/en Helpful guides I used: https://www.youtube.com/watch?v=5slj-93PkxQ https://www.metallab.net/Na.php https://www.myttex.net/attachments/1002_Sodium%20metal.pdf Music Used: Kevin MacLeod - George Street Shuffle Kevin MacLeod - Groove Groove

_nKihWAYrEM | 14 Jul 2025

Go to https://ground.news/hyperspacepirate for a better way to stay informed. Subscribe for 40% off unlimited access to world-wide coverage through my link. In this video I'll show the process of building my 1,500 watt HHO gas generator. The generator is comprised of three "modules" consisting of 21 plates (20 cells) of 2" x 6" 316 stainless steel spaced 4mm apart in a solution of 20 percent NaOH (Sodium Hydroxide). The cells are placed in a 3d-printed ABS casing to prevent leakage current from bypassing the plates through surrounding electrolyte. The electrolysis cells are sealed inside of re-purposed water filter casings that can hold large amount of pressure. Each module is powered by its own a 48-volt 12.5 amp power supply. At 48V, the modules pull 10 amps, and the system as a whole produces around 5 L/min of HHO gas. The gas is passed through a bubbler, which doesn't really clean contaminants out of the gas stream, but prevents flashback into the electrolysis cells of the modules. A mist of fine particles of sodium hydroxide exits the system with the gas, producing a bright orange flame, which would otherwise be almost invisible due to burning only hydrogen. At 2,800C, the flame is hot enough to melt steel, rocks, glass, sand, and so forth. Without excess fuel in the gas stream, the hydrogen flame is unable to weld steel because the superheated water vapor exhaust simply oxidizes the iron to black iron oxide (magnetite). However, the oxidizing flame makes the torch relatively effective at cutting steel up to 3-4mm. Naturally, I also played with exploding balloons a little bit too. Igniting HHO creates a detonation with a velocity of around 3,000 m/s, but the peak pressure is only around 20-atmospheres, meaning it's not powerful enough to do any real damage to solid material if it's unconfined. The main hazard is hearing damage, although I'd still recommend wearing eye protection when handling anything with HHO. With propane injected into the HHO stream, I think the flame could be made fuel-rich enough to weld steel (though at the expense of maximum temperature). I think the main use of this type of device is in welding/melting/cutting borosilicate glass, which could be extremely useful for people who need special custom glassware setups for chemistry. There's also the potential of integrating the head into a CNC sheet metal cutter. Music Used: Kevin MacLeod - George Street Shuffle Kevin MacLeod - Apero Hour Kevin MacLeod - Groove Groove

CLX_pQbSFFg | 07 Jun 2025

Click this link https://sponsr.is/bootdev_HyperspacePirate and use my code HYPERSPACEPIRATE to get 25% off your first payment for boot.dev. In this video I'll show how I built a hand-cranked generator capable of producing up to 3,000 volts AC from the output, and over 20,000 volts DC when it's attached to a voltage multiplier. Then, using a vacuum chamber, I'll generate plasma discharges with the high voltage, so it'll all be done by hand. The generator consists of a hand crank with a 4.5:1 overdrive gear connected to a rotor with 4 40x20 N52 cylindrical magnets. The stator consists of 8 coils in series, each with 14,700 turns of 38-gauge wire, for a total winding resistance of 25.6 kOhm. There's also a separate small coil and magnet on the rotor shaft for getting a low-voltage RPM signal that my oscilloscope can read. The coils were slowly and carefully wound with a 100-rpm gear motor running lower than the rated voltage to minimize pull force on the ultra-fine magnet wire. Each coil took approximately one hour to wind. The average resistance of each coil is approximately 3.2 kOhm and in total there's 11.4 km or 7.2 miles of wire on the stator coils. The peak voltage is ~3kV at just a little over 1,200 RPM on the rotor (unloaded). Maximum short circuit current measured by hand cranking was ~35 mA. The maximum power delivered to a load was 16W, although when adding that to the i^2R losses through the stator coils, the total power into the generator was 28W, making the whole thing a little over 50% efficient at maximum power. At lower power, the efficiency is closer to 80-90%. The main drawback of this design is that the stator coils don't use ferrous cores. This is because the rotor magnets are so strong that they would rip the ferrous cores out of their sockets and make the generator extremely difficult to turn at low RPM due to cogging. The upside to this is that the generator has practically zero startup torque, and without a load, the flywheel momentum of the rotor can keep it spinning for a relatively long time. Plasma could also be manually generated with a device called a wimshurst machine, which is an electrostatic generator, whereas mine is electromagnetic. The advantage of mine is that it can deliver more power than a wimshurst machine, and the 8 coils could also be reconfigured to different series/parallel combinations for different peak voltage/current. It also outputs alternating current, which allows it to be used in more types of circuits, whereas the winshurst machine is purely DC.

HZYWpZYuRKc | 12 May 2025

Take back your personal data with Incogni! Use code "hpirate" at the link below and get 60% off an annual plan: https://incogni.com/hpirate In this video I'll be demonstrating how nitrates can be made from the ozone generated from high voltage discharges. This is different from the "Birkeland-Eyde" process, which uses a white-hot high voltage arc to create NO2 to synthesize Nitric Acid. With the ozone method, O3 is generated from either Corona discharge or Dielectric Barrier discharge, which is similar to corona but acts over a large area. Unlike arcs or sparks, these types of discharges are non-thermal plasmas, and theoretically they don't produce any oxides of nitrogen. Rather, they create ozone from atmospheric oxygen by the following reaction: 2O2 → 2O3 The Ozone (O3) is an extremely powerful and unstable oxidizer than can be used to synthesize a number of different compounds. When added to Ammonia (NH3), it forms ammonium nitrate by the following reaction: 2NH3 + 4O3 → NH4NO3 + 4O2 +H2O The ammonium nitrate can then be used as a fertilizer, converted into nitrous oxide, used to make nitric acid, or used as part of a mixture for a blasting agent. I ran experiments with both large-gap / small area corona discharges at 150,000 volts, and small-gap / large area dielectric barrier discharges at a few volts. The dielectric barrier discharges produced more ozone per unit energy by far, which i determined by the use of an ozone meter. Unfortunately, when bubbling the ozone through a solution of ammonia, the maximum yield per unit energy was 0.33 grams of ammonium nitrate per kWh. In contrast, the maximum yield I achieved with a Birkeland-Eyde reactor was around 12.7g/kWh - nearly two orders of magnitude greater. The production of ozone still has lots of other uses that I intend to investigate in the future, such as the production of sulfuric acid directly from sulfur. It's also extremely effective and sterilizing large areas and removing bad smells due to it's ability to attack microbes and insects. This is similar to fumigating, but without the hassle of closing off an entire house. Ozone rapidly decays back into O2, so even if hazardous concentrations are present in a living space, they're typically safe after a few hours. In a future video I'll experiment with a higher power ozone generator fed by nearly 100% oxygen.

4NRkFqeO27Y | 08 Apr 2025

Click this link https://sponsr.is/bootdev_HyperspacePirate and use my code HYPERSPACEPIRATE to get 25% off your first payment for boot.dev. In this video I'll show how I built my own portable X-ray machine used for imaging electronics and other small objects. I initially used a KL-0.8-70 tube, but ended up using a KL11-0.4-70 tube for the final iteration. The anode is supplied high voltage by a 10-stage voltage multiplier using pairs of 1nF / 20kV capacitors in series and 100mA / 20kV diodes in series. Unloaded, it can output close to 120kV DC, but with the tube running, it puts out 50-70kV depending on the cathode current. The voltage multiplier is fed by a high voltage transformer driven by a ZVS driver at 24V DC. The transformer is made of 2 flyback transformer cores and has 4 turns on the primary and 750 turns on the secondary. It's voltage output is around 12kV peak unloaded. The transformer is submerged in mineral oil and was out-gassed under vacuum. The cathode heater current is supplied by an adjustable DC-DC buck converter I built. To get a good picture on the KL11-0.4-70 tube, I set the cathode current between 2.1-2.4 amps, but I found 2.3 amps to give the brightest and clearest picture. This number is highly dependent on the power of the anode power supply, and a more powerful supply would be able to provide a picture at a higher cathode current without pulling down the voltage excessively. The X-ray tube is housed inside an enclosure filled with mineral oil, which keeps it cooled, but also helps insulate the high voltage anode and block the bright light from the cathode heater (because the inside of the screen chamber needs to be as dark as possible). I also added a remote control, which allows the operator to stand far away from the machine for improved safety, and a timer circuit that limits the maximum on-time of the x-ray tube to 0.92 seconds, to prevent excessive radiation or overheating. The radiation levels immediately outside the machine were measured at ~0.5-1.0 uSv/h over a 1-minute average with a single 0.92 second shot being taken during that period. These levels fall off rapidly with distance, and at 10-15m away, a dosimeter barely registers a difference relative to background radiation. Schematic: https://drive.google.com/file/d/1Pz6mCtcKRF6M_m9eBsqdajyPbvOGoDZC/view?usp=sharing Music Used: Kevin MacLeod - Groove Groove

adTKHcrOzMU | 14 Mar 2025

In this video I'll be attempting to get the longest range possible out of a wireless power transmission system using inductive coupling. I'll start off with a "blocking" oscillator (similar to a joule theif) running off a 9-volt battery, and work my way up to a resonant half-bridge driver powered from 120 volts AC. The maximum range I achieved for lighting a single LED was 130 ft (40m), and the open circuit voltage at that range was about 2.6V. The wireless power transmitter is a 15-ft (4.6m) hexagon with 8 turns of 14-gauge wire that oscillates at approximately 145 kHz. This frequency is used because it's the resonant frequency of the coil when paired with a 1.32 nF capacitor. With a 120-volt DC input, the peak voltage across the coil can excess 10,000 volts. The reason this is possible without a transformer is because the high voltage peaks are on the opposite side of the coil from the MOSFET drivers, which only see voltage between VCC and GND. The catch is that the resonant capacitor has to be rated for the huge voltage produced (and also handle large currents), but this is relatively easy to do by using lots of small low-ESR film capacitors in series/parallel combinations. My capacitor bank used 100 33nF capacitors rated at 630VAC (2 parallel sets of 50 in series). This sort of capacitor bank looks and functions pretty much exactly the same as the "MMC" banks used on spark-gap tesla coils, and dual-resonant solid state tesla coils. By tuning the reciever coil to resonate at the same frequency as the transmitter, maximum power transfer can be achieved. I also added a diode and capacitor in parallel with the reciever's resonant caps to serve as a "peak detector" so that I could conveniently read peak voltage at resonance with a cheap handheld multimeter. The reciever I used in this video has an output impedance of about 11 kOhms, so while it's not a very good current source, it was capable of generating tremendous voltages when it was open- circuit. The major weakness of inductive coupling with air-cored coils is that the power transfer is heavily dependant on the geometry of the transmitter and reciever coils, and the power that can be recieved at a given distance falls off dramatically with reciever diameter. From an RF standpoint, these coils are basically electrically short antennas, so better coupling could probably be achieved at much higher frequencies where the coils are sized at one-quarter or one-half the wavelength of the transmission frequency. Music Used: Kevin MacLeod - Backbay Lounge

agwKNLoU6g8 | 20 Jan 2025

Click this link https://sponsr.is/bootdev_HyperspacePirate and use my code HYPERSPACEPIRATE to get 25% off your first payment for boot.dev. In this video I'll demonstrate the incredible power of electricity when it's stored at high voltage in a large capacitor bank. This device uses five 10,000 uF 400-volt capacitors in series, forming a bank with 2,000 uF and a maximum voltage of 2,000 volts. At full charge, it stores 4kJ of energy, which is approximately equivalent to the chemical energy in one gram of TNT. When the switch is closed, the capacitors dump more than 10,000 amps of current through an extremely thin wire, causing it to heat so rapidly that it explodes with tremendous pressure, causing a bright flash, a shockwave, and tremendous noise. This type of electrical explosion can be used in lieu of a chemical blasting cap, and in fact, was used to detonate the compression charges in plutonium-based nuclear weapons. Unlike a chemical blasting cap, an exploding wire can have its timing controlled down to the nanosecond-level, making it suitable for nuclear devices. Exploding wires are also used for plasma research, since the circuit can be configured to create a "Z-pinch" or "X-pinch" effect that generates large X-ray bursts and other interesting high-energy phenomena. For a given energy, an exploding wire circuit should have the largest voltage practical with the lowest capacitance possible to minimize RC time constant and discharge time, and maximize current rise time and peak current. This means, ideally, the capacitor bank should use high voltage film or oil capacitors. In reality, cost and logistics made electrolytic capacitors the most practical for this project. These have the best energy density, but suffer from relatively large series resistance and inductance. The circuit shown in this video is initially triggered using an Thyristor (SCR), but the extremely high peak current and short rise time caused the device to be destroyed, so I revered to a mechanical switch, which actually worked pretty well. I tried exploding Copper, Aluminum, Nichrome, and Magnesium. Aluminum and Magnesium had the most dramatic effect, because both ignited when superheated by the electric current, causing them to add their chemical energy to the blast. I've tried up to 500 milligrams of aluminum foil, and in every test, the aluminum is totally vaporized from ignition. I'm not really sure if there's a practical application that I can use this device for, but it's extremely fun to use, and if you don't have any fireworks for special occasions, it certainly provides a good substitute. Music Used: Kevin MacLeod - Lobby Time Kevin MacLeod - Groove Groove

AZqjMaiJZMQ | 13 Dec 2024

Head to https://squarespace.com/hyperspacepirate to save 10% off your first purchase of a website or domain using code HYPERSPACEPIRATE Yep - it's another refrigeration video. This time, instead of trying to go as cold as possible, I'm trying to go as big as possible, and I'll be building a 1,600-watt refrigeration system to freeze 25-gallon blocks of ice weighing over 200 lb. Like other refrigeration systems I've built, this system uses rotary compressors and R290 (ordinary propane) as a refrigerant. But this particular system has a twist: it uses two compressors with different power levels running in parallel. As weird as that may sound, it works perfectly. The first compressor was made for R410A, so it was underloaded when it was used with propane, but instead of replacing it, I simply plumbed a second compressor made for R22 into the same refrigeration circuit. Both compressors have their own condenser coils / fans, but the condenser outputs converge on the expansion valve (which is actually a needle valve for manual tuning). The evaporator consists of nearly 100 ft of 1/2" copper tubing, providing over a square meter of surface area for cooling. The 25-gallon pot sits inside the evaporator coil in a tub filled with a 30% calcium chloride solution to maximize heat transfer to the ice without freezing. The solution does still freeze between -10C to -15C but it makes soft, crumbly ice that's easy to remove the 25-gallon pot from. To remove the giant ice block from the cooling bath, a crane with a winch is used to hoist it up, move it clear of the bath, and lower it onto the garage floor. The pot is then flipped upside down, and as the outer surface warms, the ice inside slides clear of the pot. The Ice is then moved either by pushing or wheeling it on a dolly. The ice blocks are then subjected to various experiments for the sake of YouTube entertainment. I'm really not sure if this project has any practical use (aside from maybe a thermal battery?), but the giant ice blocks are a ton of fun to play with, especially in Florida where there's almost never naturally-occuring snow or ice. Music Used: Kevin MacLeod - Local Forecast - Elevator Kevin MacLeod - Bossa Antigua

AiHksObCLuU | 14 Nov 2024

Head to https://squarespace.com/hyperspacepirate to save 10% off your first purchase of a website or domain using code HYPERSPACEPIRATE In this video I'll show how to make Acetylene gas (C2H2) from Seashells and Driftwood. Acetylene gas is formed when Calcium Carbide (CaC2) comes into contact with water. Calcium Carbide can be made by reacting Calcium Oxide (CaO) with Carbon at temperatures in excess of 2,000C. The Calcium Oxide is produced by thermal decomposition of Calcium Carbonate (CaCO3), aka. Limestone. Seashells are mostly made of Calcium Carbonate, so they're baked in a propane furnace to produce the Calcium Oxide. The Carbon in the reaction comes from Charcoal, which is made by thermal decomposition of the driftwood. When wood is heated in the absence of oxygen, it releases a whole soup of volatile compounds including Methane, Carbon Monoxide, Carbon Dioxide, various other hydrocarbons, Methanol Vapor, Water Vapor, and also some tar and other goo. What's left behind is Charcoal, which is almost entirely Carbon, but with trace amounts of Potassium, Sodium, Sulfur, Phosphorous and a few other compounds. Once the Calcium Oxide and Carbon are produced, they're ground up together in a blender to make sure they're mixed as well as possible and have extremely small particle sizes to make the reaction progress easier. The temperature required for the reaction is too hot for an air breathing flame, and I don't have an oxy-fuel system, so I used an Electric Arc Furnace to heat the powder mixture. The arc was supplied with 31VAC from a winding added to the transformer of a 110/220V converter box, which can handle up to 3 kW. Later, I had to reduced the voltage to 15VAC after melting off the windings. There's no obvious visual indicator that Calcium Carbide has been formed, but due to the impurities in the reagents, it has a very prominent garlic-like smell that makes its presence obvious. Once the Carbide is formed, it can be added to water, and Acetylene gas will bubble out. The gas can be collected in a balloon or dissolved in Acetone, but it's unsafe to store it under pressure because it becomes unstable over 3-4 atm. If you have access to elemental Calcium, it's much easier to make the Calcium Carbide, because it only requires mixing with charcoal powder and heating in a test tube with a propane torch.

54Htg4I_ZBA | 26 Oct 2024

Head to https://squarespace.com/hyperspacepirate to save 10% off your first purchase of a website or domain using code HYPERSPACEPIRATE In this video I'll show how I improved my gyro stabilization system by switching from control-moment gyroscopes to a single passive gyroscope on a gimbal with weight shifting to develop stabilizing torque. At rest, the gyroscope is laying flat, but the gimbal is free to rotate about the vehicle's pitch axis. This causes a torque that resists any changes in angle on the vehicle's roll axis, but by itself, isn't able to keep the vehicle upright indefinitely, but rather it serves as an extremely strong roll "damper". By dramatically reducing the roll acceleration produced by a disturbing torque, the stabilizing gyroscope provides a large window of time for correcting the roll, meaning it can actually be stabilized with manual weight shifting - which i demonstrated in the first part of the video by rigging a large ballast weight on a lever to a remote controlled servo. For automated stabilization, the system uses an MPU6050 gyro/accelerometer to provide tilt angle data to an arduino nano, which applies a correction with a weight-shifting servo proportional to the magnitude of the roll error. However, this alone won't keep the vehicle upright indefinitely, because in cases where large disturbances occur, the correction torque can cause the vehicle to build up enough angular momentum that it rolls itself to the opposite extreme before the weight shifter can respond. To account for this scenario, a second input is provided to the feedback loop using the tilt angle of the passive gyroscope. The tilt angle is read by measuring the analog voltage output of a potentiometer connected to the gimbal shaft. This data could also come from the MPU6050 itself, but I thought it'd be interesting to use a direct analog measurement from a mechanical source. The more tricky part of stabilizing the vehicle comes from turns when driving forward. These might actually require a separate control moment gyro for correcting the much larger but short-term accelerations. The whole system is fed by either a 3S or 4S (12V or 16V) LiPo battery to a 620 kV brushless motor for the gyroscope and a 550 RPM dc gearmotor for the drive wheel. +5V DC is provided by an LM2596 buck converter module for the Arduino, RC Reciever, MPU6050 sensor, and servos. The gyroscope flywheel is a 80mm x 16mm brass disc. With a little more development I'm confident that this approach can be used to make a full-scale bicycle self-balancing (and remote control). Previous videos on Gyro stabilization: Passive gyro - one wheel vehicle: https://www.youtube.com/watch?v=XdVXrno-3B4 Control moment gyro stabilized monorail: https://www.youtube.com/watch?v=OpyLmIjZaxY

9MdJLTgTCSU | 09 Oct 2024

Head to https://squarespace.com/hyperspacepirate to save 10% off your first purchase of a website or domain using code HYPERSPACEPIRATE In this video I'll examine the "Autocascade" refrigeration cycle. The Autocascade cycle is a vapor-compression cycle that achieves multiple stages of refrigeration with a single compression. This is done by compressing a high-boiling and low-boiling refrigerant together. In this video, the high-boiling refrigerant is Propane or R290 (-42C at 1 atm) and the low-boiling refrigerant is Ethylene or R1150 (-104C at 1 atm). When the refrigerants are compressed and cooled back to ambient temperature, the high-boiling refrigerant will be liquefied, while the low-boiling refrigerant will still be gaseous. A phase separator uses gravity to separate the liquid from the gas. The liquefied refrigerant falls into a sump at the bottom of the phase separator, which then flows through the expansion valve or capillary tube into an evaporator, then returns to the compressor inlet. When the high-pressure, low-boiling gaseous refrigerant leaves the phase separator, it travels across the cold evaporator, causing it to condense into liquid. The low-boiling liquid refrigerant then travels to its own expansion valve or capillary tube where its pressure drops, causing it to boil and deliver the system's cooling to the load in a second evaporator. The catch is that the compressor has to be able to deliver a very high pressure in order to both condense the high-boiling refrigerant AND pressurize the low-boiling refrigerant enough that it will condense at the low-boiling refrigerant's evaporation temperature. This results in significant compressor heating, and in the case of my system, it had to be run at less than 100% duty cycle to avoid overheating. Here's a few performance figures from the device in this video: Average Power Consumption: 750W High Side pressure: 450 psi (32 BarA) Low Side pressure: 50 psi (4.5 BarA) Ultimate Temperature: -81C Refrigerant: Approximately 110g Propane and 70g Ethylene The main use of this system is to serve as a cold trap in applications that normally require expendable dry ice, such as freeze-drying or condensing certain gases at atmospheric pressure. The example I used here was condensing Ammonia gas to make Anhydrous Ammonia, which is extremely useful for making a variety of compounds. Control Board Schematic: https://drive.google.com/file/d/1NGpC69HgCdLxXWXaIiD8q-F3X98ENsUe/view?usp=sharing Music Used: Kevin MacLeod - George Street Shuffle

15ga4KMSWqU | 21 Sep 2024

Head to https://squarespace.com/hyperspacepirate to save 10% off your first purchase of a website or domain using code HYPERSPACEPIRATE In this video I'll use a steam turbine to generate electricity using a BLDC motor as a generator to create 3-phase alternating current. The turbine is machined from a brass block, with a 2" x 2" x 1" housing and 46mm diameter / 19mm wide rotor. As a nozzle, it has a 1mm orifice. The steam is generated by a flash boiler that's heated with a propane flame and fed from a pressurized water tank. A unique feature about this boiler design is that the feedwater pressurization comes from the propane fuel. The boiler evaporates approximately ~1 gram/sec of water, meaning it's *absorbing* about 2.6 kW of heat. The generator puts out a peak power of 17 watts, making it 0.65% efficient in a best case. In reality, a large portion of the heat is probably lost to the surroundings instead of heating the boiler, so the efficiency is probably even less than that. The average steam pressure right before the nozzle exit was about 60 psi (~4 bar) for the tests in this video. Huge losses were probably caused by the relatively large gaps between the turbine rotor and the housing wall. Also, the lack of a converging-diverging nozzle is probably another source of inefficiency, but I don't think I currently have the ability to machine one at such a small scale. The burner itself was probably drawing in much more air than was neccesary for combustion, meaning a large volume of air was probably just acting as a parasitic load on the burner. The power output of this thing was pretty small, but large enough to charge a phone / tablet or power a small radio, which could actually make it useful in an emergency if nothing else was available. The idea for this turbine is a development on some compressed-air turbine designs i experimented with in two videos published in 2022: https://www.youtube.com/watch?v=Yg5swK_AnbU https://www.youtube.com/watch?v=RMUHxo2TOUk Machining this thing out of metal was a lot of work, so maybe if i make a future video on steam turbines, I'll try one of those Tesla Turbine things, since those just require a big stack of thin plates.

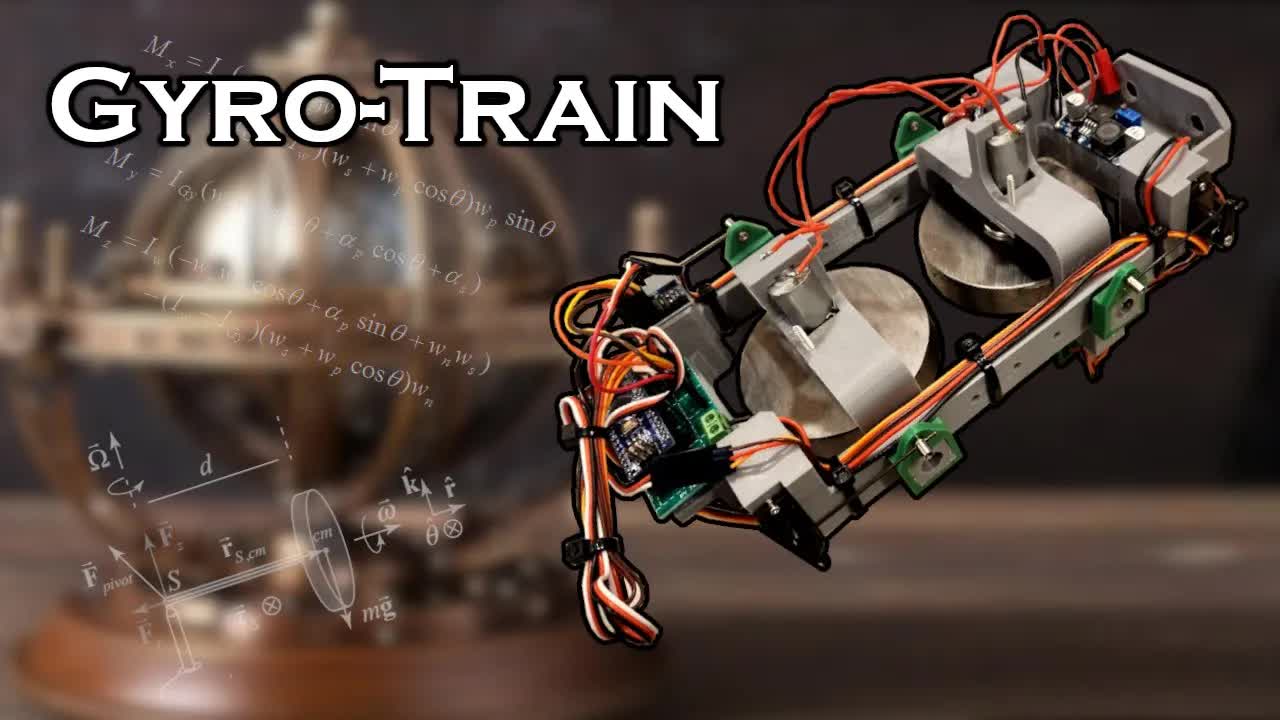

OpyLmIjZaxY | 23 Aug 2024

Head to https://squarespace.com/hyperspacepirate to save 10% off your first purchase of a website or domain using code HYPERSPACEPIRATE In this video I'll demonstrate an example of gyroscopic stabilization of a two-wheeled vehicle by building a model of the 1903 "Gyro-Monorail", which was an experimental monorail train car that used control moment gyros (CMGs) to keep it upright on two wheels. This scheme could also be used for stabilizing a bike or motorcycle, though. The end result is the same as using a reaction wheel, but rather than applying correction torque to a big wheel with a lot of inertia at near-zero RPM, the CMG uses a pair of fast spinning gyros that are tilted back and forth to correct the orientation of the vehicle from gyroscopic torque. The torque produced is a product of the angular momentum of the wheel(s) and the rate of tilt of their rotation axes. In theory this would work just fine with a single wheel, but if the vehicle experiences a change in pitch, that would cause an unwanted tilting effect (same thing as "P-factor" in airplanes). By having a pair of counter-rotating gyroscope wheels spinning at the same rate, any unwanted torque effects are canceled out. In order to produce a net torque, the wheels are tilted opposite to one another, using a pair of RC servos for each wheel. The wheels are 3" x 0.5" solid steel discs that can spin up to 8,000 RPM, but due to excessive vibration, I'm running them at a much lower speed than that. Steel discs probably weren't neccesary for this particular project, and I could have just used 3d printed discs spinning at a higher RPM. An MPU6050 gyro/accelerometer drives the servos via. an Arduino board with a little bit of code on it in order to tilt the CMGs to provide stabilizing torque on the vehicle. This could also be done with an analog circuit, or even purely mechanically, but that's a project that deserves its own video. A tiny gear motor drives one wheel of the train to make it crawl along the track. It moves relatively slowly, but the point of the project is to demonstrate the tilt stabilization, and not neccesarily to move the vehicle super fast. The motors run off a 2-cell lithium battery (approx. 8.0V), while the RC servos, Arduino, and sensor board run off of 5V supplied by an LM2596 buck converter. Even though it's a relatively simple project, the idea of seeing an unstable two-wheeled vehicle keep itself upright seems almost magical, and I'm considering scaling this up to a full-sized adult bicycle. Music Used: Kevin MacLeod - Lobby Time

7M5x2OFYP-k | 13 Aug 2024

Head to https://squarespace.com/hyperspacepirate to save 10% off your first purchase of a website or domain using code HYPERSPACEPIRATE In this video I'm going to show an easy method to extract pure copper metal from copper sulfate and then I'll melt it down and use a homemade CNC mill to machine the castings into parts. In this case, the parts were just decorative, but you could absolutely use this approach to make useful parts too. I had lots of copper sulfate laying around because I like using it to grow crystals, but you may also have some on hand if you do gardening or pond maintenance. Copper metal (Cu) can be extracted from copper sulfate (CuSO4-5H2O) by electrolysis, or by simply inserting a metal into the solution that's more reactive than copper (which is most metals). When this happens, a single-displacement reaction takes place, wherein the copper atom is dropped and the sulfate ion bonds to the other metal, leaving copper dust to precipitate out. The nice thing about dissolving metal this way is that there's no nasty fumes generated as in the case with strong acids or bases. Copper sulfate pentahydrate is 25.4% copper metal by mass, and sells for around $2/lb in the US, so if you neglect the cost of the scrap metal, that comes out to $8/lb of copper metal, which isn't too far above the the cost of copper scrap at the time of publishing this video, which is $5-7/lb in the US. As a bonus, if you used electrolysis instead of dissolving scrap metal, you'd be left with sulfuric acid after extracting the copper, which is useful on its own. The fine copper dust that precipitated out oxidized pretty quickly when I dried it, so in my first attempt to melt it, it just stayed oxidized and didn't liquify. When I mixed brazing flux powder in with the copper powder, I did succesfully manage to melt it. In total I chemically produced and melted a little over 1kg of copper for this project. Parts were cut on my CNC mill with a 1/8" end mill traveling 8mm/sec with a 0.1mm cut depth, although i later reduced that to 0.05mm because the mill isn't rigid at all, so that's something I'll need to fix in the future. It works pretty well on aluminum and brass, but struggled quite a bit with copper. Since both parts were decorative, I aged one of them by exposing it to Ammonia fumes for several days, causing deep blue copper hydroxide to form on the surface, which made it look like some sort of ancient artifact. I also experimented with fumes from Sulfuric Acid, Nitric Acid, Acetic Acid, and Hydrochloric Acid for aging, but I think Ammonia fumes gave the best appearance. In most cases this probably isn't a very practical project, but I thought it was pretty interesting to go through the process of transforming a blue liquid into solid metal parts. Music Used: Kevin MacLeod - Lobby Time Kevin MacLeod - Hard Boiled

eqxwsfy72L0 | 15 Jul 2024

Head to https://squarespace.com/hyperspacepirate to save 10% off your first purchase of a website or domain using code HYPERSPACEPIRATE In this video, I'll show how I built a cryocooler out of salvaged air conditioner parts that's able to make liquid nitrogen at -196C. The system operates on a process known as the Mixed-Gas Joule Thomson cycle. A mixture of refrigerant gases are compressed, cooled to ambient temperature, and then expanded inside a long counterflow heat exchanger. When the gases expand, they cool. Cold, low-pressure gas cools the incoming high-pressure gas causing it to drop its temperature even further, creating a snowball effect that drives the cycle down to cryogenic temperatures. The lowest temperature I've achieved is -180C with a 30/70 mixture of Propane and Argon. For higher performance, a separate vapor compression system is used to pre-cool the gas mixture to around -30C before it enters the regenerative heat exchanger. This adds complexity, but nets a performance gain, since total cooling power goes up by 30-50% with only a 15-20% increase in energy consumption. The super cold gas travels through a heat exchanger pipe in a small tank. High pressure nitrogen is pumped into the tank at up to 30 bar and liquefies at around -150C. Once the tank is filled with liquid nitrogen, it's discharged through an electronic expansion valve at the bottom of the tank into a thermos or dewar. This is different from the pure-gas joule thomson cycle in which nitrogen is expanded from 200-300 bar to atmospheric pressure to create a cooling effect. In the mixed-gas cycle, the refrigerant gases and the process gases being liquefied are two different streams. The gas mixture being used is: 25% Propane 15% Ethylene 20% Methane 20% Argon 20% Nitrogen The typical operating pressure is 400 psiG on the high pressure side and about 20 psiG on the low pressure side. Power consumption is approximately 1.4 kW, and my current production rate is about 130cc/hour of liquid nitrogen, though I'm confident this can be improved close to 300cc/hour with some adjustments. The current energy cost is about $1.29 per liter produced. For this video I've used nitrogen gas from a tank I purchased, but in a future video I'll show the process of separating out oxygen/nitrogen. Music Used: Kevin MacLeod - Groove Groove Kevin MacLeod - George Street Shuffle

4rjwx5q2fVI | 14 May 2024

To try everything Brilliant has to offer for free for a full 30 days, visit https://brilliant.org/HyperspacePirate/ . You'll also get 20% off an annual premium subscription. In this video I'm going to Liquify Methane / Natural gas with my Mixed-Gas Joule-Thomson Cryocooler. Methane liquifies at -162C under ambient pressure, but at elevated pressures, it can be condensed as high as -85C. In this experiment I'll condense some at -118C / 12 bar of pressure. My cryocooler was meant for making liquid air or liquid nitrogen, but I figured I'd try liquefying some methane along the way to see if there's any pitfalls / issues with making liquefied natural gas (LNG), which there definitely were. The joule-thomson cycle works by compressing gas and then expanding it, which forces it to drop its temperature. By back-flowing the cold low pressure gas back over the high pressure gas in a counterflow heat exchanger, the cryocooler creates a positive feedback loop that drives the temperature down into the cryogenic range. The lowest temperature I recorded was -180C. Using pure methane or pure nitrogen would require hundreds of atmospheres of pressure in the cycle to reach the desired temperature, but by using a mixture of gases with different boiling points (similar to an "autocascade" refrigeration system), the same effect can be achieved at just 20-30 bar which a repurposed air conditioner compressor can handle without any problem. For liquefying Methane, a gas mix of Propane, Ethylene, Methane, Argon and Nitrogen is used. The same components are used for liquefying Nitrogen, but in different proportions to optimize heat lift at lower temperatures. If you want to learn more about the joule-thomson refrigeration cycle, check out my previous videos on the subject: https://www.youtube.com/watch?v=r_B0RmRlFHA https://www.youtube.com/watch?v=7uQ3YW3_3eA Liquid Methane / LNG is becoming used more frequently both for power generation and vehicles because it has an energy density similar to gasoline/diesel/kerosene, but is extremely easy to ignite/burn and burns very clean. In the near future, hardware will be delivered to the moon via LNG-burning rockets (starship). At the hobby level, I don't see much use for it, but it's a fun science experiment since this is technically the first cryogenic liquid I've produced. Music Used: Mining by Moonlight - Kevin MacLeod Backbay Lounge - Kevin MacLeod Apero Hour - Kevin MacLeod George Street Shuffle - Kevin MacLeod

oI_QEbG6mDE | 11 Apr 2024

To try everything Brilliant has to offer for free for a full 30 days, visit https://brilliant.org/HyperspacePirate/ . You'll also get 20% off an annual premium subscription. This is part III of my video series on building a DIY vapor-compression casacade (i.e. multi-stage) refrigeration system. In the last two videos, i demonstrated the concepts needed to make a cascade system work and reached temperatures below -110C, but because i used low-powered reciprocating compressors meant for R600A, I wasn't able to build a system that ran continuously and only managed to evaporate low-temperature refrigerants in short bursts. This time, I'm using a pair of rotary compressors extracted from 5,000 BTU window air conditioner units. The first stage will use propane (R290) as a refrigerant, and the second stage will use Ethylene (R1150). The compressors were made for R410A, so they're able to run as high as ~30 bar continuously without a problem. This will allow me to condense Ethylene at the first stage evaporator temperature of around -20C to -25C. To extract more efficiency (and a lower temperature) out of the system, I use subcoolers on both stages; the return lines to both compressors are wrapped in capillary tubing coming from the condensers. The lowest temperature I managed to achieve with this system was only -88C, but that's probably because I ran the second stage suction pressure relatively high (around 4-6 bar) in order to keep the mass flow rate high. Down to about -63C, the efficiency or "coefficient of performance" (COP) is about 10%, so there's definitely some room for improvement. The best way to improve the ultimate temperature and/or thermal efficiency of this system would be to use a sub-cooler with a thermal gradient across it that looks basically identical to the regenerative heat exchanger in a joule-thomson system. When I experimented with this using my precooled joule-thomson cryocooler with 100% ethylene (effectively turning it into a cascade vapor compression system), I achieved nearly twice the thermal efficiency of the device I built for this video. I originally planned to use this system to liquefy Methane. This is possible at -88C, but would require a very high pressure, and with the marginal cooling power at that temperature, it's probably not practical, so I'll be doing that in my next video using my joule-thomson cryocooler. I'd also recommend using a higher-boiling refrigerant for the second stage - like R508 (if you can get it), Ethane (R170), Nitrous Oxide (R744A), or even Carbon Dioxide (R744) (although CO2 is only feasible if you keep the second stage evaporator ABOVE the -56C). The boiling points of Ethylene and Propane are far enough apart that the system is reaching pretty far. Music Used: Kevin MacLeod - George Street Shuffle Kevin MacLeod - Bossa Antigua Kevin MacLeod - Lobby Time Kevin MacLeod - Elevator

zRrgvYJ8gAY | 02 Mar 2024

Head to https://squarespace.com/hyperspacepirate to save 10% off your first purchase of a website or domain using code HYPERSPACEPIRATE Original Ethylene production video: https://www.youtube.com/watch?v=UKFEbYdKdJg Board Schematic: https://drive.google.com/file/d/1jGZg0plUJJzqGkXVEZyQ5Ky7ZHtwXC8n/view?usp=sharing Arduino Code: https://drive.google.com/file/d/12d2MGy-z9415vCw4UUFIL6S_Q7bAi6pA/view?usp=sharing In this video I'll show how I automated the process of producing Ethylene (C2H4) gas for use as a refrigerant. Ethylene is known as Ethene, but is different from Ethane which is C2H6. My original process used a manually controlled flame from a propane burner to heat a catalyst pipe full of aluminum oxide to decompose ethanol vapor into Ethylene and water vapor and fill a beach ball with the Ethylene gas, which I'd later pump into a tank under pressure. This process was time consuming, inefficient, and required constant attention to keep the flame at the right level to maintain temperature. I use a lot of Ethylene gas to test refrigerant mixes for my cryocooler, so it was worth the time to make the process hands-off. The new catalyst pipe is a 1-3/8" x 24" aluminum tube with 8 135W band heaters clamped to it. 1/4" aluminum tubes are brazed to the catalyst pipe to serve as the inlet / outlet. The band heater section is insulated to maintain temperature, but the ends of the pipe are exposed to keep them cooler to avoid melting the aluminum brazing alloy. The temperature of the catalyst pipe is controlled by a PWM signal from an arduino to a solid state relay driving the band heaters, with feedback from a thermocouple in the middle of the pipe. The target temperature I used in this video was 450C. Lower temperatures will make a higher percentage of Diethyl Ether, and higher temperatures will create Hydrogen and Carbon, and possibly damage the catalyst pipe. The ethanol vapor is supplied by a 1L boiler which is quickly brought up to its boiling temperature with a 100W heater and then sustained by a 30W heater. Feedback for the boiler heater control is provided by a thermistor inside the boiler. If the temperature inside goes over the boiling point of the ethanol, the program assumes the liquid has been depleted, and shuts off. The average production rate of Ethylene gas is around ~40L/hr depending on the temperature used for the reaction. One issue i ran into early on was that I used denatured alcohol from the hardware store, which i discovered was up to 60% methanol. This still creates Ethylene, but it also creates several other Alkenes from CH2 chains. I solved this problem by using Bio-ethanol, which appears to be azeotropic 96% ethanol without additives. The ethylene is automatically pumped into a pressure tank when the gas pressure pushes up the piston of a 500 ml syringe until the piston trips a limit switch that triggers a compressor to turn on. At the time of this video's making, I've created nearly 1,000L of ethylene gas, a lot of which i've liquefied for cryogenic experiments. Later, this gas will be filtered, dried, then used as refrigerant in a cascade vapor compression system, and as a component in my mixed- gas joule-thomson cryocooler. Music Used: Kevin MacLeod - Bossa Antigua Kevin MacLeod - Lobby Time Kevin MacLeod - George Street Shuffle

C3LCjp_REYA | 07 Feb 2024

Head to https://squarespace.com/hyperspacepirate to save 10% off your first purchase of a website or domain using code HYPERSPACEPIRATE In this video I'll show how to make Ethane gas (C2H6), also known as refrigerant R170. This is the slightly heavier cousin of Ethylene or "Ethene" which is C2H4 (Refrigerant R1150). Ethane has a boiling point of -88C compared to Ethylene's -104C. The main motivation behind synthesizing Ethane was to have a refrigerant for the second stage of a cascade vapor compression system that could still reach ultra-low temperatures, but without as high of a pressure demand. Assuming a heat exchanger temperature of -20C on the first stage of a cascade system, it would take 25.3 bar or 352 psi to condense Ethylene, whereas Ethane would only require 14.2 bar or 191 psi. This means that a small system using the relatively weak reciprocating compressors from a mini-fridge or tabletop ice-maker could use Ethane for a second stage, whereas Ethylene would typically require a rotary compressor to handle the higher pressure. Industrially, Ethane is produced from crude oil or by hydrogenation of Ethylene. The hydrogenation reaction occurs by passing Ethane and Hydrogen over a high temperature nickel catalyst. In theory this process could be done by an amateur/hobbyist, but there's actually a simpler method - electrolysis. When an acetate solution undergoes electrolysis with a platinum anode (whether acetic acid, or some acetate salt), the acetate ions break up into Carbon Dioxide (CO2) and Ethane (C2H6), in a process known as Kolbe electrolysis. This is actually a pretty complicated process that involves a lot of organic chemistry that I don't understand - but it works. In this video, I'll use Sodium Acetate as my electrolyte. Theoretically, straight Acetic Acid (or vinegar) can be used, but its electrical conductivity is extremely low, so Sodium Acetate is a better option. Over time, as the acetate ions are consumed, the Sodium Acetate becomes Sodium Carbonate, causing the solution to become basic (pH over 7.0). Once this happens, the Kolbe electrolysis process stops, and regular alkaline water electrolysis occurs, producing oxygen gas at the anode. For this reason, the electrolyte needs to be made with a generous excess of acetic acid, and the reaction should be stopped if the cell pH goes above around 6-7. Since the gas output contains CO2, it has to be scrubbed with Calcium Hydroxide in order to extract the pure Ethane. I also included a dessicant canister in line with my scrubber, since the gas has a significant amount of moisture in it. To demonstrate its refrigeration properties, I compressed my Ethane into a ~100cc pipe in an ice bath to force it to liquify, then discharged it through a valve. When the liquid Ethane is brought down to 1 atmosphere, it flashes to vapor and drops its temperature to -88C. One additional advantage of Ethane over Ethylene is that it can be stored in liquid state at room temperature, since its critical point is 32C. At 25C, liquid Ethane has a pressure of 41.9 bar or 593 psi, so it could easily be stored in a tank meant for CO2 or Nitrous Oxide, which have much higher pressures in their liquid state at room temperature. Link to Ethylene Synthesis video: https://www.youtube.com/watch?v=UKFEbYdKdJg Music Used: Kevin MacLeod - Bossa Antigua Kevin MacLeod - Lobby Time Kevin MacLeod - Groove Groove Kevin MacLeod - George Street Shuffle Kevin MacLeod - Hard Boiled

f6mLykQjxZ0 | 08 Jan 2024

Head to https://squarespace.com/hyperspacepirate to save 10% off your first purchase of a website or domain using code HYPERSPACEPIRATE In this video I'll be showing how to produce mild refrigeration with compounds extracted from urine. Human urine contains 1-2% urea (CO[NH2]2), which I'll be convert into Ammonia (NH3). This can be done either by thermal decomposition of solid urea after it's been distilled out of urine, or by reacting urine with sodium hydroxide (NaOH) and heating it. I opted for the second method, since it's less energy intensive. Videos showing the extraction of ammonia from urine often concentrate the urine by a factor of 10-20 before adding sodium hydroxide, but I found this method to be too time consuming and liable to overflow from excessive foam. Instead, I found it worked best to simply react un-concentrated urine with sodium hydroxide and heat it. Also, the smells produced from this approach are relatively mild. The only downside is that numerous batches of urine need to be processed. Once Ammonia is obtained, there's several ways it can be used for refrigeration. Anhydrous ammonia can be used as the refrigerant in a vapor-compression system and has a temperature/pressure and phase behavior almost identical to propane. Aqueous ammonia can be used in a heat driven vapor-absorption system, and Ammonium Nitrate (NH4NO3) can be used as a "cold pack" by endothermic dissolution in water. In this video I'll be using the third method, because I wanted to investigate a heat-driven refrigeration system, and endothermic dissolving seemed like a simpler approach than vapor-absorption. The Ammonium Nitrate is produced by reacting it with Nitric Acid (HNO3). I produced the nitric acid by the "Birkeland-Eyde" process, which uses a high voltage arc to ionize oxygen and nitrogen in the air, after which a certain percentage of those atoms recombine to form Nitric Oxide (NO) gas. The nitric acid quickly combines with more oxygen to form Nitrogen Dioxide (NO2), which is bubbled through distilled water. When Nitrogen Dioxide interacts with water, it forms Nitric Acid. This is a very slow and energy intensive process, but has the advantage that it allows the production of nitrates quite literally out of thin air. I should note that in small quantities, Ammonium Nitrate is actually pretty safe to store and handle, and even if it's heated directly with a blow torch, it just melts and then decomposes into Nitrous Oxide (N2O) and water vapor. To produce refrigeration, the ammonium nitrate is dissolved in water in a thin-walled aluminum can and placed into contact with a large water reservoir inside a foam container. The water reservoir acts as a thermal reservoir. Once the solution has absorbed as much heat as it can from the water reservoir, it's removed and then recharged by boiling off the water, cooling in a water bath, and then adding new water into the dry salt. In theory this works pretty well, but in reality i found that the boiler didn't work fast enough to keep the fridge temperature dropping, so really there need to be multiple cans on a rotation for this to work well. By creating a saturated solution of aqueous ammonium nitrate, I was able to produce a temperature drop to near freezing (about 3.8C) in an aluminum bottle, but only reached a minimum temperature of 13.5C in the fridge. Pretty poor performance, but at least I was able to cool off a soda a little bit. I also tested a few other substances to act as "instant cold" packs by mixing saturated solutions, and these are the temperature drops I recorded: Sodium Chloride: -1.6 C Potassium Nitrate: -11.1 C Potassium Chloride: -13.1 C Sodium Nitrate: -16.4 C Ammonium Chloride: -17.0 C Urea: -19.6 C Ammonium Nitrate: -20.4C Music Used: Kevin MacLeod - Lobby Time Kevin MacLeod - Hard Boiled Kevin MacLeod - George Street Shuffle Kevin MacLeod - Groove Groove

JN_7KgdB1V8 | 05 Dec 2023

Get Surfshark VPN at https://Surfshark.deals/HYPERSPACEPIRATE and enter promo code HYPERSPACEPIRATE for a Holiday Special offer of 5 extra months for free with the Surfshark One package! In this video I'm going to turn seashells into dry ice. Sea shells are mostly made up of limestone - or Calcium Carbonate (CaCO3), which can be decomposed into Calcium Oxide (CaO) and Carbon Dioxide (CO2) when heated to around 900C. I used a 500W induction heater i built to heat a sealed pipe full of sea shells to a hot enough temperature and collected the CO2 gas into a beach ball by using a vacuum pump to extract it from the pipe. For limestone decomposition to occur at a reasonably fast rate, the temperature really needs to be over ~1000C, so this process took several hours (even for only ~50 grams of limestone) and required a vacuum pump to pull off the CO2. I broke down the remainder of my sea shells by dissolving them in vinnegar, and saved the Calcium Acetate biproduct for later use as a solid fuel for camping/hiking. Once I collected a decent volume of CO2, I used a refrigeration compressor to pump it into a plate-stack heat exchanger and used a propane-based vapor compression refrigeration system to chill the high pressure CO2 down to about -30C, so it required only modest pressure to liquify. The refrigeration system is actually the pre-cooler stage for my joule-thomson cryocooler, which i borrowed for this video. Once a decent mass of CO2 has been pumped into the heat exchanger and liquified, it's discharged through a ~1mm diameter capillary tube into a thermos with a glass wool baffle to stop high speed gases from carrying away tiny particles of the ice. With a little bit of improvement to the limestone furnace temperature, and some minor tweaks to my refrigeration system, this could be an extremely cheap way to make dry ice, assuming a limestone source is available. With the right setup, costs could be as low as a few cents per pound of ice. Induction Heater Schematic: https://drive.google.com/file/d/1WWGMMiXeocOpjPDXXiNxOdZxMykq30Rp/view?usp=sharing Music Used: Kevin MacLeod - George Street Shuffle Kevin MacLeod - Groove Groove Kevin MacLeod - Lobby Time

udIEGE5mfcA | 20 Nov 2023

In this video I'll explain how a Magnetron works, collect some current/voltage numbers on a typical household magnetron from a microwave oven, and show how to power one off a 12V battery. Typical DIY magnetron videos only show how to remove the transmitter from the microwave oven and run it with its original circuitry off mains power. Here, I'm basically building a high frequency inverter circuit to run off DC so that the entire device is portable. To do this, I have a ZVS oscillator driving a transformer primary, and the secondary coil is connected to a voltage doubler / rectifier to provide about 3.6 kV DC. There's also a low voltage / high current winding on the transformer to provide power for the Magnetron cathode filament. One of the biggest frustrations of this project was trying to deliver enough current to the Magnetron cathode filament with my ZVS flyback transformer. It took a lot of messing around until i discovered that the filament has some RF chokes in series with it, giving it about 2.8 uH of inductance. At 40 KHz, this inductance resulted in too much impedance for enough current to flow. Fortunately, the fix was as simple as adding about 7 uF of capacitance in series with the filament to cancel out the inductive reactance. With a proper waveguide, the microwaves could theoretically be focused into a relatively narrow beam, due to their small wavelength. However, that's a project in and of itself, which I'm not going to tackle in this video. Output power of the 12V circuit in this video is only around 50-60W, but it can easily be increased by using a larger capacitor value in series with the voltage doubler on the transformer output. Be sure to use metal shielding around yourself and valuable electronics if you do this. Schematic Link: https://drive.google.com/file/d/1MyQgRyLYlGqkrFBLRWcR7STFDM9IlVSg/view?usp=sharing Music Used: Local Forecast - Elevator Kevin MacLeod - Bossa Antigua Kevin MacLeod - Lobby Time Topher Mohr and Alex Elena - Fortaleza

oIWgzVaGn4Y | 04 Oct 2023

In this video I'll show how I built my Hydrogen gas generator using electrolysis of a 10% Sodium Hydroxide solution with 316 stainless steel electrodes. Unlike an "HHO" generator, this cell separates the hydrogen from the oxygen, so it can be collected in a tank for later use. In the video, I demonstrate its usefulness as a lifting gas for a camera-carrying balloon, but my ultimate goal is to liquify it with a cryocooler at -252C or use it as a working fluid in a stirling cycle to serve as a cheap and plentiful substitute for helium. I'm also interested in using it to manufacture synthetic methane by combining it with CO2 in a process known as the Sabatier reaction. The theoretical voltage required to separate water by electrolysis is 1.23V, but in reality it will end up being 1.5-2.0 volts, depending on the electrolyte and electrode chemistry, as well as cell temperature. In order to maximize efficiency and minimize the occurance of heating and side reactions, the voltage on a cell should be kept as low above this threshold as possible. Most industrial devices have a cell voltage somewhere between 2.2-2.5 volts. The efficiency of electrolysis is approximately the threshold voltage divided by the cell voltage. The calculation to approximate hydrogen production rate is: Liters per hour = V_threshold * Current * 3600 / 287,000 * 24 The production rate of oxygen gas is half this amount. One potential pitfall of hydrogen storage in pressure vessels or use as a working fluid in cryocoolers / heat engines is the tendency for atomic hydrogen to work its way into the crystal lattice of metals and cause it to become brittle, similar to how adding carbon to steel makes it more brittle. Supposedly this can be mitigated by ensuring the hydrogen gas is totally dry, and aluminum / copper seem to be far less affected by this issue than steel. It's important to remember that if you're using stainless steel electrodes, over a long period of time, they can degrade and release toxic chromium salts into the electrolyte, some of which may be the hexavalent (Cr6+) form of Chromium. This electrolyte can't be dumped down the drain. To dispose of it properly, you need to evaporate the water and deliver the precipitate to a hazardous waste disposal site. Aqueous solution conductivity chart: https://pdfs.semanticscholar.org/cbc5/22cf4c5e6e690ca48984314c231f6643ee81.pdf Music Used: Fortaleza - Topher Mohr and Alex Elena

7uQ3YW3_3eA | 10 Sep 2023

In this video, I'll build on my progress from the last Joule-Thomson cryocooler video and reach a temperature of -153C on a single stage using parts sourced from window A/C units and common/cheap substances as refrigerants (a mixture of Propane, Ethylene, and Methane). This temperature is low enough to condense any gas except for Hydrogen, Helium, or Neon, at the following pressures: Nitrogen - 25.3 barA (352 PsiG) Air - 20.2 barA (278 PsiG) Oxygen - 10.3 barA (135 PsiG) Methane - 1.9 barA (13 PsiG) I tested several different mixtures to achieve this temperature, but the best performing I've found so far has been a 30/20/50 blend of Propane, Ethylene, and Methane, respectively. The Propane comes from an ordinary grilling tank, the Ethylene is produced by heating denatured alcohol over a catalyst, and the Methane comes from residential natural gas. All these sources are very cheap. For a throttling valve to achieve the Joule-Thomson effect, I use a 1m long 1mm ID capillary inline with a computer-controllable electronic expansion valve (EEV) used for fine-tuning flow resistance. I avoid using *only* an EEV due to the relatively large thermal conduction losses experienced through the bulky metal valve body. The system is charged with 180 PsiG (11.3 BarA). With the EEV wide open, the high/low side pressure is ~400/65 psiG (28.6/5.5 barA) respectively. With the EEV closed as far as possible without shutting off the flow, the high/low side pressure is ~520/10 psiG (36.9/1.7 barA) respectively. A temperature drop of 20-35°C across the EEV+capillary restriction is typical. I use a vacuum enclosure to thermally insulate the cold end of the system, but since I can't reach a vacuum much higher than about ~2 mBar, the vacuum isn't a very effective insulator, so I still had to pack the enclosure and wrap the heat exchanger coil with glass wool. Research papers on this subject claim pressures on the order of 10^-4 mBar inside the vacuum enclosure, which I'm unable to produce. While the temperature I've achieved is low enough to make liquid nitrogen / oxygen / methane under pressure, the heat exchanger I assembled to do so on the cold end was ineffective, so I didn't liquify any gas in this video. In the next part of this series, I'll focus on mixture optimization (by adding varying percentages of Butane and Nitrogen or Argon to the mix), increasing cooler power / temperature drop by use of a pre-cooler, and construction of a cold head that incorporates a large "reservoir" for accumulating several hundred CC of liquified gas before discharge to atmospheric pressure. If this project is succesful in producing decent quantities of liquid Nitrogen, I'll turn my focus toward production of Liquid Hydrogen using a Joule-Thomson system with LN2 pre-cooling.

-qWQaX8_EDY | 21 Aug 2023